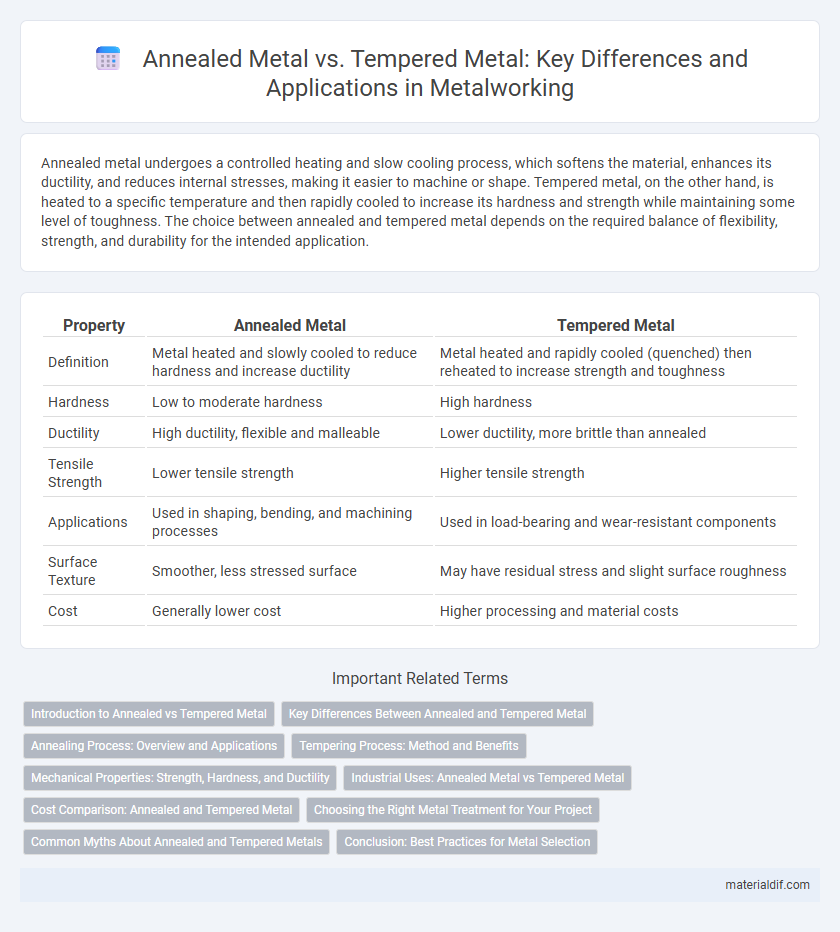

Annealed metal undergoes a controlled heating and slow cooling process, which softens the material, enhances its ductility, and reduces internal stresses, making it easier to machine or shape. Tempered metal, on the other hand, is heated to a specific temperature and then rapidly cooled to increase its hardness and strength while maintaining some level of toughness. The choice between annealed and tempered metal depends on the required balance of flexibility, strength, and durability for the intended application.

Table of Comparison

| Property | Annealed Metal | Tempered Metal |

|---|---|---|

| Definition | Metal heated and slowly cooled to reduce hardness and increase ductility | Metal heated and rapidly cooled (quenched) then reheated to increase strength and toughness |

| Hardness | Low to moderate hardness | High hardness |

| Ductility | High ductility, flexible and malleable | Lower ductility, more brittle than annealed |

| Tensile Strength | Lower tensile strength | Higher tensile strength |

| Applications | Used in shaping, bending, and machining processes | Used in load-bearing and wear-resistant components |

| Surface Texture | Smoother, less stressed surface | May have residual stress and slight surface roughness |

| Cost | Generally lower cost | Higher processing and material costs |

Introduction to Annealed vs Tempered Metal

Annealed metal undergoes a heat treatment process that softens the material, enhancing its ductility and reducing internal stresses for improved workability. Tempered metal, by contrast, is heated and then rapidly cooled to increase hardness and strength while maintaining some flexibility. Understanding the fundamental differences in their microstructures helps in selecting the right metal type for specific applications requiring either malleability or durability.

