Formability refers to a metal's ability to undergo deformation without cracking, making it ideal for processes like rolling, bending, and forging. Machinability measures how easily a metal can be cut or shaped using machining tools, affecting tool wear, surface finish, and machining speed. Metals with high formability often exhibit lower machinability due to their ductile nature, while harder metals may offer better machinability but reduced formability.

Table of Comparison

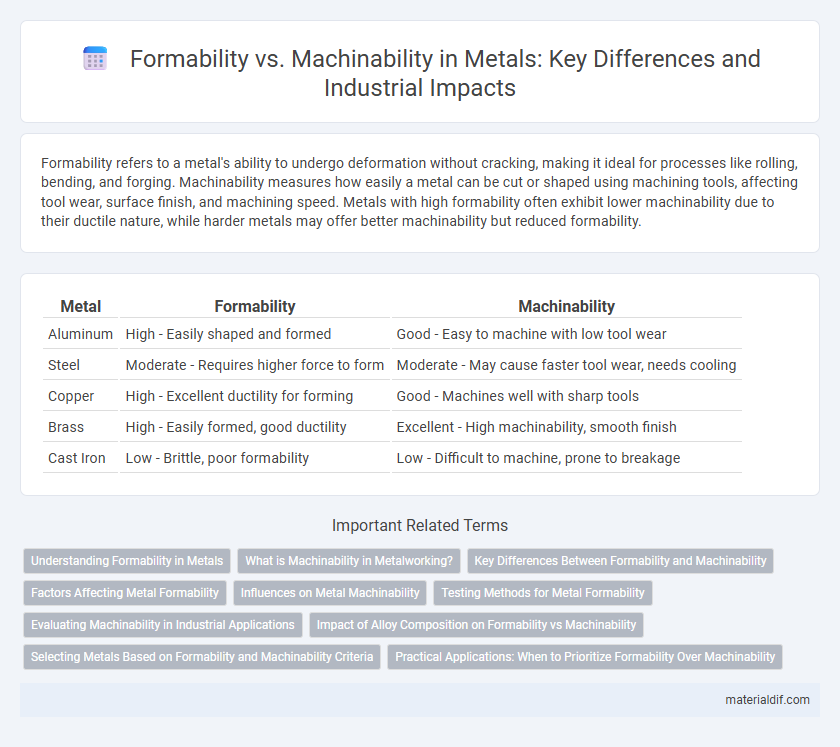

| Metal | Formability | Machinability |

|---|---|---|

| Aluminum | High - Easily shaped and formed | Good - Easy to machine with low tool wear |

| Steel | Moderate - Requires higher force to form | Moderate - May cause faster tool wear, needs cooling |

| Copper | High - Excellent ductility for forming | Good - Machines well with sharp tools |

| Brass | High - Easily formed, good ductility | Excellent - High machinability, smooth finish |

| Cast Iron | Low - Brittle, poor formability | Low - Difficult to machine, prone to breakage |

Understanding Formability in Metals

Formability in metals refers to the ability of a metal to undergo plastic deformation without cracking during manufacturing processes such as stamping, bending, or deep drawing. High formability metals, like aluminum alloys and low-carbon steels, exhibit excellent ductility and strain-hardening capacity, enabling complex shapes with minimal defects. Understanding formability is crucial for optimizing metal selection and process parameters to achieve desired product geometry and performance.

What is Machinability in Metalworking?

Machinability in metalworking refers to the ease with which a metal can be cut, shaped, or finished using machining tools, directly impacting tool life, surface finish, and production efficiency. Metals with high machinability produce less tool wear, require lower cutting forces, and generate smoother surfaces, making them ideal for precision components and high-volume manufacturing. Factors influencing machinability include metal composition, hardness, microstructure, and thermal conductivity, which determine cutting speed, feed rate, and tool material selection.

Key Differences Between Formability and Machinability

Formability refers to the ability of metal to undergo plastic deformation without cracking during processes like bending, drawing, or rolling, while machinability measures how easily metal can be cut, shaped, or finished using machining tools. Key differences include that formability depends largely on metal ductility and strain hardening, whereas machinability relies on factors like hardness, thermal conductivity, and tool wear resistance. Understanding these distinctions is crucial for selecting metals in manufacturing processes where either shaping or precise machining is prioritized.

Factors Affecting Metal Formability

Metal formability is primarily influenced by factors such as grain size, temperature, strain rate, and alloy composition, which determine the metal's ability to undergo plastic deformation without fracture. Higher temperatures generally enhance formability by increasing ductility, while fine grain sizes improve metal strength and drawability. Alloying elements and heat treatment processes also significantly affect the metal's microstructure, thereby impacting its formability characteristics.

Influences on Metal Machinability

Metal machinability is influenced by factors such as alloy composition, heat treatment, and microstructure, which determine cutting forces, tool wear, and surface finish quality. High formability metals typically have lower strength and hardness, resulting in easier deformation but potential challenges in maintaining dimensional accuracy during machining. Understanding the balance between formability and machinability is crucial for selecting appropriate materials and optimizing manufacturing processes in metalworking industries.

Testing Methods for Metal Formability

Testing methods for metal formability include tensile testing, bend testing, and Nakajima dome testing, each designed to evaluate different deformation characteristics. Tensile tests measure ductility and ultimate tensile strength, while bend tests assess flexibility and resistance to cracking under bending forces. Nakajima dome testing provides detailed information on strain distribution and sheet metal thinning, critical for understanding material behavior during forming processes.

Evaluating Machinability in Industrial Applications

Evaluating machinability in industrial applications involves assessing factors such as cutting speed, tool wear, and surface finish quality of metals like steel, aluminum, and titanium alloys. High machinability metals reduce production time and tool costs by enabling faster cutting rates and longer tool life. Understanding the balance between formability and machinability is crucial for selecting materials that meet specific manufacturing requirements while optimizing operational efficiency.

Impact of Alloy Composition on Formability vs Machinability

Alloy composition significantly affects the formability and machinability of metals by altering their microstructure and mechanical properties. High levels of alloying elements such as carbon, chromium, and nickel typically enhance strength and wear resistance but reduce formability due to increased hardness and decreased ductility. Conversely, alloys with lower concentrations of these elements tend to exhibit improved formability but may compromise machinability by causing excessive tool wear or poor surface finish.

Selecting Metals Based on Formability and Machinability Criteria

Selecting metals based on formability and machinability requires evaluating the alloy's ductility, hardness, and thermal conductivity to ensure suitability for manufacturing processes. High formability metals like aluminum and low carbon steel support complex shaping without cracking, while metals with superior machinability such as free-machining brass and certain grades of stainless steel exhibit efficient cutting and minimal tool wear. Balancing these criteria optimizes production efficiency, reduces costs, and ensures component performance.

Practical Applications: When to Prioritize Formability Over Machinability

In industries such as automotive and aerospace manufacturing, prioritizing formability over machinability is essential when creating complex shapes or components that require deep drawing, bending, or stretching without cracking. Sheet metals like aluminum and mild steel are favored for their high formability, enabling efficient production of intricate parts through stamping or pressing processes. When component geometry demands flexibility and minimal post-processing, selecting metals with superior formability reduces tooling costs and improves material utilization compared to machining-focused approaches.

Formability vs Machinability Infographic

materialdif.com

materialdif.com