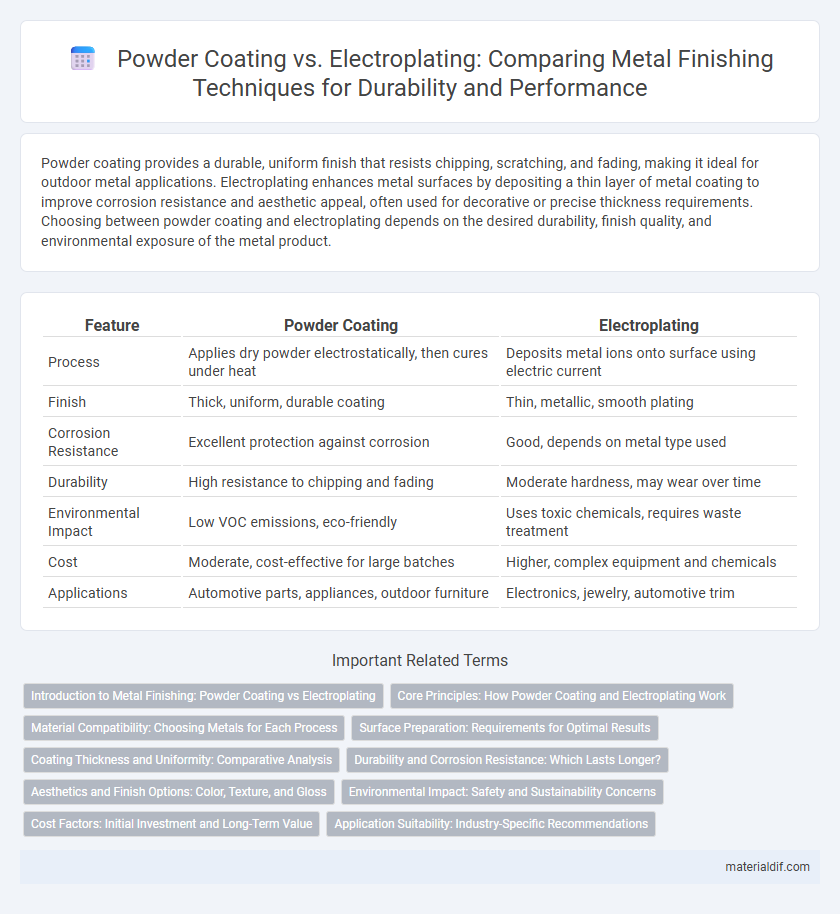

Powder coating provides a durable, uniform finish that resists chipping, scratching, and fading, making it ideal for outdoor metal applications. Electroplating enhances metal surfaces by depositing a thin layer of metal coating to improve corrosion resistance and aesthetic appeal, often used for decorative or precise thickness requirements. Choosing between powder coating and electroplating depends on the desired durability, finish quality, and environmental exposure of the metal product.

Table of Comparison

| Feature | Powder Coating | Electroplating |

|---|---|---|

| Process | Applies dry powder electrostatically, then cures under heat | Deposits metal ions onto surface using electric current |

| Finish | Thick, uniform, durable coating | Thin, metallic, smooth plating |

| Corrosion Resistance | Excellent protection against corrosion | Good, depends on metal type used |

| Durability | High resistance to chipping and fading | Moderate hardness, may wear over time |

| Environmental Impact | Low VOC emissions, eco-friendly | Uses toxic chemicals, requires waste treatment |

| Cost | Moderate, cost-effective for large batches | Higher, complex equipment and chemicals |

| Applications | Automotive parts, appliances, outdoor furniture | Electronics, jewelry, automotive trim |

Introduction to Metal Finishing: Powder Coating vs Electroplating

Powder coating and electroplating are prominent metal finishing techniques used to enhance durability and corrosion resistance. Powder coating applies a dry powder that is cured under heat to form a protective skin, while electroplating deposits a thin metal layer through an electrochemical process. Both methods improve surface aesthetics and longevity, but powder coating offers a thicker, more uniform finish, whereas electroplating provides superior conductivity and precision.

