Hot rolled metal undergoes processing at high temperatures, resulting in a rough surface and looser tolerances, making it ideal for structural components. Cold rolled metal is processed below its recrystallization temperature, producing a smoother finish with tighter tolerances and enhanced strength, suitable for precision applications. Choosing between hot rolled and cold rolled metal depends on the required mechanical properties, surface quality, and cost considerations.

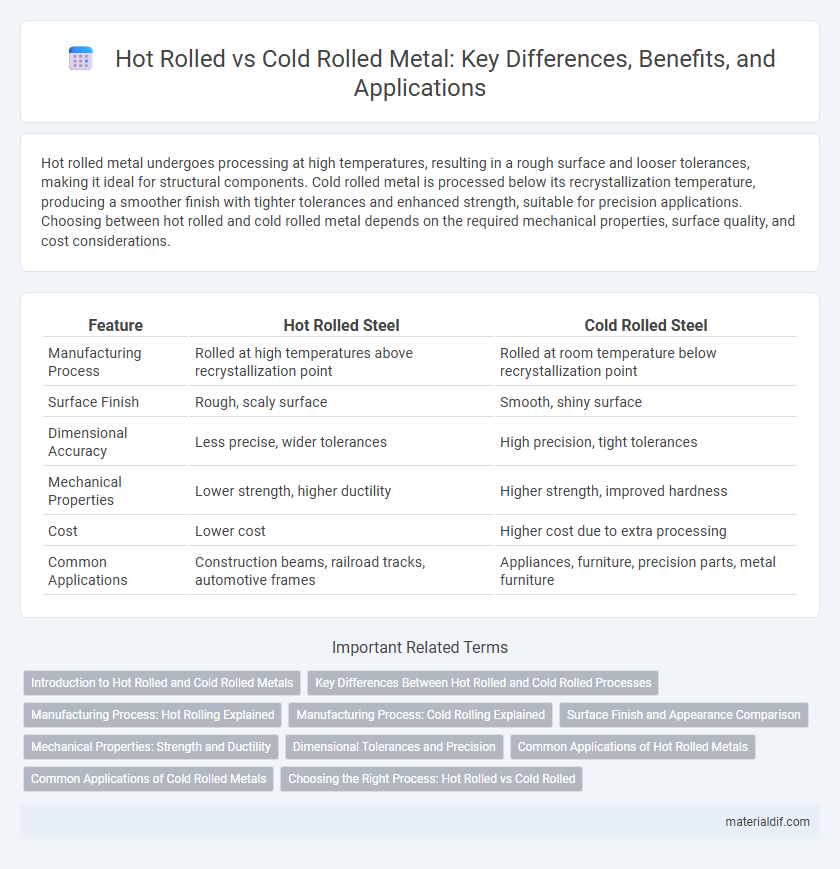

Table of Comparison

| Feature | Hot Rolled Steel | Cold Rolled Steel |

|---|---|---|

| Manufacturing Process | Rolled at high temperatures above recrystallization point | Rolled at room temperature below recrystallization point |

| Surface Finish | Rough, scaly surface | Smooth, shiny surface |

| Dimensional Accuracy | Less precise, wider tolerances | High precision, tight tolerances |

| Mechanical Properties | Lower strength, higher ductility | Higher strength, improved hardness |

| Cost | Lower cost | Higher cost due to extra processing |

| Common Applications | Construction beams, railroad tracks, automotive frames | Appliances, furniture, precision parts, metal furniture |

Introduction to Hot Rolled and Cold Rolled Metals

Hot rolled metals are processed at high temperatures, above the metal's recrystallization point, resulting in a rough surface finish and more ductile properties suitable for structural applications. Cold rolled metals undergo further processing at room temperature, producing a smoother surface with tighter tolerances and greater strength due to strain hardening. The choice between hot rolled and cold rolled metals depends on the required mechanical properties, surface finish, and specific industrial applications.

