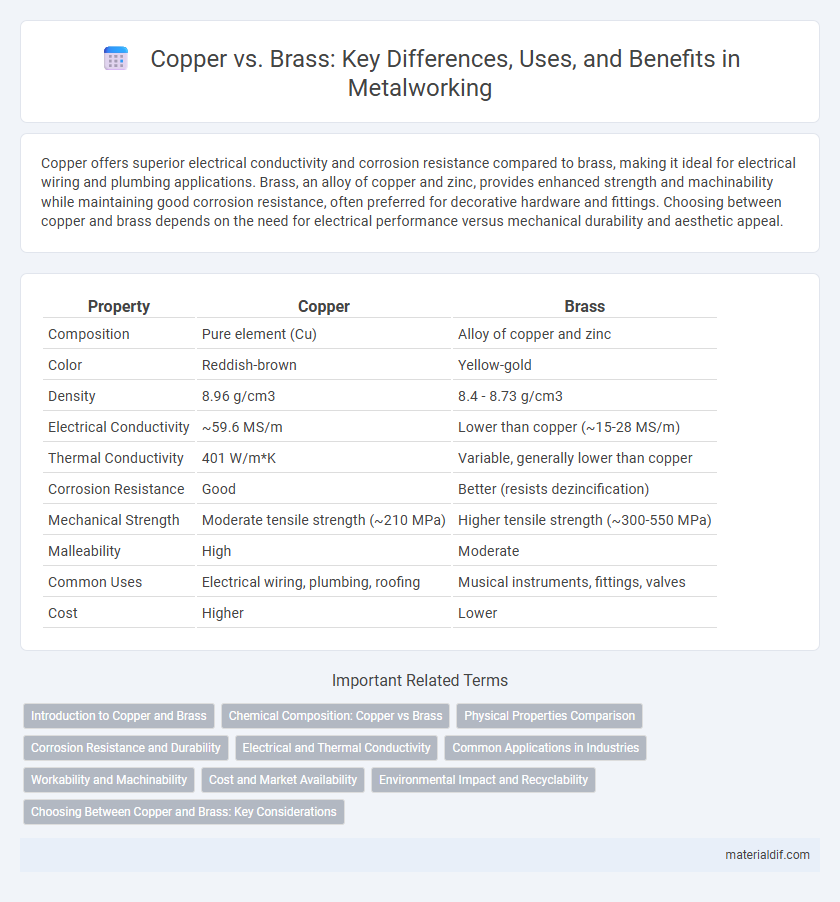

Copper offers superior electrical conductivity and corrosion resistance compared to brass, making it ideal for electrical wiring and plumbing applications. Brass, an alloy of copper and zinc, provides enhanced strength and machinability while maintaining good corrosion resistance, often preferred for decorative hardware and fittings. Choosing between copper and brass depends on the need for electrical performance versus mechanical durability and aesthetic appeal.

Table of Comparison

| Property | Copper | Brass |

|---|---|---|

| Composition | Pure element (Cu) | Alloy of copper and zinc |

| Color | Reddish-brown | Yellow-gold |

| Density | 8.96 g/cm3 | 8.4 - 8.73 g/cm3 |

| Electrical Conductivity | ~59.6 MS/m | Lower than copper (~15-28 MS/m) |

| Thermal Conductivity | 401 W/m*K | Variable, generally lower than copper |

| Corrosion Resistance | Good | Better (resists dezincification) |

| Mechanical Strength | Moderate tensile strength (~210 MPa) | Higher tensile strength (~300-550 MPa) |

| Malleability | High | Moderate |

| Common Uses | Electrical wiring, plumbing, roofing | Musical instruments, fittings, valves |

| Cost | Higher | Lower |

Introduction to Copper and Brass

Copper is a reddish-orange metal known for its high electrical conductivity, corrosion resistance, and malleability, commonly used in electrical wiring and plumbing. Brass is an alloy primarily composed of copper and zinc, valued for its durability, acoustic properties, and resistance to tarnishing, frequently utilized in musical instruments and decorative hardware. Understanding the distinct compositions and properties of copper and brass is essential for selecting the appropriate material in industrial and artistic applications.

