Quenching involves rapidly cooling heated metal in water, oil, or air to increase hardness and strength by altering the microstructure, promoting martensite formation. Air cooling, a slower process, allows metal to cool naturally and uniformly, reducing internal stresses and minimizing the risk of cracking or distortion. Choosing between quenching and air cooling depends on the desired mechanical properties and the specific alloy being treated.

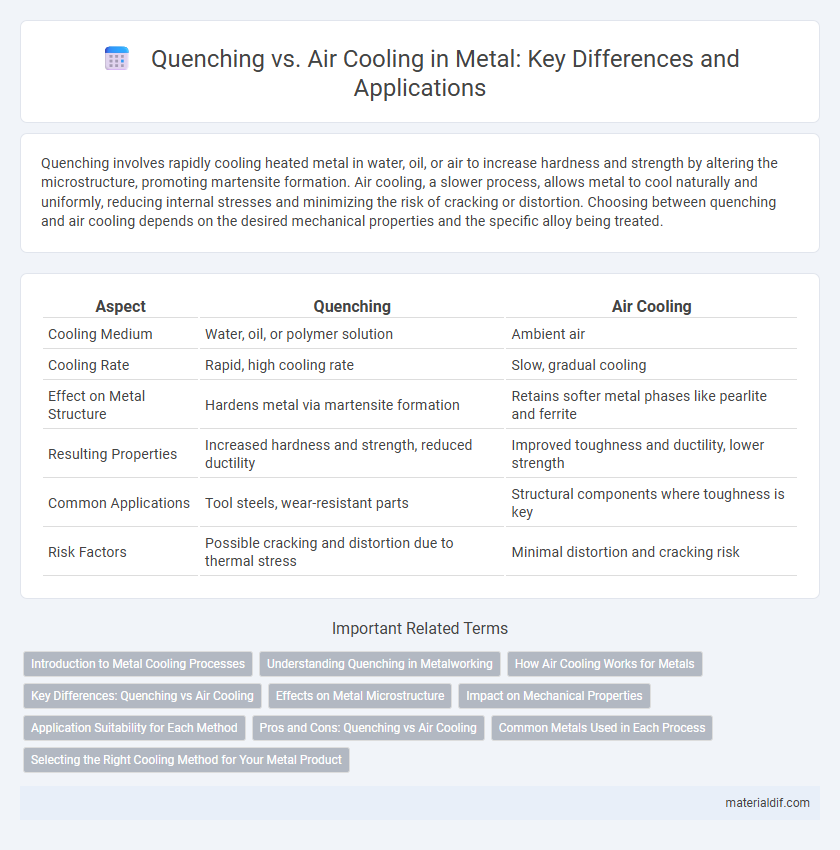

Table of Comparison

| Aspect | Quenching | Air Cooling |

|---|---|---|

| Cooling Medium | Water, oil, or polymer solution | Ambient air |

| Cooling Rate | Rapid, high cooling rate | Slow, gradual cooling |

| Effect on Metal Structure | Hardens metal via martensite formation | Retains softer metal phases like pearlite and ferrite |

| Resulting Properties | Increased hardness and strength, reduced ductility | Improved toughness and ductility, lower strength |

| Common Applications | Tool steels, wear-resistant parts | Structural components where toughness is key |

| Risk Factors | Possible cracking and distortion due to thermal stress | Minimal distortion and cracking risk |

Introduction to Metal Cooling Processes

Metal cooling processes significantly impact the mechanical properties and microstructure of metals. Quenching involves rapid cooling, typically by immersion in water or oil, resulting in increased hardness and strength due to the formation of martensite. Air cooling, a slower process, allows gradual temperature reduction, promoting pearlitic or ferritic microstructures with improved ductility and toughness.