Core Principles: How Powder Coating and Electroplating Work

Powder coating involves applying a dry powder made of resin and pigment electrostatically onto metal surfaces, which is then cured under heat to form a durable, protective layer. Electroplating uses an electrical current to deposit a thin layer of metal, such as nickel or chromium, onto a conductive substrate, enhancing corrosion resistance and aesthetic appeal. Both processes improve metal durability, but powder coating provides a thicker, uniform coating while electroplating offers precise metal layering.

Material Compatibility: Choosing Metals for Each Process

Powder coating is highly compatible with aluminum, steel, and iron due to its ability to form a durable, uniform film on these substrates. Electroplating excels with metals like copper, nickel, and chromium, providing enhanced corrosion resistance and aesthetic finishes. Selecting the appropriate metal depends on the required surface properties and the compatibility of the metal with either powder coating or electroplating techniques.

Surface Preparation: Requirements for Optimal Results

Powder coating requires thorough surface cleaning to remove oils, dirt, and rust, often followed by abrasive blasting or chemical treatment to ensure optimal paint adhesion. Electroplating demands meticulous degreasing and acid pickling to eliminate contaminants and oxide layers for uniform metal deposition. Both processes depend on precise surface preparation to achieve durable, high-quality finishes and enhanced corrosion resistance.

Coating Thickness and Uniformity: Comparative Analysis

Powder coating typically results in a thicker, more uniform layer ranging from 50 to 150 microns, providing robust protection against corrosion and wear compared to electroplating, which generally offers thinner coatings around 5 to 25 microns. The uniformity of powder coating is enhanced by the electrostatic application process, ensuring consistent coverage even on complex geometries, whereas electroplating might exhibit variable thickness due to uneven current distribution. This makes powder coating a preferred choice for applications requiring durable, evenly coated metal surfaces.

Durability and Corrosion Resistance: Which Lasts Longer?

Powder coating offers superior corrosion resistance by creating a thick, durable layer that shields metal surfaces from moisture, chemicals, and UV exposure, preventing rust and degradation over time. Electroplating, while providing a thinner metal coating such as chromium or nickel, can be prone to chipping and wear, compromising its corrosion protection if the plating is damaged. For long-term durability in harsh environments, powder coating generally lasts longer due to its robust, impact-resistant finish and enhanced barrier properties against corrosion.

Aesthetics and Finish Options: Color, Texture, and Gloss

Powder coating offers a wide range of vibrant colors, customizable textures, and high-gloss finishes that enhance metal surfaces with durable, uniform coverage. Electroplating provides a sleek, metallic sheen with options for chrome, nickel, and gold finishes, delivering a smooth and reflective surface ideal for decorative and corrosion-resistant applications. Both methods enable tailored aesthetic outcomes, but powder coating excels in color variety and texture, while electroplating is preferred for achieving classic metallic lusters.

Environmental Impact: Safety and Sustainability Concerns

Powder coating offers a more environmentally friendly alternative to electroplating by producing minimal hazardous waste and eliminating the use of toxic chemicals like chromium and cyanide commonly found in electroplating processes. Electroplating generates significant chemical runoff, requiring extensive treatment to prevent soil and water contamination, which poses safety risks to workers and surrounding ecosystems. Powder coating's low VOC emissions and recyclable overspray contribute to its sustainability, making it a safer choice for metal finishing industries aiming to reduce environmental impact.

Cost Factors: Initial Investment and Long-Term Value

Powder coating typically requires a lower initial investment compared to electroplating, as it involves simpler equipment and fewer chemicals, reducing upfront costs. Electroplating demands higher capital for plating baths, rectifiers, and wastewater treatment systems but offers superior corrosion resistance and finish durability that can enhance long-term value. Considering maintenance expenses and environmental compliance, powder coating often provides cost-effective benefits for large-scale metal finishing with faster turnaround times.

Application Suitability: Industry-Specific Recommendations

Powder coating is ideal for automotive, appliances, and outdoor furniture industries due to its durability, corrosion resistance, and environmental friendliness. Electroplating suits electronics, aerospace, and jewelry sectors where precise, thin metal layers enhance conductivity and aesthetic appeal. Choosing between these methods depends on specific industry needs, balancing protection, appearance, and technical performance.

Powder Coating vs Electroplating Infographic

materialdif.com

materialdif.com