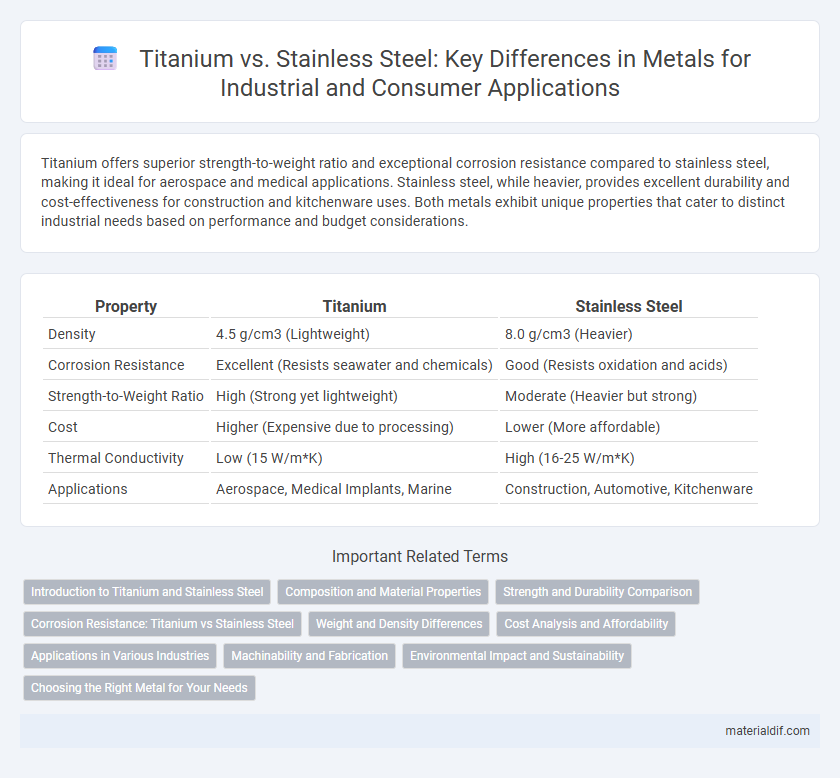

Titanium offers superior strength-to-weight ratio and exceptional corrosion resistance compared to stainless steel, making it ideal for aerospace and medical applications. Stainless steel, while heavier, provides excellent durability and cost-effectiveness for construction and kitchenware uses. Both metals exhibit unique properties that cater to distinct industrial needs based on performance and budget considerations.

Table of Comparison

| Property | Titanium | Stainless Steel |

|---|---|---|

| Density | 4.5 g/cm3 (Lightweight) | 8.0 g/cm3 (Heavier) |

| Corrosion Resistance | Excellent (Resists seawater and chemicals) | Good (Resists oxidation and acids) |

| Strength-to-Weight Ratio | High (Strong yet lightweight) | Moderate (Heavier but strong) |

| Cost | Higher (Expensive due to processing) | Lower (More affordable) |

| Thermal Conductivity | Low (15 W/m*K) | High (16-25 W/m*K) |

| Applications | Aerospace, Medical Implants, Marine | Construction, Automotive, Kitchenware |

Introduction to Titanium and Stainless Steel

Titanium is a lightweight, corrosion-resistant metal known for its high strength-to-weight ratio and excellent biocompatibility, making it ideal for aerospace, medical implants, and high-performance engineering applications. Stainless steel, an alloy primarily composed of iron, chromium, and nickel, offers superior durability, corrosion resistance, and affordability, widely used in construction, kitchenware, and industrial equipment. Both metals exhibit distinct properties tailored to specific applications, with titanium valued for its lightness and strength, while stainless steel is prized for its toughness and cost-effectiveness.

Composition and Material Properties

Titanium consists mainly of titanium with trace elements such as aluminum and vanadium, resulting in a lightweight metal with exceptional strength-to-weight ratio and excellent corrosion resistance in harsh environments. Stainless steel is an alloy primarily composed of iron, chromium (at least 10.5%), and nickel, offering superior hardness, durability, and resistance to oxidation and staining under normal atmospheric conditions. Titanium exhibits low density and higher resistance to fatigue, while stainless steel provides greater tensile strength and cost-effectiveness for structural applications.

Strength and Durability Comparison

Titanium exhibits a higher strength-to-weight ratio compared to stainless steel, making it exceptionally strong while remaining lightweight. Its superior corrosion resistance and resilience under extreme conditions ensure longer durability in harsh environments. Stainless steel, though less strong, offers excellent toughness and is more cost-effective for applications requiring moderate strength and good durability.

Corrosion Resistance: Titanium vs Stainless Steel

Titanium exhibits superior corrosion resistance compared to stainless steel, especially in highly aggressive environments such as seawater and chloride-rich conditions. Its passive oxide layer provides exceptional protection against pitting, crevice corrosion, and stress corrosion cracking, outperforming commonly used stainless steel grades like 304 and 316. While stainless steel offers good corrosion resistance in many applications, titanium is preferred for highly corrosive industrial and marine environments due to its enhanced durability and longer service life.

Weight and Density Differences

Titanium has a density of approximately 4.5 g/cm3, making it about 45% lighter than stainless steel, which has a density around 8 g/cm3. This significant weight difference allows titanium to offer comparable strength with reduced mass, ideal for aerospace and medical applications. Stainless steel's higher density contributes to its durability and corrosion resistance but results in heavier components compared to titanium.

Cost Analysis and Affordability

Titanium generally commands a higher price than stainless steel due to its superior strength-to-weight ratio and corrosion resistance, making it a premium choice in aerospace and medical industries. Stainless steel, particularly grades like 304 and 316, offers a cost-effective alternative with excellent durability and corrosion resistance suitable for everyday applications. When analyzing affordability, the initial investment in titanium may be offset by its longevity and reduced maintenance costs, while stainless steel remains favored for budget-sensitive projects requiring reliable performance.

Applications in Various Industries

Titanium is extensively used in aerospace, medical implants, and chemical processing due to its remarkable strength-to-weight ratio, corrosion resistance, and biocompatibility. Stainless steel finds widespread application in construction, automotive, food processing, and household appliances because of its durability, corrosion resistance, and ease of fabrication. Industries select titanium for lightweight, high-performance needs, while stainless steel is preferred for cost-effective, versatile structural components.

Machinability and Fabrication

Titanium offers excellent strength-to-weight ratio but presents challenges in machinability due to its tendency to gall and work-harden, requiring specialized tooling and slower cutting speeds. Stainless steel, particularly austenitic grades, provides better machinability with conventional tools and higher cutting speeds, though it is heavier and less corrosion-resistant than titanium. Fabrication of titanium demands precise control of heat and environment to avoid contamination, while stainless steel fabrication is more forgiving, allowing for widely available welding and forming techniques.

Environmental Impact and Sustainability

Titanium offers a lower environmental impact compared to stainless steel due to its higher strength-to-weight ratio, which reduces material usage and energy consumption during transportation and manufacturing. Its corrosion resistance extends product lifespan, decreasing waste and resource demand. Although titanium production requires significant energy, its durability and recyclability contribute to greater long-term sustainability than stainless steel.

Choosing the Right Metal for Your Needs

Titanium offers superior strength-to-weight ratio and exceptional corrosion resistance, making it ideal for aerospace, medical implants, and high-performance applications. Stainless steel provides excellent durability, cost-effectiveness, and resistance to oxidation, suitable for construction, cookware, and automotive industries. Selecting the right metal depends on factors like weight requirements, environmental exposure, budget constraints, and mechanical performance needs.

Titanium vs Stainless Steel Infographic

materialdif.com

materialdif.com