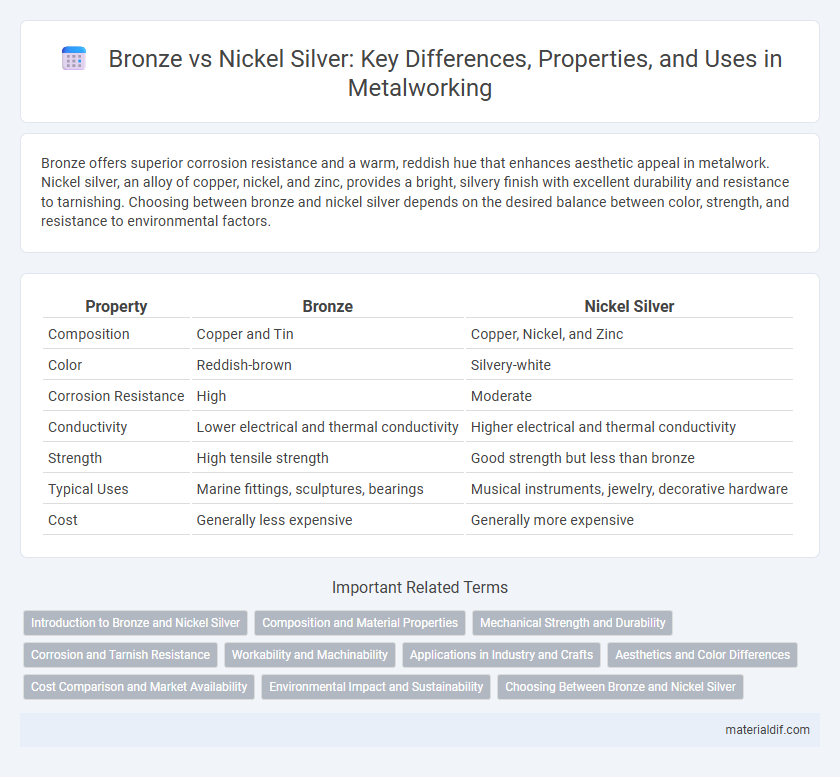

Bronze offers superior corrosion resistance and a warm, reddish hue that enhances aesthetic appeal in metalwork. Nickel silver, an alloy of copper, nickel, and zinc, provides a bright, silvery finish with excellent durability and resistance to tarnishing. Choosing between bronze and nickel silver depends on the desired balance between color, strength, and resistance to environmental factors.

Table of Comparison

| Property | Bronze | Nickel Silver |

|---|---|---|

| Composition | Copper and Tin | Copper, Nickel, and Zinc |

| Color | Reddish-brown | Silvery-white |

| Corrosion Resistance | High | Moderate |

| Conductivity | Lower electrical and thermal conductivity | Higher electrical and thermal conductivity |

| Strength | High tensile strength | Good strength but less than bronze |

| Typical Uses | Marine fittings, sculptures, bearings | Musical instruments, jewelry, decorative hardware |

| Cost | Generally less expensive | Generally more expensive |

Introduction to Bronze and Nickel Silver

Bronze, an alloy primarily composed of copper and tin, is renowned for its exceptional durability and corrosion resistance, making it ideal for sculptures and musical instruments. Nickel silver, also known as German silver, contains copper, nickel, and zinc, offering a bright, silver-like appearance without containing any actual silver. Both metals are valued in various industries, with bronze prized for its hardness and nickel silver favored for its aesthetic appeal and malleability.

Composition and Material Properties

Bronze is primarily an alloy of copper and tin, sometimes with small amounts of phosphorus or aluminum, offering high corrosion resistance and excellent strength, especially in marine environments. Nickel silver, also known as German silver, contains copper, nickel, and zinc, providing a bright, silvery finish with good malleability and moderate corrosion resistance. While bronze typically exhibits better wear resistance and durability, nickel silver excels in aesthetic appeal and is commonly used in musical instruments and decorative items.

Mechanical Strength and Durability

Bronze exhibits superior mechanical strength and durability compared to nickel silver, making it ideal for applications requiring high wear resistance and toughness. Its copper-tin alloy composition enhances corrosion resistance and longevity under mechanical stress. Nickel silver, composed mainly of copper, nickel, and zinc, offers moderate strength but is more prone to deformation and surface wear over time.

Corrosion and Tarnish Resistance

Bronze, an alloy primarily of copper and tin, exhibits excellent corrosion resistance due to the formation of a stable oxide layer that protects it from environmental damage, making it highly durable in marine and outdoor applications. Nickel silver, composed of copper, nickel, and zinc, offers superior tarnish resistance, maintaining its bright, silver-like appearance longer under typical indoor conditions but is more prone to corrosion in harsh environments compared to bronze. Choosing between bronze and nickel silver depends on the specific exposure conditions, with bronze favored for high-corrosion settings and nickel silver preferred for aesthetic applications requiring less frequent maintenance.

Workability and Machinability

Bronze offers excellent machinability due to its composition of copper and tin, providing superior wear resistance and corrosion durability in intricate machining processes. Nickel silver, an alloy of copper, nickel, and zinc, exhibits remarkable workability, enabling easy forming and soldering but generally requires more careful machining to avoid surface defects. Both metals perform well in precision manufacturing, with bronze favored for heavy-duty, high-friction components and nickel silver preferred in decorative, lightweight applications.

Applications in Industry and Crafts

Bronze, an alloy primarily of copper and tin, excels in industrial applications such as shipbuilding, bearings, and sculptures due to its corrosion resistance and durability. Nickel silver, composed of copper, nickel, and zinc, is favored in musical instruments, jewelry, and decorative hardware for its silver-like appearance and ease of engraving. Both metals serve distinct roles in crafts and manufacturing, with bronze prized for mechanical strength and nickel silver valued for aesthetic versatility.

Aesthetics and Color Differences

Bronze exhibits a warm, reddish-brown hue with a natural patina that deepens over time, offering a classic and antique aesthetic. Nickel silver, despite its name, contains no silver and features a bright, silvery-white finish with a slightly yellowish tint, providing a modern and polished appearance. The color contrast between the rich, earthy tones of bronze and the sleek, reflective surface of nickel silver significantly impacts the visual appeal and style choice in metal applications.

Cost Comparison and Market Availability

Bronze generally costs more than nickel silver due to its higher copper content and more complex alloying process, which increases production expenses. Nickel silver, often composed of copper, nickel, and zinc, is widely available at a lower price point, making it a popular choice for budget-conscious applications. Market availability favors nickel silver due to its consistent demand and easier sourcing, whereas bronze may face fluctuations related to copper market prices and mining outputs.

Environmental Impact and Sustainability

Bronze, primarily composed of copper and tin, exhibits better environmental sustainability due to its natural corrosion resistance and recyclability, reducing the need for frequent replacement and lowering resource consumption over time. Nickel silver, an alloy of copper, nickel, and zinc, may pose environmental concerns because nickel extraction has a higher ecological footprint and potential toxicity in manufacturing waste. Choosing bronze over nickel silver supports reduced environmental impact through more sustainable material sourcing and long-term durability.

Choosing Between Bronze and Nickel Silver

Choosing between bronze and nickel silver depends on the desired properties for your project; bronze offers superior corrosion resistance and strength, making it ideal for marine and industrial applications. Nickel silver, while less durable, provides a smooth, silver-like finish and is often favored for decorative items and musical instruments. Consider the environmental exposure and aesthetic requirements to determine the best metal for your needs.

Bronze vs Nickel Silver Infographic

materialdif.com

materialdif.com