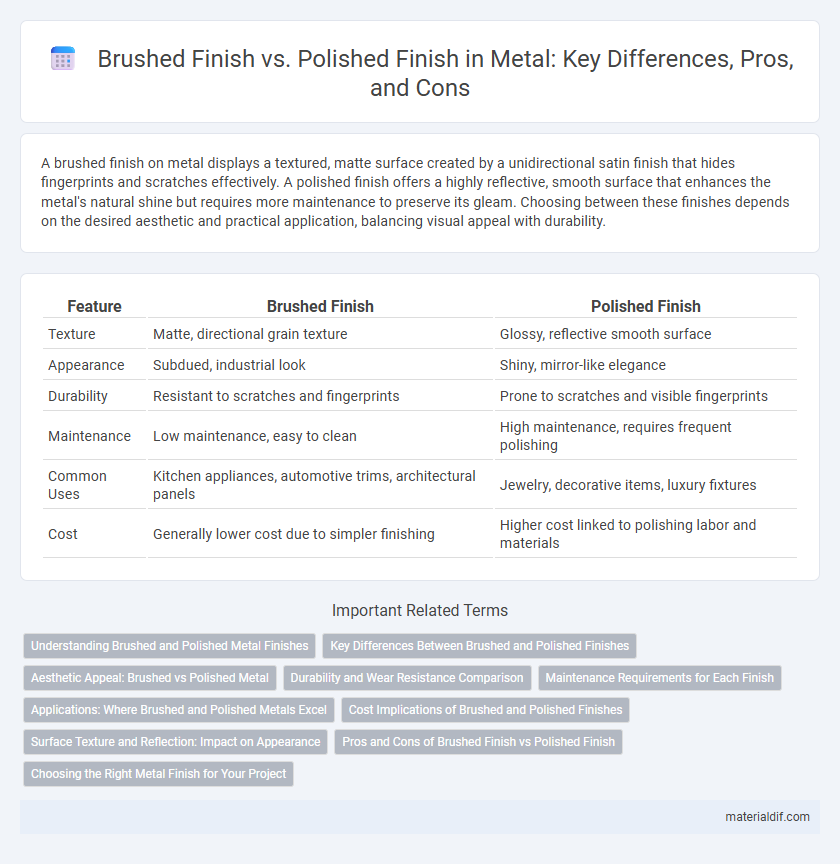

A brushed finish on metal displays a textured, matte surface created by a unidirectional satin finish that hides fingerprints and scratches effectively. A polished finish offers a highly reflective, smooth surface that enhances the metal's natural shine but requires more maintenance to preserve its gleam. Choosing between these finishes depends on the desired aesthetic and practical application, balancing visual appeal with durability.

Table of Comparison

| Feature | Brushed Finish | Polished Finish |

|---|---|---|

| Texture | Matte, directional grain texture | Glossy, reflective smooth surface |

| Appearance | Subdued, industrial look | Shiny, mirror-like elegance |

| Durability | Resistant to scratches and fingerprints | Prone to scratches and visible fingerprints |

| Maintenance | Low maintenance, easy to clean | High maintenance, requires frequent polishing |

| Common Uses | Kitchen appliances, automotive trims, architectural panels | Jewelry, decorative items, luxury fixtures |

| Cost | Generally lower cost due to simpler finishing | Higher cost linked to polishing labor and materials |

Understanding Brushed and Polished Metal Finishes

Brushed metal finishes feature a unidirectional satin texture created by fine abrasives, enhancing scratch resistance and offering a matte, non-reflective appearance ideal for industrial and modern designs. Polished metal finishes undergo extensive buffing to achieve a smooth, mirror-like surface that maximizes reflectivity and highlights the metal's natural luster, commonly used in decorative and luxury applications. Understanding these finishes aids in selecting the right aesthetic and functional properties for metal surfaces in architecture, automotive, and consumer electronics industries.

