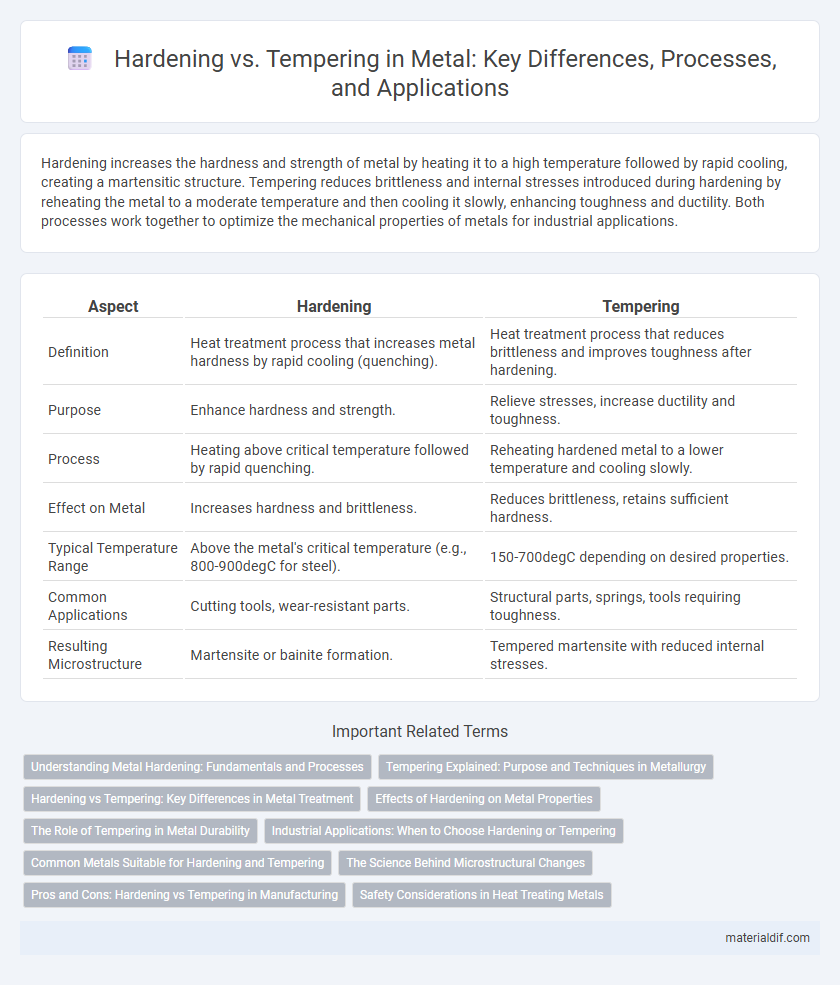

Hardening increases the hardness and strength of metal by heating it to a high temperature followed by rapid cooling, creating a martensitic structure. Tempering reduces brittleness and internal stresses introduced during hardening by reheating the metal to a moderate temperature and then cooling it slowly, enhancing toughness and ductility. Both processes work together to optimize the mechanical properties of metals for industrial applications.

Table of Comparison

| Aspect | Hardening | Tempering |

|---|---|---|

| Definition | Heat treatment process that increases metal hardness by rapid cooling (quenching). | Heat treatment process that reduces brittleness and improves toughness after hardening. |

| Purpose | Enhance hardness and strength. | Relieve stresses, increase ductility and toughness. |

| Process | Heating above critical temperature followed by rapid quenching. | Reheating hardened metal to a lower temperature and cooling slowly. |

| Effect on Metal | Increases hardness and brittleness. | Reduces brittleness, retains sufficient hardness. |

| Typical Temperature Range | Above the metal's critical temperature (e.g., 800-900degC for steel). | 150-700degC depending on desired properties. |

| Common Applications | Cutting tools, wear-resistant parts. | Structural parts, springs, tools requiring toughness. |

| Resulting Microstructure | Martensite or bainite formation. | Tempered martensite with reduced internal stresses. |

Understanding Metal Hardening: Fundamentals and Processes

Metal hardening involves increasing the strength and durability of steel by heating it to a specific temperature and then rapidly cooling it through quenching, causing a transformation in the metal's microstructure. Tempering follows hardening by reheating the quenched metal to a lower temperature, reducing brittleness while maintaining improved hardness, which balances toughness and strength. Understanding this heat treatment sequence is essential for optimizing mechanical properties in tool steels, automotive components, and structural materials.

