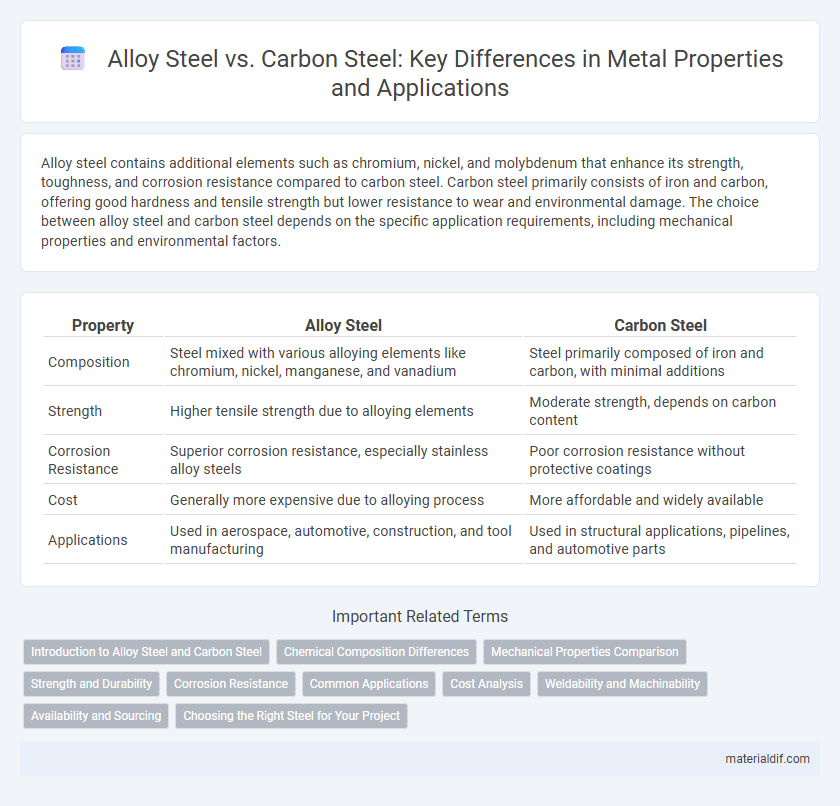

Alloy steel contains additional elements such as chromium, nickel, and molybdenum that enhance its strength, toughness, and corrosion resistance compared to carbon steel. Carbon steel primarily consists of iron and carbon, offering good hardness and tensile strength but lower resistance to wear and environmental damage. The choice between alloy steel and carbon steel depends on the specific application requirements, including mechanical properties and environmental factors.

Table of Comparison

| Property | Alloy Steel | Carbon Steel |

|---|---|---|

| Composition | Steel mixed with various alloying elements like chromium, nickel, manganese, and vanadium | Steel primarily composed of iron and carbon, with minimal additions |

| Strength | Higher tensile strength due to alloying elements | Moderate strength, depends on carbon content |

| Corrosion Resistance | Superior corrosion resistance, especially stainless alloy steels | Poor corrosion resistance without protective coatings |

| Cost | Generally more expensive due to alloying process | More affordable and widely available |

| Applications | Used in aerospace, automotive, construction, and tool manufacturing | Used in structural applications, pipelines, and automotive parts |

Introduction to Alloy Steel and Carbon Steel

Alloy steel contains additional elements such as chromium, nickel, and molybdenum to enhance properties like strength, corrosion resistance, and toughness, making it suitable for specialized applications. Carbon steel primarily consists of iron and carbon, with varying carbon content to influence hardness, ductility, and tensile strength, commonly used in construction and manufacturing. Understanding the composition differences between alloy steel and carbon steel is essential for selecting the appropriate material based on performance requirements.

