Passivation enhances metal corrosion resistance by forming a protective oxide layer, typically on stainless steel surfaces, without removing base material. Pickling involves a chemical treatment that removes surface impurities, such as rust and scale, preparing the metal for further processing or finishing. Both processes improve metal durability but serve different roles: passivation preserves while pickling cleans.

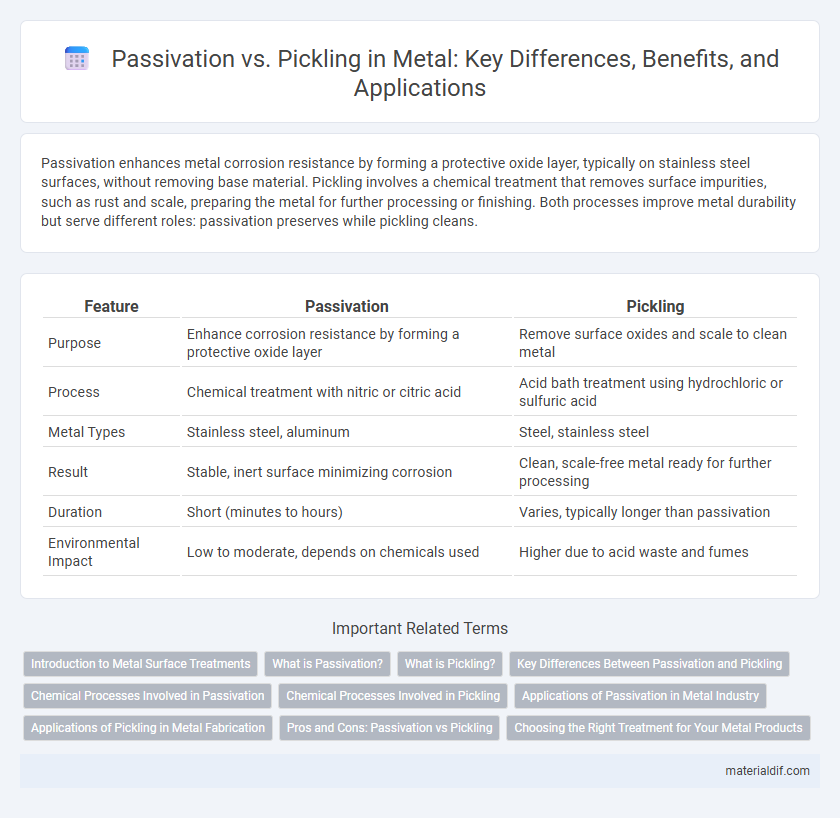

Table of Comparison

| Feature | Passivation | Pickling |

|---|---|---|

| Purpose | Enhance corrosion resistance by forming a protective oxide layer | Remove surface oxides and scale to clean metal |

| Process | Chemical treatment with nitric or citric acid | Acid bath treatment using hydrochloric or sulfuric acid |

| Metal Types | Stainless steel, aluminum | Steel, stainless steel |

| Result | Stable, inert surface minimizing corrosion | Clean, scale-free metal ready for further processing |

| Duration | Short (minutes to hours) | Varies, typically longer than passivation |

| Environmental Impact | Low to moderate, depends on chemicals used | Higher due to acid waste and fumes |

Introduction to Metal Surface Treatments

Passivation and pickling are essential metal surface treatments that enhance corrosion resistance and prepare metals for further processing. Passivation involves creating a protective oxide layer, typically on stainless steel, to prevent oxidation, while pickling uses acid solutions to remove surface impurities like rust and scale. Both processes improve metal durability and longevity, with passivation focusing on protection and pickling on surface cleaning.

What is Passivation?

Passivation is a chemical treatment process that enhances the corrosion resistance of metal surfaces, particularly stainless steel, by forming a thin, inert oxide layer. This oxide layer prevents oxidation and inhibits rust formation by removing free iron and other contaminants from the metal surface. Unlike pickling, which uses acidic solutions to clean and remove scale, passivation focuses on improving the metal's protective properties without altering its appearance or structural integrity.

