Powder coating provides a durable, corrosion-resistant finish by applying a dry powder that is cured under heat, offering a thicker and more uniform coating compared to metal plating. Metal plating involves depositing a thin layer of metal onto a surface through electroplating or other chemical processes, enhancing conductivity and aesthetic appeal but potentially wearing thinner over time. Choosing between powder coating and metal plating depends on the required durability, environmental resistance, and visual finish for the metal application.

Table of Comparison

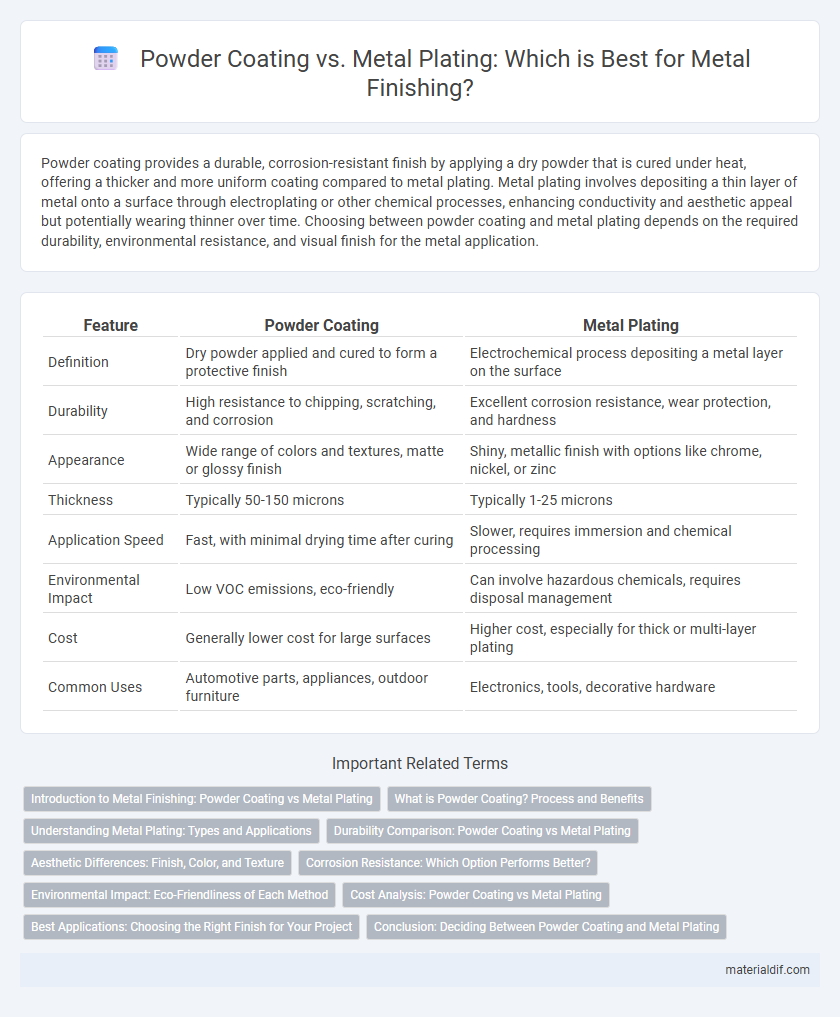

| Feature | Powder Coating | Metal Plating |

|---|---|---|

| Definition | Dry powder applied and cured to form a protective finish | Electrochemical process depositing a metal layer on the surface |

| Durability | High resistance to chipping, scratching, and corrosion | Excellent corrosion resistance, wear protection, and hardness |

| Appearance | Wide range of colors and textures, matte or glossy finish | Shiny, metallic finish with options like chrome, nickel, or zinc |

| Thickness | Typically 50-150 microns | Typically 1-25 microns |

| Application Speed | Fast, with minimal drying time after curing | Slower, requires immersion and chemical processing |

| Environmental Impact | Low VOC emissions, eco-friendly | Can involve hazardous chemicals, requires disposal management |

| Cost | Generally lower cost for large surfaces | Higher cost, especially for thick or multi-layer plating |

| Common Uses | Automotive parts, appliances, outdoor furniture | Electronics, tools, decorative hardware |

Introduction to Metal Finishing: Powder Coating vs Metal Plating

Powder coating and metal plating are two principal metal finishing techniques that enhance durability, corrosion resistance, and aesthetic appeal. Powder coating uses a dry powder cured under heat to form a protective layer, offering environmental benefits and superior impact resistance. Metal plating involves depositing a fine metal layer through electrochemical or mechanical processes, providing excellent conductivity, hardness, and wear resistance.