Key Differences Between Hot Rolled and Cold Rolled Processes

Hot rolled steel undergoes processing at high temperatures above its recrystallization point, resulting in a rough surface finish and less precise dimensions, while cold rolled steel is processed below the recrystallization temperature, offering a smoother finish and tighter tolerances. The hot rolling process enhances ductility and reduces internal stresses, making it suitable for structural applications, whereas cold rolling increases strength through strain hardening, ideal for applications requiring superior surface quality and dimensional accuracy. Differences in production cost and mechanical properties significantly influence the choice between hot rolled and cold rolled steel for industrial uses.

Manufacturing Process: Hot Rolling Explained

Hot rolled steel undergoes a manufacturing process where metal slabs are heated above their recrystallization temperature, typically around 1700degF (926degC), making the steel malleable and easier to shape. The heated slabs pass through large rollers that reduce thickness and form the desired shape, followed by cooling at ambient temperature. This process produces steel with a rough surface texture and slightly altered mechanical properties compared to cold rolled steel, which is processed at room temperature.

Manufacturing Process: Cold Rolling Explained

Cold rolling is a metalworking process where steel is passed through rollers at a temperature below its recrystallization point, typically at room temperature, to achieve precise dimensions and a superior surface finish. This process increases the metal's strength through strain hardening while improving its ductility and surface smoothness, making it ideal for applications requiring tight tolerances. Cold rolling involves multiple passes, including annealing between stages to relieve internal stresses and refine microstructure, enhancing mechanical properties and dimensional accuracy.

Surface Finish and Appearance Comparison

Hot rolled metal features a rough, scaled surface due to cooling at ambient temperatures, often exhibiting a matte, textured finish ideal for structural applications. Cold rolled metal undergoes further processing at room temperature, resulting in a smoother, shinier surface with tighter dimensional tolerances, making it preferred for aesthetic and precision-demanding uses. The difference in surface finish significantly impacts the visual appeal and suitability for paint or coating adherence in various manufacturing industries.

Mechanical Properties: Strength and Ductility

Hot rolled steel exhibits lower tensile strength but higher ductility due to its slower cooling process, which results in coarser grain structures. Cold rolled steel undergoes further processing at room temperature, increasing tensile strength and surface finish while reducing ductility because of strain hardening. Selecting between hot rolled and cold rolled steel depends on the balance required between strength and ductility for specific engineering applications.

Dimensional Tolerances and Precision

Hot rolled metals exhibit broader dimensional tolerances due to the high-temperature processing, leading to less precise thickness and shape variations. Cold rolled metals undergo further processing at room temperature, providing tighter dimensional tolerances and enhanced surface finish for precision applications. This precision in cold rolling ensures superior consistency in thickness, flatness, and mechanical properties, essential for industries requiring exact specifications.

Common Applications of Hot Rolled Metals

Hot rolled metals are widely used in construction, automotive manufacturing, and heavy machinery due to their enhanced ductility and cost-effectiveness. Structural components such as I-beams, railroad tracks, and pipelines leverage the toughness and formability of hot rolled steel. These metals are ideal for applications where precise dimensions are less critical, but strength and durability are essential.

Common Applications of Cold Rolled Metals

Cold rolled metals are widely used in automotive body panels, appliances, and furniture due to their superior surface finish and tighter dimensional tolerances. They are preferred in applications requiring high strength and precision, such as electronic enclosures and metal shelving. The enhanced mechanical properties of cold rolled steel make it ideal for manufacturing components that demand rigidity and aesthetic appeal.

Choosing the Right Process: Hot Rolled vs Cold Rolled

Hot rolled steel offers superior formability and is cost-effective for large structural components, while cold rolled steel provides enhanced surface finish and tighter dimensional tolerances suited for precision applications. Selecting between hot rolled and cold rolled steel depends on factors such as desired mechanical properties, surface quality, and application requirements. Understanding these differences ensures optimal performance in automotive parts, construction materials, or manufacturing processes.

Hot Rolled vs Cold Rolled Infographic

materialdif.com

materialdif.com