Extrusion efficiently produces metal profiles with consistent cross-sections, ideal for large-scale manufacturing and cost-effective material usage. CNC machining offers precision and flexibility, enabling complex shapes and tight tolerances that extrusion cannot achieve. Choosing between extrusion and CNC machining depends on production volume, design complexity, and required mechanical properties.

Table of Comparison

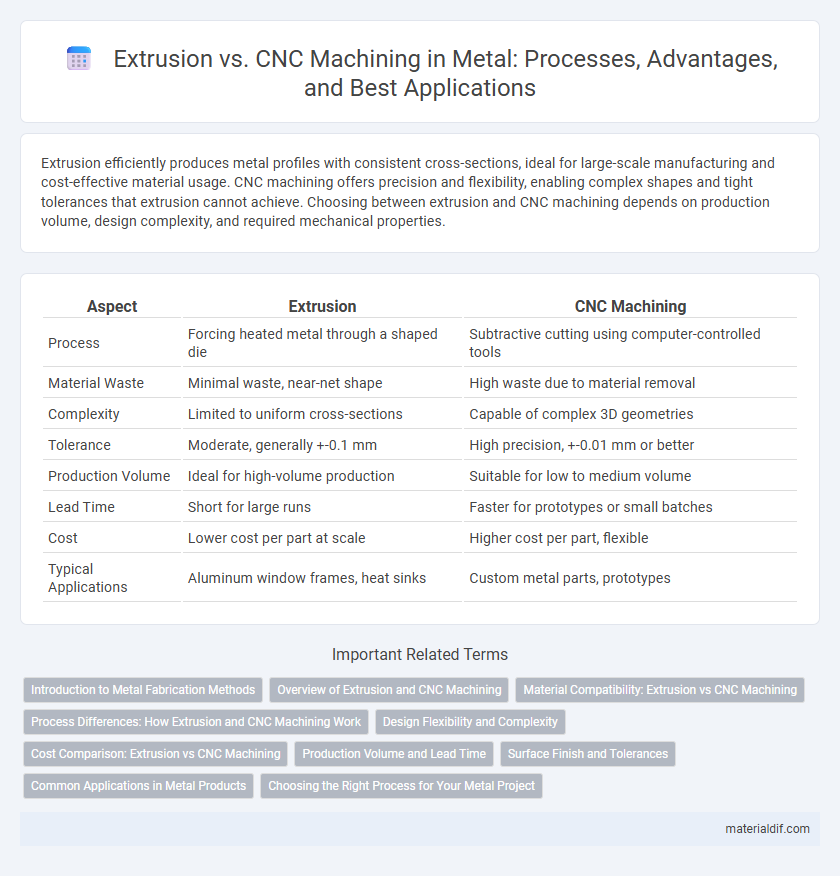

| Aspect | Extrusion | CNC Machining |

|---|---|---|

| Process | Forcing heated metal through a shaped die | Subtractive cutting using computer-controlled tools |

| Material Waste | Minimal waste, near-net shape | High waste due to material removal |

| Complexity | Limited to uniform cross-sections | Capable of complex 3D geometries |

| Tolerance | Moderate, generally +-0.1 mm | High precision, +-0.01 mm or better |

| Production Volume | Ideal for high-volume production | Suitable for low to medium volume |

| Lead Time | Short for large runs | Faster for prototypes or small batches |

| Cost | Lower cost per part at scale | Higher cost per part, flexible |

| Typical Applications | Aluminum window frames, heat sinks | Custom metal parts, prototypes |

Introduction to Metal Fabrication Methods

Metal fabrication methods such as extrusion and CNC machining play crucial roles in shaping raw metal into precise components. Extrusion involves forcing heated metal through a shaped die to create long objects with uniform cross-sections, ideal for producing pipes, rods, and complex profiles efficiently. CNC machining utilizes computer-controlled cutting tools to remove material from solid metal blocks, offering high precision and versatility for intricate designs and tight tolerances in various industries.