What is Powder Coating? Process and Benefits

Powder coating is a dry finishing process where finely ground particles of pigment and resin are electrostatically charged and sprayed onto a metal surface, then cured under heat to form a durable, protective layer. This method provides a uniform, corrosion-resistant coating that enhances metal durability and aesthetics, reducing chipping, scratching, and fading compared to traditional paint. Benefits include environmental friendliness due to the absence of solvents, improved impact resistance, and a wide variety of color and texture options suitable for industrial and commercial metal applications.

Understanding Metal Plating: Types and Applications

Metal plating involves depositing a thin layer of metal onto a substrate to enhance corrosion resistance, aesthetics, and conductivity. Common plating types include electroplating, electroless plating, and immersion plating, each suited for specific applications such as automotive, electronics, and jewelry manufacturing. Understanding the differences in plating processes helps determine optimal surface protection based on factors like durability, environmental exposure, and desired finish quality.

Durability Comparison: Powder Coating vs Metal Plating

Powder coating offers excellent durability with strong resistance to chipping, scratching, and fading, making it ideal for outdoor and industrial applications. Metal plating provides a harder surface layer with superior corrosion resistance and wear protection, often extending the lifespan of metal components in harsh environments. While powder coating excels in impact resistance and UV stability, metal plating generally outperforms in chemical resistance and long-term endurance under heavy mechanical stress.

Aesthetic Differences: Finish, Color, and Texture

Powder coating offers a smooth, uniform finish with vibrant color options and a matte to semi-gloss texture, providing enhanced durability and resistance to chipping or fading. Metal plating delivers a shiny, reflective surface in metallic hues such as chrome, nickel, or gold, often with a polished or brushed texture that highlights the metal's natural luster. Differences in aesthetic appeal depend on whether the preference is for bold color variety and texture uniformity in powder coating or the classic metallic sheen and smoothness of metal plating.

Corrosion Resistance: Which Option Performs Better?

Powder coating provides a durable, thick protective layer that resists corrosion by creating a barrier against moisture and chemicals, making it highly effective for outdoor and industrial applications. Metal plating, such as zinc or chrome plating, offers excellent corrosion resistance by chemically bonding to the metal surface and adding a protective metallic layer that inhibits oxidation. The choice between powder coating and metal plating depends on environmental exposure, with metal plating excelling in harsh, saline environments and powder coating preferred for impact-resistant, decorative finishes.

Environmental Impact: Eco-Friendliness of Each Method

Powder coating significantly reduces volatile organic compound (VOC) emissions compared to traditional metal plating, making it a more eco-friendly choice. Metal plating often involves toxic chemicals and heavy metals like chromium and cadmium that can contaminate water and soil if not properly managed. Powder coating uses fewer hazardous substances and generates less hazardous waste, contributing to a lower environmental footprint in metal finishing processes.

Cost Analysis: Powder Coating vs Metal Plating

Powder coating offers a cost-effective solution for metal finishing, typically reducing expenses by 20-40% compared to metal plating due to lower material and labor costs. Metal plating involves higher initial investment in equipment and chemicals, with ongoing maintenance costs driving up overall expenses. While powder coating excels in affordability and durability for large projects, metal plating may incur greater costs but provides superior corrosion resistance and aesthetic precision for high-end applications.

Best Applications: Choosing the Right Finish for Your Project

Powder coating provides a durable, corrosion-resistant finish ideal for outdoor furniture, automotive parts, and architectural structures exposed to harsh weather. Metal plating, such as chrome or nickel plating, offers superior wear resistance and conductivity, making it perfect for electronic components, tools, and decorative hardware. Selecting the right finish depends on the project's requirements for aesthetic appeal, environmental exposure, and functional performance.

Conclusion: Deciding Between Powder Coating and Metal Plating

Powder coating offers superior corrosion resistance and environmental benefits due to its non-toxic, solvent-free formulation, making it ideal for outdoor applications and large metal surfaces. Metal plating provides a thinner, more conductive finish with enhanced wear resistance, suitable for precision components requiring electrical conductivity or decorative appeal. The final choice depends on factors like durability requirements, aesthetic preferences, cost efficiency, and specific application environments.

Powder Coating vs Metal Plating Infographic

materialdif.com

materialdif.com