Annealing involves heating metal to a specific temperature and then cooling it slowly to reduce hardness and increase ductility, enhancing its workability. Quenching rapidly cools heated metal, typically in water or oil, to increase hardness and strength by trapping carbon atoms in a hardened microstructure. Understanding the differences between annealing and quenching is crucial for selecting the appropriate heat treatment to achieve desired mechanical properties in metalworking.

Table of Comparison

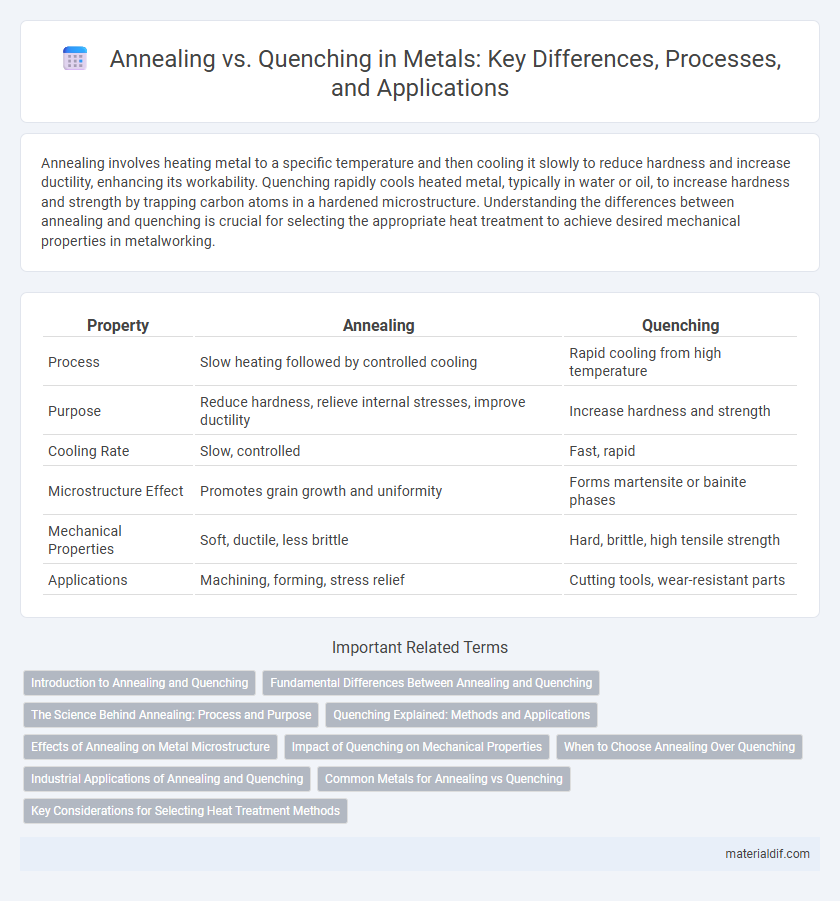

| Property | Annealing | Quenching |

|---|---|---|

| Process | Slow heating followed by controlled cooling | Rapid cooling from high temperature |

| Purpose | Reduce hardness, relieve internal stresses, improve ductility | Increase hardness and strength |

| Cooling Rate | Slow, controlled | Fast, rapid |

| Microstructure Effect | Promotes grain growth and uniformity | Forms martensite or bainite phases |

| Mechanical Properties | Soft, ductile, less brittle | Hard, brittle, high tensile strength |

| Applications | Machining, forming, stress relief | Cutting tools, wear-resistant parts |

Introduction to Annealing and Quenching

Annealing is a heat treatment process that involves heating metal to a specific temperature and then slowly cooling it to soften the material and improve its ductility. Quenching rapidly cools the heated metal, typically in water or oil, resulting in increased hardness and strength but reduced ductility. Both processes are critical in controlling the microstructure and mechanical properties of metals for various industrial applications.

Fundamental Differences Between Annealing and Quenching

Annealing involves heating a metal to a specific temperature and then cooling it slowly to reduce hardness and improve ductility by allowing atomic structures to reorganize. Quenching rapidly cools the metal, typically in water or oil, to increase hardness and strength by locking atoms in a non-equilibrium state. The fundamental difference lies in the cooling rate, with annealing promoting softness and ductility and quenching producing hardness and brittleness.

The Science Behind Annealing: Process and Purpose

Annealing involves heating metal to a specific temperature below its melting point, followed by slow cooling to alter its microstructure, relieve internal stresses, and improve ductility. This controlled process refines the grain structure, enhancing mechanical properties and making metals more workable for subsequent manufacturing processes. The scientific principle relies on diffusion and recrystallization mechanisms that restore metal's softness and reduce brittleness caused by prior cold working.

Quenching Explained: Methods and Applications

Quenching is a rapid cooling process used in metalworking to alter the microstructure and increase hardness by transforming austenite into martensite. Common quenching methods include water quenching, oil quenching, and air quenching, each selected based on the metal type and desired mechanical properties. Applications of quenching are critical in automotive, aerospace, and tool manufacturing industries to enhance wear resistance and strength.

Effects of Annealing on Metal Microstructure

Annealing refines metal microstructure by reducing dislocations and promoting recrystallization, resulting in improved ductility and reduced hardness. The process allows grain growth, creating a more uniform grain size that enhances toughness and machinability. By relieving internal stresses, annealing also stabilizes the metal's dimensional properties and reduces the risk of cracking during subsequent processing.

Impact of Quenching on Mechanical Properties

Quenching significantly increases the hardness and strength of metal by rapidly cooling it from a high temperature, which forms a martensitic microstructure. This rapid cooling reduces ductility and toughness, making the metal more brittle compared to annealed counterparts. Quenched metals are ideal for applications requiring high wear resistance and strength but may require tempering to balance hardness and reduce brittleness.

When to Choose Annealing Over Quenching

Annealing is preferred when the goal is to soften metal, relieve internal stresses, and improve ductility for further machining or shaping processes. It is ideal for metals that require uniform grain structure and enhanced toughness rather than maximum hardness. Selecting annealing over quenching is essential when avoiding brittleness and ensuring better machinability in steel alloys.

Industrial Applications of Annealing and Quenching

Annealing is widely used in industrial applications to soften metals, improve ductility, and relieve internal stresses, enhancing the machinability of steel and aluminum components in automotive and aerospace manufacturing. Quenching, on the other hand, is employed to rapidly cool metals from high temperatures, increasing hardness and strength, which is crucial in producing wear-resistant tools, gears, and structural parts in heavy machinery and tool-making industries. Both processes are integral in tailoring metal properties to meet specific performance requirements in various industrial sectors.

Common Metals for Annealing vs Quenching

Common metals subjected to annealing include copper, steel, and aluminum, which undergo controlled heating and slow cooling to enhance ductility and reduce hardness. Quenching is frequently applied to carbon steels and tool steels to rapidly cool the metal, increasing hardness and strength but reducing malleability. Annealing optimizes metals like copper alloys and low-carbon steel for forming processes, whereas quenching is preferred for high-carbon steels requiring superior wear resistance.

Key Considerations for Selecting Heat Treatment Methods

Selecting between annealing and quenching depends on the desired mechanical properties and material composition of the metal. Annealing is ideal for reducing hardness, increasing ductility, and relieving internal stresses, making it suitable for forming processes and welded structures. Quenching rapidly cools the metal to increase hardness and strength, but it requires careful control of cooling rates and subsequent tempering to prevent brittleness and cracking.

Annealing vs Quenching Infographic

materialdif.com

materialdif.com