Understanding Quenching in Metalworking

Quenching in metalworking involves rapidly cooling a heated metal object by immersing it in a liquid such as water, oil, or polymer solutions to alter its microstructure and enhance hardness and strength. This process prevents the formation of slow-cooled phases like pearlite or ferrite, resulting in a martensitic or bainitic structure with improved mechanical properties. Unlike air cooling, which allows gradual temperature reduction and softer microstructures, quenching produces a harder, more wear-resistant metal but may increase the risk of distortion or cracking if not carefully controlled.

How Air Cooling Works for Metals

Air cooling for metals works by dissipating heat through natural convection and radiation, allowing the metal to gradually reach ambient temperature without rapid thermal shock. This slower cooling process minimizes internal stresses and reduces the risk of cracking compared to quenching. The rate of heat loss depends on factors such as metal composition, surface area, and surrounding air temperature.

Key Differences: Quenching vs Air Cooling

Quenching involves rapidly cooling heated metal by immersion in water, oil, or polymer solutions, resulting in a harder, more brittle microstructure due to the formation of martensite. Air cooling allows metal to cool slowly at room temperature, producing a softer, more ductile microstructure like pearlite or ferrite. Key differences include cooling rate, resulting mechanical properties, and risk of distortion or cracking, with quenching promoting strength and hardness while air cooling maintains toughness and dimensional stability.

Effects on Metal Microstructure

Quenching rapidly cools metal, transforming austenite into martensite, resulting in a hard and brittle microstructure with increased dislocation density. Air cooling allows slower cooling rates, promoting the formation of pearlite and ferrite phases, which enhance ductility and toughness. The choice between quenching and air cooling directly influences grain size, phase distribution, and mechanical properties of the metal.

Impact on Mechanical Properties

Quenching rapidly cools metal, resulting in a harder and stronger microstructure due to the formation of martensite, significantly increasing tensile strength and hardness but reducing ductility. Air cooling allows metals to cool slowly, promoting the formation of softer phases such as pearlite and ferrite, which enhances toughness and reduces internal stresses but lowers overall hardness. The choice between quenching and air cooling directly affects mechanical properties like hardness, strength, brittleness, and ductility, crucial for tailoring metal performance in various engineering applications.

Application Suitability for Each Method

Quenching is ideal for applications requiring high hardness and strength, such as cutting tools and automotive components, due to its rapid cooling rate that transforms austenite into martensite. Air cooling suits components needing improved toughness and reduced distortion like large structural parts and castings, as it cools steel more slowly, preserving ductility. Selecting between quenching and air cooling depends on the desired mechanical properties and the size and complexity of the metal workpiece.

Pros and Cons: Quenching vs Air Cooling

Quenching rapidly cools metals, significantly increasing hardness and strength due to the formation of martensite but may cause distortion or cracking because of thermal stress. Air cooling offers a slower, more uniform cooling rate that reduces internal stresses and distortion but results in lower hardness and toughness compared to quenching. Selecting between quenching and air cooling depends on the desired balance between mechanical properties and dimensional stability in metal heat treatment processes.

Common Metals Used in Each Process

Quenching is commonly used for steel and cast iron, where rapid cooling in water, oil, or polymer solutions increases hardness and strength by forming martensite. Air cooling is typically applied to metals like aluminum alloys and copper, which require slower cooling rates to minimize internal stresses and maintain ductility. Choosing between quenching and air cooling depends on the specific metal's thermal properties and the desired mechanical characteristics.

Selecting the Right Cooling Method for Your Metal Product

Selecting the right cooling method for your metal product depends on factors such as alloy composition, desired mechanical properties, and dimensional tolerances. Quenching rapidly cools metals like steel in water or oil to increase hardness and strength but may induce residual stresses and deformation, while air cooling provides slower cooling rates that reduce the risk of warping and maintain ductility. Understanding the trade-offs between quenching and air cooling ensures optimal performance and longevity in applications ranging from automotive components to aerospace parts.

Quenching vs Air Cooling Infographic

materialdif.com

materialdif.com