Key Differences Between Brushed and Polished Finishes

Brushed finishes feature a textured surface created by abrasive brushes that produce fine lines, reducing glare and hiding fingerprints, making them ideal for industrial and modern design applications. Polished finishes have a smooth, reflective surface achieved through buffing and polishing processes, enhancing shine and visual appeal but showing scratches and fingerprints more easily. The key difference lies in appearance and maintenance: brushed finishes offer a matte, durable look with less visibility of wear, while polished finishes provide a glossy, elegant finish requiring more careful upkeep.

Aesthetic Appeal: Brushed vs Polished Metal

Brushed finish metal features a textured surface with fine lines, creating a matte, industrial look that reduces glare and fingerprints, enhancing durability in high-traffic applications. Polished finish metal offers a mirror-like shine with a smooth surface that reflects light vividly, providing a luxurious and elegant aesthetic ideal for decorative elements. The choice between brushed and polished metal significantly impacts the visual style, with brushed finishes conveying a subtle, understated appeal and polished finishes emphasizing brightness and sophistication.

Durability and Wear Resistance Comparison

Brushed metal finishes feature fine surface scratches that enhance wear resistance by masking minor scratches and reducing the visibility of fingerprints and smudges. Polished finishes, while visually striking with their smooth, reflective surface, are more prone to showing scratches, dents, and everyday wear due to their high gloss. Durability-wise, brushed finishes provide better long-term resilience in high-traffic or industrial environments, whereas polished finishes require more maintenance to preserve their pristine appearance.

Maintenance Requirements for Each Finish

Brushed metal finishes require regular cleaning to maintain their texture but are more forgiving of fingerprints and minor scratches, making them ideal for high-traffic areas. Polished metal finishes demand frequent polishing and careful handling to preserve their mirror-like shine and are more susceptible to smudges and corrosion. Choosing between brushed and polished finishes depends on the balance between maintenance effort and desired aesthetic appeal.

Applications: Where Brushed and Polished Metals Excel

Brushed finish metals are ideal for applications requiring texture and grip, such as kitchen appliances, architectural panels, and automotive trim, where their matte surface reduces glare and hides fingerprints. Polished finish metals excel in decorative and high-visibility settings like jewelry, mirrors, and luxury car parts, offering a reflective, mirror-like shine that enhances aesthetic appeal. Both finishes serve functional purposes in tools and equipment, with brushed finishes providing durability and polished finishes allowing easy cleaning and corrosion resistance.

Cost Implications of Brushed and Polished Finishes

Brushed metal finishes generally incur lower costs due to simpler production processes and less labor-intensive surface preparation compared to polished finishes. Polished finishes demand higher expenses as they require extensive buffing, polishing compounds, and skilled craftsmanship to achieve a mirror-like surface. Maintenance costs also differ, with brushed finishes more forgiving to scratches and fingerprints, reducing long-term upkeep expenses.

Surface Texture and Reflection: Impact on Appearance

Brushed finish metal features a textured surface with fine linear scratches, creating a matte appearance that diffuses light and reduces glare, making it ideal for hiding fingerprints and minor imperfections. Polished finish metal has a smooth, reflective surface that enhances brightness and shine by reflecting light sharply, producing a mirror-like effect with high gloss. The choice between brushed and polished finishes significantly impacts the metal's visual appeal, where brushed surfaces offer understated elegance and polished surfaces provide a striking, luminous look.

Pros and Cons of Brushed Finish vs Polished Finish

Brushed finish offers a matte texture that effectively hides fingerprints and scratches, making it ideal for high-traffic areas, while polished finish provides a mirror-like shine that enhances aesthetic appeal but shows smudges and imperfections more easily. The brushed surface tends to be more resistant to wear and requires less maintenance, contrasting with the polished finish, which demands frequent cleaning to preserve its glossy look. Choosing between brushed and polished finishes depends on balancing durability and low upkeep against elegance and visual impact.

Choosing the Right Metal Finish for Your Project

Brushed finish metal offers a textured, matte appearance that minimizes the visibility of scratches and fingerprints, making it ideal for high-traffic or industrial applications. Polished finish metal provides a smooth, reflective surface that enhances aesthetic appeal but requires more maintenance to preserve its shine. Selecting the right finish depends on balancing durability, maintenance needs, and the desired visual impact for your metal project.

Brushed Finish vs Polished Finish Infographic

materialdif.com

materialdif.com