Tempering Explained: Purpose and Techniques in Metallurgy

Tempering is a heat treatment process used to improve the toughness and ductility of hardened steel by reheating it to a temperature below its critical point, followed by controlled cooling. The primary purpose is to reduce brittleness caused by quenching while maintaining sufficient hardness for wear resistance. Common tempering techniques involve precise temperature control and time durations, typically ranging from 150degC to 650degC, to tailor mechanical properties for specific industrial applications.

Hardening vs Tempering: Key Differences in Metal Treatment

Hardening increases metal hardness by heating and rapidly cooling to form martensite, enhancing strength but causing brittleness. Tempering follows hardening, reheating the metal below critical temperature to reduce brittleness and improve toughness without significantly lowering hardness. The key difference lies in hardening's focus on maximum strength and tempering's role in balancing hardness with ductility for optimal metal performance.

Effects of Hardening on Metal Properties

Hardening significantly increases metal's hardness and strength by transforming its microstructure, often through rapid cooling or quenching, which traps carbon atoms in a distorted lattice. This process improves wear resistance but can also lead to increased brittleness and residual stresses within the metal, reducing its ductility and toughness. The altered grain structure from hardening makes metals ideal for tools and machinery components requiring high durability under mechanical stress.

The Role of Tempering in Metal Durability

Tempering plays a critical role in enhancing metal durability by reducing brittleness and increasing toughness after hardening processes such as quenching. This heat treatment lowers internal stresses and refines the microstructure, resulting in improved resistance to cracking and fatigue. Properly tempered steel balances hardness with ductility, optimizing performance in demanding applications like automotive components and cutting tools.

Industrial Applications: When to Choose Hardening or Tempering

Hardening enhances metal's hardness and wear resistance by rapidly cooling it from a high temperature, making it ideal for cutting tools and machinery parts subjected to heavy stress. Tempering follows hardening to reduce brittleness and improve toughness, crucial for components like gears and springs that experience impact and cyclic loads. Selecting between hardening and tempering depends on balancing hardness with ductility to meet specific industrial application demands for durability and performance.

Common Metals Suitable for Hardening and Tempering

Common metals suitable for hardening and tempering include carbon steel, alloy steel, and tool steel, each offering enhanced strength and wear resistance through heat treatment processes. Carbon steels with 0.3-1.0% carbon content respond well to hardening and tempering, improving toughness while maintaining hardness. Alloy steels containing elements like chromium, molybdenum, and vanadium exhibit superior hardenability and tempering stability, making them ideal for high-stress applications.

The Science Behind Microstructural Changes

Hardening transforms steel's microstructure by rapidly cooling it from a high temperature, creating martensite which increases hardness but also brittleness. Tempering follows by reheating the hardened steel to a moderate temperature, allowing some martensite to decompose into tempered martensite or ferrite, thereby reducing brittleness and improving toughness. These microstructural changes balance hardness and ductility, optimizing the metal's mechanical properties for specific applications.

Pros and Cons: Hardening vs Tempering in Manufacturing

Hardening increases metal's strength and wear resistance by rapidly cooling after heating, but it often makes the metal brittle and prone to cracking. Tempering reduces brittleness and improves toughness by reheating hardened metal to a lower temperature, though it slightly decreases hardness. Manufacturers balance these processes to optimize durability and machinability depending on application requirements.

Safety Considerations in Heat Treating Metals

Hardening involves heating metal to a high temperature and rapidly cooling it, which can induce internal stresses leading to cracks or fractures if not carefully controlled. Tempering follows hardening by reheating the metal to a lower temperature, reducing brittleness and improving safety by minimizing the risk of sudden failure during use. Ensuring proper temperature control and cooling rates during both processes is critical to prevent hazards such as thermal shock or structural weaknesses.

Hardening vs Tempering Infographic

materialdif.com

materialdif.com