Chemical Composition: Copper vs Brass

Copper is a pure metal with the chemical symbol Cu and an atomic number of 29, known for its excellent electrical conductivity and corrosion resistance. Brass is an alloy primarily composed of copper and zinc, with zinc content typically ranging from 5% to 40%, which alters its mechanical properties and enhances its strength and machinability. The presence of zinc in brass reduces copper's ductility and electrical conductivity but increases its hardness and resistance to tarnishing.

Physical Properties Comparison

Copper exhibits higher electrical conductivity and thermal conductivity compared to brass, making it ideal for electrical wiring and heat exchange applications. Brass, an alloy of copper and zinc, possesses superior hardness and corrosion resistance, enhancing its durability in mechanical and marine environments. The density of copper is approximately 8.96 g/cm3, whereas brass typically ranges from 8.4 to 8.7 g/cm3, contributing to differences in weight and strength between the two metals.

Corrosion Resistance and Durability

Copper exhibits superior corrosion resistance due to its natural patina formation that protects against environmental damage, making it ideal for outdoor and marine applications. Brass, an alloy of copper and zinc, offers enhanced durability and strength but is more susceptible to dezincification corrosion when exposed to certain water conditions. Both metals provide valuable corrosion resistance, yet copper's longevity in harsh environments outperforms brass in durability over time.

Electrical and Thermal Conductivity

Copper exhibits superior electrical and thermal conductivity compared to brass, making it the preferred choice for electrical wiring and heat exchangers. Brass, an alloy of copper and zinc, has reduced conductivity due to the presence of zinc, which disrupts electron flow and heat transfer. This difference results in copper having approximately 97% of the IACS electrical conductivity rating, while brass typically ranges from 15% to 28%, impacting their performance in electrical and thermal applications.

Common Applications in Industries

Copper is widely used in electrical wiring, plumbing, and electronics due to its excellent conductivity and corrosion resistance. Brass, an alloy of copper and zinc, is favored in manufacturing musical instruments, fittings, and decorative hardware because of its durability and attractive gold-like appearance. Both metals find significant applications in the automotive and construction industries, but copper's superior thermal and electrical properties make it essential for electrical components, while brass is preferred for mechanical parts requiring low friction and high machinability.

Workability and Machinability

Copper exhibits excellent workability due to its high ductility and malleability, allowing it to be easily shaped and formed without cracking. Brass, an alloy of copper and zinc, offers superior machinability compared to pure copper, making it ideal for precision machining processes such as milling and turning. The enhanced machinability of brass results from its lower tendency to work-harden, reducing tool wear and improving production efficiency.

Cost and Market Availability

Copper generally commands a higher price in the metal market due to its superior electrical conductivity and widespread industrial applications, making it more costly than brass. Brass, an alloy of copper and zinc, offers a more affordable alternative with good corrosion resistance and machinability, leading to broader availability in consumer goods and decorative items. Market availability of copper can be influenced by global mining outputs and industrial demand, while brass is more readily accessible due to its manufactured nature and versatile uses.

Environmental Impact and Recyclability

Copper mining generates significant environmental impacts, including habitat disruption and energy-intensive extraction processes, while copper is highly recyclable with up to 90% efficiency, reducing the need for virgin ore. Brass, an alloy primarily of copper and zinc, shares copper's recyclability benefits but involves additional energy and resources in alloying and refining, impacting its overall environmental footprint. Recycling brass conserves metal resources and lowers greenhouse gas emissions, making both metals sustainable choices compared to virgin production when recycled properly.

Choosing Between Copper and Brass: Key Considerations

Choosing between copper and brass requires evaluating factors such as corrosion resistance, conductivity, and appearance. Copper offers superior electrical and thermal conductivity, making it ideal for wiring and heat exchangers, while brass, an alloy of copper and zinc, provides enhanced strength and machinability suitable for decorative and mechanical applications. Cost and environmental resistance also influence the decision, with brass being more cost-effective and resistant to tarnishing compared to pure copper.

Copper vs Brass Infographic

materialdif.com

materialdif.com