Titanium offers exceptional strength-to-weight ratio and corrosion resistance, making it ideal for aerospace and medical applications where weight reduction is crucial. Inconel, a nickel-chromium superalloy, excels under extreme temperatures and oxidation, commonly used in high-stress environments like jet engines and chemical reactors. Selecting between titanium and Inconel depends on the specific requirements of temperature resistance, weight constraints, and mechanical performance.

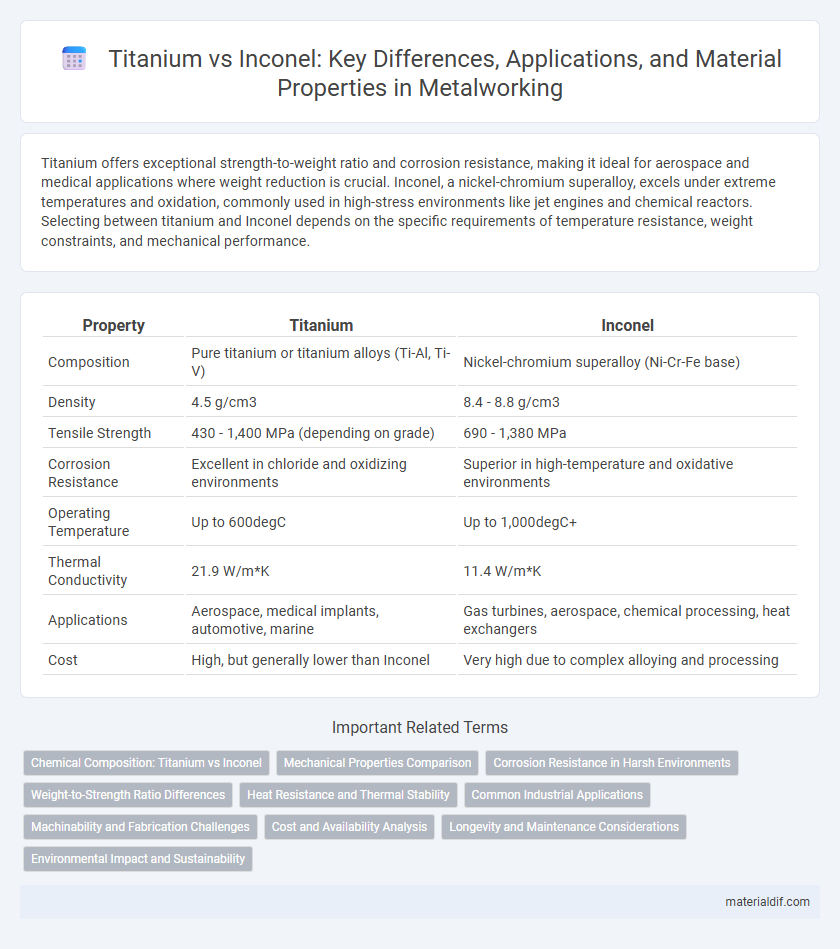

Table of Comparison

| Property | Titanium | Inconel |

|---|---|---|

| Composition | Pure titanium or titanium alloys (Ti-Al, Ti-V) | Nickel-chromium superalloy (Ni-Cr-Fe base) |

| Density | 4.5 g/cm3 | 8.4 - 8.8 g/cm3 |

| Tensile Strength | 430 - 1,400 MPa (depending on grade) | 690 - 1,380 MPa |

| Corrosion Resistance | Excellent in chloride and oxidizing environments | Superior in high-temperature and oxidative environments |

| Operating Temperature | Up to 600degC | Up to 1,000degC+ |

| Thermal Conductivity | 21.9 W/m*K | 11.4 W/m*K |

| Applications | Aerospace, medical implants, automotive, marine | Gas turbines, aerospace, chemical processing, heat exchangers |

| Cost | High, but generally lower than Inconel | Very high due to complex alloying and processing |

Chemical Composition: Titanium vs Inconel

Titanium primarily consists of titanium metal with small amounts of oxygen, iron, and aluminum, providing a high strength-to-weight ratio and excellent corrosion resistance. Inconel is a nickel-chromium-based superalloy, containing significant nickel (over 50%), chromium (15-22%), iron, molybdenum, and other elements that enhance its oxidation and heat resistance. The distinct chemical compositions result in titanium being lighter and corrosion-resistant, while Inconel offers superior performance in high-temperature and oxidative environments.