Chemical Composition Differences

Alloy steel contains various alloying elements such as chromium, nickel, molybdenum, and vanadium, which enhance properties like strength, hardness, and corrosion resistance, while carbon steel primarily consists of iron and carbon, with carbon content typically ranging from 0.02% to 2.1%. The presence of alloying elements in alloy steel enables customized mechanical properties and improved performance in harsh environments, whereas carbon steel's composition leads to more straightforward processing and generally lower cost. The difference in chemical composition significantly impacts the steel's applications, durability, and resistance to wear and oxidation.

Mechanical Properties Comparison

Alloy steel exhibits superior mechanical properties compared to carbon steel, such as enhanced tensile strength, hardness, and toughness due to the addition of elements like chromium, nickel, and molybdenum. Carbon steel offers higher strength and hardness with increased carbon content but tends to be less ductile and more prone to brittleness. The improved wear resistance and corrosion resistance of alloy steel make it ideal for applications requiring durability under extreme conditions.

Strength and Durability

Alloy steel exhibits superior strength and durability compared to carbon steel due to the presence of elements like chromium, nickel, and molybdenum, which enhance hardness and resistance to wear and corrosion. Carbon steel, primarily composed of iron and carbon, offers adequate strength but is more susceptible to rust and wear over time, making it less durable under harsh conditions. The enhanced mechanical properties of alloy steel make it ideal for heavy-duty applications requiring long-lasting materials.

Corrosion Resistance

Alloy steel exhibits superior corrosion resistance compared to carbon steel due to the inclusion of elements like chromium, nickel, and molybdenum, which create a protective oxide layer on the surface. Carbon steel lacks these alloying elements, making it more prone to rust and degradation when exposed to moisture and chemicals. Stainless steel, a variant of alloy steel, offers exceptional resistance in harsh environments, making it ideal for applications requiring durability against corrosion.

Common Applications

Alloy steel finds common applications in aerospace, automotive, and power generation industries due to its enhanced strength, toughness, and resistance to corrosion and wear. Carbon steel is widely used in construction, pipelines, and manufacturing of tools and machinery because of its high tensile strength and cost-effectiveness. Both steels serve distinct roles where alloy steel excels in high-performance environments while carbon steel dominates in structural and general-purpose applications.

Cost Analysis

Alloy steel typically incurs higher production costs than carbon steel due to the inclusion of alloying elements such as chromium, nickel, and molybdenum, which enhance mechanical properties and corrosion resistance. Carbon steel offers a more cost-effective solution for applications where high strength and toughness are required without specialized properties. The initial investment and processing expenses for alloy steel often justify their use in critical environments, whereas carbon steel remains preferable for budget-sensitive structural components.

Weldability and Machinability

Alloy steel generally exhibits lower weldability compared to carbon steel due to the presence of additional alloying elements which can cause cracking or require preheating during welding. Machinability of carbon steel is often higher, especially in low to medium carbon grades, because its simpler composition allows for easier cutting and shaping. Welding alloy steel demands precise control of heat input and appropriate filler materials to maintain strength and avoid defects.

Availability and Sourcing

Alloy steel and carbon steel differ significantly in availability and sourcing due to their material compositions and production processes. Carbon steel, widely produced and used globally, offers easy sourcing and higher availability in standard grades and forms, making it a cost-effective choice for many industries. Alloy steel, containing added elements such as chromium, nickel, or molybdenum, has more specialized production requirements, resulting in limited availability and higher sourcing costs, particularly for high-performance or corrosion-resistant grades.

Choosing the Right Steel for Your Project

Alloy steel offers enhanced strength, toughness, and resistance to corrosion and wear compared to carbon steel, making it ideal for demanding applications like aerospace, automotive, and heavy machinery. Carbon steel provides excellent hardness and affordability, suitable for construction, structural components, and general-purpose tools where high tensile strength is required. Selecting the right steel depends on project-specific factors such as mechanical properties, environmental exposure, and budget constraints to ensure optimal performance and cost-efficiency.

Alloy Steel vs Carbon Steel Infographic

materialdif.com

materialdif.com