Extrusion shapes metal by forcing it through a die, producing uniform cross-sections ideal for complex profiles and lightweight structures, while forging involves compressive forces that enhance metal grain flow, resulting in superior strength and durability. Extrusion excels in creating intricate shapes with consistent dimensions, making it cost-effective for high-volume production. Forging is preferred for components subjected to high stress, offering enhanced mechanical properties and fatigue resistance.

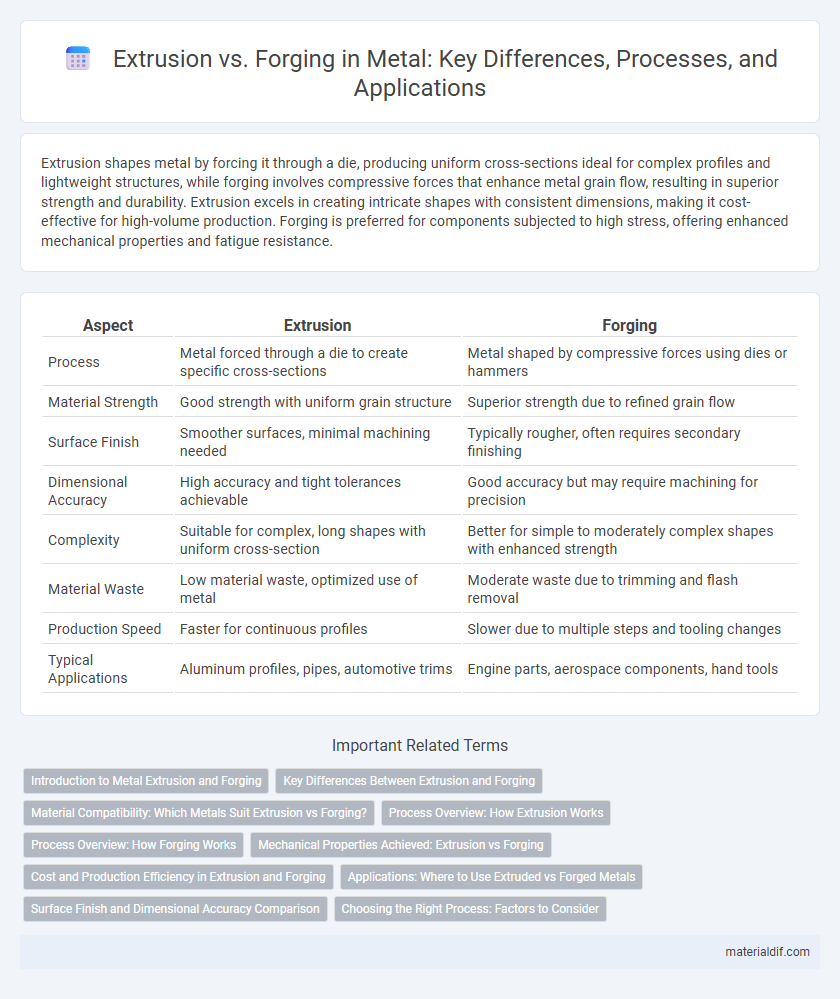

Table of Comparison

| Aspect | Extrusion | Forging |

|---|---|---|

| Process | Metal forced through a die to create specific cross-sections | Metal shaped by compressive forces using dies or hammers |

| Material Strength | Good strength with uniform grain structure | Superior strength due to refined grain flow |

| Surface Finish | Smoother surfaces, minimal machining needed | Typically rougher, often requires secondary finishing |

| Dimensional Accuracy | High accuracy and tight tolerances achievable | Good accuracy but may require machining for precision |

| Complexity | Suitable for complex, long shapes with uniform cross-section | Better for simple to moderately complex shapes with enhanced strength |

| Material Waste | Low material waste, optimized use of metal | Moderate waste due to trimming and flash removal |

| Production Speed | Faster for continuous profiles | Slower due to multiple steps and tooling changes |

| Typical Applications | Aluminum profiles, pipes, automotive trims | Engine parts, aerospace components, hand tools |

Introduction to Metal Extrusion and Forging

Metal extrusion involves forcing heated metal through a die to create objects with a fixed cross-sectional profile, enabling precise shapes with uniform thickness. Forging reshapes metal by applying compressive forces, enhancing its mechanical properties and grain structure for superior strength. Both processes serve distinct manufacturing purposes, with extrusion favoring complex, continuous shapes and forging producing robust, high-integrity components.