Mechanical Properties Comparison

Titanium exhibits a high strength-to-weight ratio, excellent corrosion resistance, and superior fatigue performance, making it ideal for aerospace and medical applications requiring lightweight durability. Inconel offers exceptional high-temperature strength, oxidation resistance, and creep resistance, suitable for extreme environments such as jet engines and gas turbines. While titanium excels in weight-sensitive applications with moderate temperatures, Inconel outperforms in thermal stability and mechanical strength under severe heat conditions.

Corrosion Resistance in Harsh Environments

Titanium exhibits excellent corrosion resistance in harsh environments due to its stable oxide layer, making it highly effective against seawater, chlorides, and acidic conditions. Inconel, a nickel-chromium-based superalloy, offers exceptional resistance to oxidation and pitting corrosion at high temperatures, particularly in oxidizing and reducing atmospheres. Both metals outperform many alternatives, but Titanium is preferred for chemical and marine applications, while Inconel is suited for extreme thermal and oxidative environments.

Weight-to-Strength Ratio Differences

Titanium exhibits a superior weight-to-strength ratio compared to Inconel, making it ideal for aerospace and automotive applications where reducing weight without sacrificing strength is critical. While Inconel offers exceptional high-temperature resistance and strength, its higher density results in a heavier component for equivalent strength levels. Titanium's low density of 4.5 g/cm3 combined with high tensile strength around 900 MPa delivers efficient performance in weight-sensitive engineering designs.

Heat Resistance and Thermal Stability

Titanium exhibits excellent heat resistance up to about 600degC, maintaining strength and corrosion resistance, making it suitable for moderate temperature applications. Inconel alloys outperform titanium in thermal stability, retaining structural integrity and oxidation resistance at temperatures exceeding 1000degC, ideal for extreme environments such as gas turbines and aerospace engines. The superior high-temperature performance of Inconel makes it the preferred choice where prolonged exposure to harsh thermal conditions is critical.

Common Industrial Applications

Titanium is widely used in aerospace, automotive, and medical industries for components requiring high strength-to-weight ratio and excellent corrosion resistance, such as aircraft frames and surgical implants. Inconel finds common application in high-temperature environments like gas turbines, jet engines, and chemical processing plants due to its exceptional oxidation and heat resistance. Both metals serve critical roles in manufacturing, with titanium favored for lightweight durability and Inconel preferred for extreme heat and corrosion conditions.

Machinability and Fabrication Challenges

Titanium exhibits lower machinability due to its high strength-to-weight ratio and tendency to work harden rapidly, requiring specialized tooling and slower cutting speeds. Inconel, a nickel-chromium superalloy, presents more significant fabrication challenges because of its extreme hardness, high-temperature strength, and poor thermal conductivity that cause rapid tool wear and difficulty in heat dissipation. Both metals demand precise control of cutting parameters and advanced cooling techniques to optimize machining efficiency and minimize tool damage.

Cost and Availability Analysis

Titanium offers a lower cost per pound compared to Inconel, making it more economical for large-scale applications, while Inconel's higher price is driven by its complex alloying and production processes. Inconel boasts superior high-temperature corrosion resistance, which justifies its premium in aerospace and chemical processing industries despite limited availability due to fewer suppliers. Titanium's widespread availability and established supply chains contribute to its favorable cost-effectiveness in manufacturing and construction sectors.

Longevity and Maintenance Considerations

Titanium offers exceptional corrosion resistance and light weight, making it ideal for long-lasting applications with minimal maintenance in oxidizing environments. Inconel excels in high-temperature environments due to its superior creep and oxidation resistance but may require more frequent inspections to monitor for stress corrosion cracking. Choosing between titanium and Inconel depends on operating conditions, with titanium favored for longevity in corrosive media and Inconel preferred for durability under extreme thermal stress.

Environmental Impact and Sustainability

Titanium offers superior environmental benefits due to its abundance, recyclability, and low toxicity compared to Inconel, which relies heavily on nickel and chromium, elements linked to higher ecological extraction costs and pollution. The production of titanium generates fewer greenhouse gas emissions and consumes less energy, enhancing its sustainability profile in aerospace and medical applications. In contrast, Inconel's high corrosion resistance comes at the expense of a more carbon-intensive manufacturing process, affecting its long-term environmental footprint.

Titanium vs Inconel Infographic

materialdif.com

materialdif.com