Overview of Extrusion and CNC Machining

Extrusion is a metal forming process where heated metal is forced through a die to create long objects with a fixed cross-sectional profile, ideal for producing consistent shapes like rods, tubes, and channels. CNC machining involves subtractive manufacturing, where computer-controlled tools precisely cut and shape metal from a solid block, offering high accuracy and complexity in parts. Both methods serve different production needs: extrusion excels in volume and uniformity, while CNC machining provides detailed customization and tight tolerances.

Material Compatibility: Extrusion vs CNC Machining

Extrusion excels with aluminum, copper, and magnesium alloys, offering consistent cross-sectional profiles and high material efficiency. CNC machining handles a wider range of metals including steel, titanium, and alloys with complex geometries requiring precise tolerances. Material compatibility in extrusion is limited by the need for ductile metals, while CNC machining accommodates both ductile and hard materials due to its versatile cutting tools.

Process Differences: How Extrusion and CNC Machining Work

Extrusion involves forcing heated metal through a shaped die to create continuous profiles with consistent cross-sections, ideal for producing long, uniform parts efficiently. CNC machining uses computer-controlled cutting tools to precisely remove material from a metal block, enabling complex geometries and tight tolerances. While extrusion shapes metal by deformation, CNC machining achieves detailed customization through subtractive processes.

Design Flexibility and Complexity

Extrusion excels in producing continuous profiles with uniform cross-sections, ideal for simple to moderately complex designs requiring high repeatability and cost efficiency. CNC machining offers superior design flexibility, enabling the creation of intricate geometries, tight tolerances, and complex features that extrusion cannot achieve. For parts demanding detailed customization and complex shapes, CNC machining provides unmatched precision and versatility.

Cost Comparison: Extrusion vs CNC Machining

Extrusion generally offers lower initial tooling costs and faster production rates, making it more cost-effective for large volume metal parts with consistent cross-sections. CNC machining incurs higher labor and machine operation expenses due to its precision and versatility, which increases costs per unit, especially for complex or low-volume runs. When comparing overall expenses, extrusion is preferred for cost efficiency in mass production, while CNC machining suits projects demanding high precision and customization despite higher costs.

Production Volume and Lead Time

Extrusion offers high efficiency for large production volumes with shorter lead times due to continuous shaping processes, making it ideal for mass manufacturing of consistent metal profiles. CNC machining excels in low to medium production volumes by providing precise, customizable parts with relatively longer lead times due to its iterative, tool-changing operations. Choosing between extrusion and CNC machining depends on balancing required production volume and acceptable lead time against the complexity of the metal component.

Surface Finish and Tolerances

Extrusion produces consistent surface finishes with minimal tooling marks, ideal for large metal profiles but generally offers looser tolerances around +-0.5 mm. CNC machining achieves superior surface finishes with smooth, precise contours and tight tolerances often within +-0.01 mm, making it suitable for intricate, high-precision metal components. Surface quality from CNC machining allows for finer detailing and tighter dimensional control compared to the more uniform but rougher finish of extrusion.

Common Applications in Metal Products

Extrusion is widely used for manufacturing complex cross-sectional metal profiles such as aluminum frames, heat sinks, and tubing, often favored in automotive, aerospace, and construction industries for lightweight structural components. CNC machining excels in producing precise, intricate metal parts like gears, custom brackets, and engine components, commonly utilized in aerospace, medical devices, and industrial machinery where tight tolerances and complex geometries are critical. Both processes serve distinct roles in metal product manufacturing, with extrusion suited for continuous shapes and CNC machining ideal for detailed, high-precision parts.

Choosing the Right Process for Your Metal Project

Extrusion and CNC machining offer distinct advantages for metal projects depending on design complexity and production volume. Extrusion is ideal for creating continuous profiles with uniform cross-sections, allowing cost-effective mass production of shapes like tubes and rods. CNC machining excels in precision and versatility, enabling intricate, custom components with tight tolerances and complex geometries from solid metal blocks.

Extrusion vs CNC Machining Infographic

materialdif.com

materialdif.com