Key Differences Between Annealed and Tempered Metal

Annealed metal undergoes a slow cooling process to reduce hardness and increase ductility, making it easier to work with and less brittle. Tempered metal, on the other hand, is heated and rapidly cooled to increase strength and toughness while maintaining some level of flexibility. The key differences lie in their thermal treatments, resulting mechanical properties, and typical applications where annealed metals are preferred for forming and tempering is favored for impact resistance and durability.

Annealing Process: Overview and Applications

Annealing is a heat treatment process that involves heating metal to a specific temperature and then cooling it slowly to enhance ductility and reduce hardness. This process relieves internal stresses, making annealed metal ideal for applications requiring improved formability and machinability, such as automotive components and metal fabrication. Compared to tempered metal, annealed metal offers superior softness and malleability, enabling easier shaping and welding in manufacturing.

Tempering Process: Method and Benefits

The tempering process involves heating metal to a specific temperature below its critical point, then cooling it slowly to reduce brittleness while maintaining hardness and strength. This heat treatment method refines the microstructure, enhancing toughness, ductility, and resistance to impact compared to annealed metal. Tempered metal offers improved mechanical performance for applications requiring a balanced combination of strength and flexibility.

Mechanical Properties: Strength, Hardness, and Ductility

Annealed metal exhibits lower strength and hardness but higher ductility due to its slower cooling process, which allows for more uniform grain structures. Tempered metal, created by reheating quenched metal, balances strength and hardness with improved toughness, making it less brittle than fully hardened steel. The mechanical properties of tempered metal optimize performance under stress, offering enhanced resistance to impact and wear compared to annealed metal.

Industrial Uses: Annealed Metal vs Tempered Metal

Annealed metal, characterized by its increased ductility and reduced hardness, is widely used in industrial applications requiring extensive reshaping or welding, such as automotive body panels and metal forming processes. Tempered metal, which undergoes controlled heat treatment to enhance strength and toughness, is essential in manufacturing tools, structural components, and high-stress machinery parts. The choice between annealed and tempered metal ultimately depends on specific industrial demands, balancing malleability against mechanical strength for optimal performance.

Cost Comparison: Annealed and Tempered Metal

Annealed metal typically costs less due to its simpler heat treatment process, which involves heating and slow cooling to soften the material, making it more economical for large-scale production. Tempered metal undergoes a more complex heat treatment involving quenching and reheating to increase strength and hardness, leading to higher manufacturing expenses. The cost difference reflects the enhanced mechanical properties of tempered metal, often justifying its use in applications requiring greater durability despite the increased price.

Choosing the Right Metal Treatment for Your Project

Annealed metal features a soft, ductile structure ideal for intricate shaping and welding, whereas tempered metal offers enhanced strength and hardness through controlled heat treatment, making it suitable for impact-resistant applications. Selecting the right metal treatment depends on project requirements such as flexibility, toughness, and load-bearing capacity. Understanding the mechanical properties of annealed versus tempered metals ensures optimal performance and durability in construction, automotive, or manufacturing projects.

Common Myths About Annealed and Tempered Metals

Annealed metal is often mistakenly believed to lack strength, but it actually offers enhanced ductility and malleability compared to tempered metal, which is true since tempering increases hardness and toughness by reducing brittleness. A common myth is that tempered metal is always brittle; however, proper tempering achieves a balanced combination of strength and flexibility. Another misconception is that annealed metal cannot be hardened after treatment, whereas it serves as a foundational state for further heat treatment processes like quenching and tempering.

Conclusion: Best Practices for Metal Selection

Annealed metal offers superior ductility and ease of machining, making it ideal for applications requiring extensive forming or welding, while tempered metal provides enhanced strength and toughness suitable for structural components subjected to high stress. Selecting the appropriate metal depends on balancing mechanical properties with operational requirements such as load-bearing capacity, wear resistance, and thermal conditions. Best practices involve evaluating the metal's intended use, environmental factors, and performance criteria to ensure optimal durability and cost-effectiveness.

Annealed Metal vs Tempered Metal Infographic

materialdif.com

materialdif.com