Key Differences Between Extrusion and Forging

Extrusion involves forcing metal through a die to create long objects with consistent cross-sections, while forging shapes metal using compressive forces often applied with a hammer or press. Extrusion provides precise control over complex shapes and is ideal for creating uniform profiles, whereas forging enhances the metal's mechanical properties by refining its grain structure. The key differences lie in the manufacturing process, shape complexity, and strength improvement capabilities.

Material Compatibility: Which Metals Suit Extrusion vs Forging?

Aluminum, copper, and magnesium alloys are highly compatible with extrusion due to their excellent ductility and ability to maintain strength during the process. Steel, titanium, and high-strength alloys are better suited for forging because they can withstand significant deformation and develop superior mechanical properties under compressive forces. Selecting the appropriate metal depends on the desired product characteristics, such as strength, shape complexity, and production volume.

Process Overview: How Extrusion Works

Extrusion involves forcing heated metal through a shaped die to create continuous profiles with consistent cross-sections, ideal for rods, tubes, and complex shapes. This process offers precise control over dimensions and surface finish, enhancing material properties by aligning grain flow along the extrusion direction. Unlike forging, extrusion achieves complex geometries with minimal waste and higher production speeds.

Process Overview: How Forging Works

Forging involves shaping metal by applying compressive forces using a hammer or press, which refines the metal's grain structure and enhances its mechanical properties. This process typically includes heating the metal to a plastic state before deformation, enabling improved strength, toughness, and resistance to fatigue compared to extrusion. Forged components exhibit superior structural integrity due to the directional grain flow aligned with the part geometry, making forging ideal for critical applications in aerospace, automotive, and heavy machinery industries.

Mechanical Properties Achieved: Extrusion vs Forging

Extrusion produces metals with uniform mechanical properties and enhanced tensile strength due to the continuous grain flow along the extruded profile. Forging results in superior mechanical properties, such as increased fatigue resistance and toughness, by refining the grain structure through controlled deformation and directional grain flow. While extrusion provides consistent ductility and dimensional accuracy, forging typically achieves higher impact strength and overall durability in critical applications.

Cost and Production Efficiency in Extrusion and Forging

Extrusion typically offers lower production costs and higher efficiency for producing complex cross-sectional shapes in large volumes due to its continuous process and minimal material waste. Forging, while generally more expensive because of higher tooling and labor costs, provides superior mechanical properties and reliability for critical components, justifying its use in high-performance applications despite slower production rates. Choosing between extrusion and forging depends on balancing cost efficiency with the desired material strength and production volume requirements.

Applications: Where to Use Extruded vs Forged Metals

Extruded metals excel in applications requiring complex cross-sectional shapes, such as automotive frames, aerospace components, and heat exchanger tubes, due to their precise dimensional control and lightweight characteristics. Forged metals are preferred in high-stress environments like crankshafts, connecting rods, and heavy machinery parts where superior strength, fatigue resistance, and impact toughness are critical. Selecting between extrusion and forging depends on specific performance needs, with extrusion favoring intricate shapes and forging prioritizing mechanical robustness.

Surface Finish and Dimensional Accuracy Comparison

Extrusion typically produces smoother surface finishes and offers better dimensional accuracy due to the controlled metal flow through dies, minimizing surface defects. Forging, while enhancing mechanical properties through grain refinement, often results in rougher surfaces that require additional machining to achieve precise dimensions. The choice between extrusion and forging depends on the desired balance of surface quality and dimensional precision for the metal component.

Choosing the Right Process: Factors to Consider

Selecting the appropriate metal shaping process depends on factors such as material type, desired mechanical properties, and production volume. Extrusion is ideal for creating complex cross-sections with good surface finish and is cost-effective for high-volume runs, while forging offers superior strength and grain refinement suited for critical load-bearing components. Consider product geometry, tolerance requirements, and budget constraints to determine whether extrusion or forging best meets application needs.

Extrusion vs Forging Infographic

materialdif.com

materialdif.com