What is Pickling?

Pickling is a metal surface treatment process that involves immersing steel or other metal alloys in an acid solution, such as hydrochloric or sulfuric acid, to remove rust, scale, and impurities from the surface. This chemical cleaning enhances metal adhesion for subsequent coatings and improves corrosion resistance by creating a clean, reactive surface. Pickling differs from passivation by actively stripping contaminants rather than forming a protective oxide layer.

Key Differences Between Passivation and Pickling

Passivation enhances the corrosion resistance of stainless steel by creating a thin, protective oxide layer through chemical treatment, whereas pickling involves the removal of surface contaminants and oxides using strong acids like nitric and hydrofluoric acid. Passivation primarily preserves the metal's surface integrity while pickling aggressively cleans the metal, often preparing it for further processing or finishing. Key differences include the purpose--corrosion protection versus cleaning--and the chemical processes involved, where passivation is a controlled oxidation and pickling is a chemical etching.

Chemical Processes Involved in Passivation

Passivation involves creating a protective oxide layer on metal surfaces through controlled chemical reactions, typically using nitric acid or citric acid solutions to remove free iron and enhance corrosion resistance. This chemical process stabilizes the metal by forming a thin, inert oxide film that prevents further oxidation and environmental damage. In contrast, pickling utilizes stronger acids like hydrochloric or sulfuric acid to aggressively strip away scale, rust, and oxides before subsequent treatments like passivation.

Chemical Processes Involved in Pickling

Pickling involves the chemical removal of oxides and scale from metal surfaces using strong acids such as hydrochloric or sulfuric acid, which react with iron oxides to form soluble metal salts. This process restores the metal's surface to a clean, reactive state, enhancing its appearance and preparing it for subsequent treatments like passivation or coating. The acids used in pickling must be carefully neutralized and disposed of due to their corrosive nature and environmental impact.

Applications of Passivation in Metal Industry

Passivation is widely applied in the metal industry to enhance corrosion resistance, particularly in stainless steel components used in automotive, aerospace, and medical devices. This chemical treatment forms a thin, inert oxide layer that prevents surface oxidation and prolongs the lifespan of metal parts in harsh environments. Unlike pickling, which primarily removes scale and rust, passivation stabilizes the metal surface without damaging its structural integrity.

Applications of Pickling in Metal Fabrication

Pickling is widely applied in metal fabrication to remove oxides, scale, and impurities from stainless steel and carbon steel surfaces, ensuring enhanced paint adhesion and corrosion resistance. It is crucial in preparing metal surfaces prior to welding, coating, or further finishing processes to improve joint quality and longevity. Industrial applications include cleaning steel sheets, pipes, and components used in automotive, construction, and aerospace manufacturing.

Pros and Cons: Passivation vs Pickling

Passivation enhances corrosion resistance by forming a protective oxide layer on stainless steel, offering long-term durability with minimal surface damage, but it may not remove heavy scale or rust effectively. Pickling aggressively removes oxides, scale, and contaminants through acid treatment, providing thorough surface cleaning but posing risks of metal loss and hazardous chemical handling. Choosing between passivation and pickling depends on the metal condition, desired corrosion resistance, and safety considerations.

Choosing the Right Treatment for Your Metal Products

Passivation enhances corrosion resistance by forming a protective oxide layer on stainless steel surfaces, making it ideal for preserving metal integrity without aggressive chemical exposure. Pickling involves using strong acids to remove scale, rust, and contaminants, offering a thorough cleaning process especially suited for heavily oxidized or contaminated metals. Selecting between passivation and pickling depends on the metal condition and desired surface quality, with passivation preferred for mild cleaning and long-term protection, while pickling is chosen for deep cleaning prior to further processing.

Passivation vs Pickling Infographic

materialdif.com

materialdif.com