Welding creates a strong, permanent bond by melting base metals and adding filler material, making it ideal for structural applications requiring high strength. Brazing uses a filler metal with a lower melting point than the base metals, joining them without melting the base metals, which preserves their integrity and reduces distortion. While welding provides superior strength, brazing offers advantages in joining dissimilar metals and delicate components with minimal thermal impact.

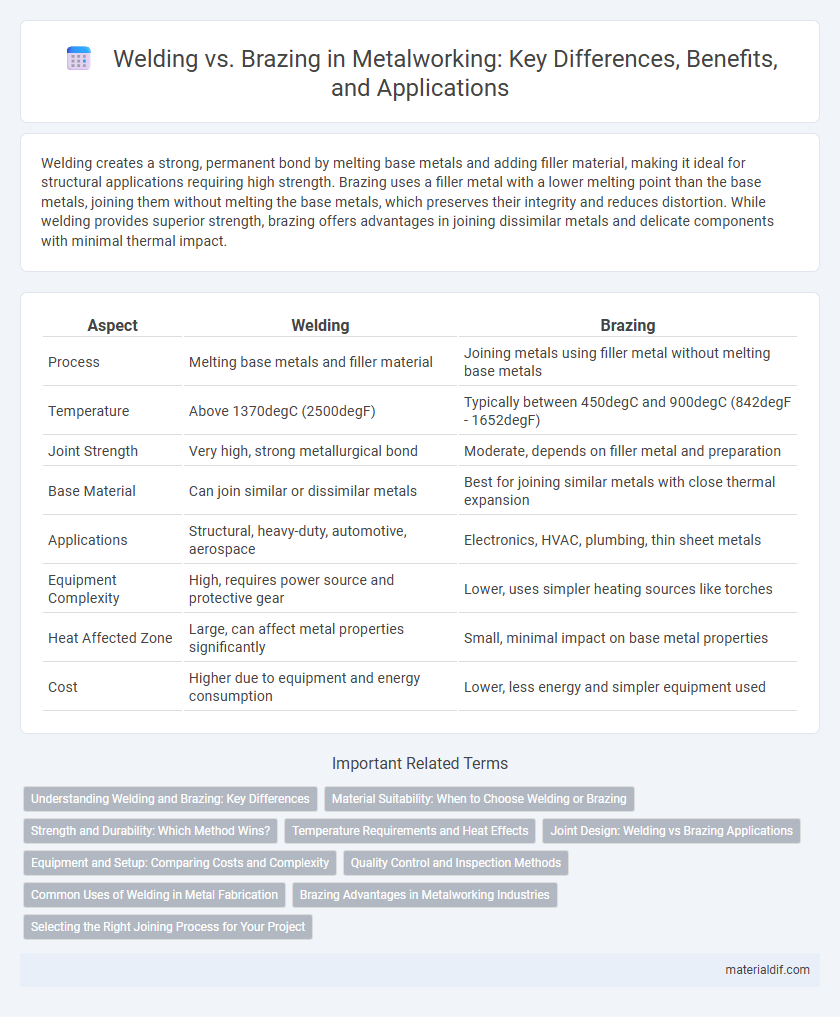

Table of Comparison

| Aspect | Welding | Brazing |

|---|---|---|

| Process | Melting base metals and filler material | Joining metals using filler metal without melting base metals |

| Temperature | Above 1370degC (2500degF) | Typically between 450degC and 900degC (842degF - 1652degF) |

| Joint Strength | Very high, strong metallurgical bond | Moderate, depends on filler metal and preparation |

| Base Material | Can join similar or dissimilar metals | Best for joining similar metals with close thermal expansion |

| Applications | Structural, heavy-duty, automotive, aerospace | Electronics, HVAC, plumbing, thin sheet metals |

| Equipment Complexity | High, requires power source and protective gear | Lower, uses simpler heating sources like torches |

| Heat Affected Zone | Large, can affect metal properties significantly | Small, minimal impact on base metal properties |

| Cost | Higher due to equipment and energy consumption | Lower, less energy and simpler equipment used |

Understanding Welding and Brazing: Key Differences

Welding and brazing are metal joining techniques that differ primarily in temperature and the way metals fuse. Welding involves melting the base metals and filler material to create a strong, homogeneous joint, typically at temperatures above 1,400degF (760degC). Brazing joins metals by melting a filler metal at lower temperatures, usually above 840degF (450degC), without melting the base metals, resulting in a bonded joint with distinct material interfaces.

Material Suitability: When to Choose Welding or Brazing

Welding is ideal for joining steel, stainless steel, and other ferrous metals that require high-strength, load-bearing joints, especially in structural applications. Brazing suits non-ferrous metals like copper, brass, and aluminum or dissimilar metal combinations where lower heat input preserves material properties and reduces distortion. Choose welding for high-stress environments and brazing when joining thin or heat-sensitive materials with minimal metallurgical impact.

Strength and Durability: Which Method Wins?

Welding creates stronger, more durable joints by melting base metals and forming a continuous bond that withstands high stress and temperature variations. Brazing, while offering good strength for thin or dissimilar metals, relies on a filler metal that doesn't melt the base materials, resulting in joints that are less resilient under heavy mechanical loads. For applications demanding maximum strength and long-term durability, welding remains the superior method.

Temperature Requirements and Heat Effects

Welding typically requires higher temperatures, often exceeding 1,300degC (2,372degF), to melt the base metals and fuse them together, resulting in strong and permanent joints but with significant heat-affected zones (HAZ) that can alter the metal's microstructure. Brazing operates at lower temperatures, generally between 450degC and 1,100degC (840degF to 2,012degF), melting only the filler metal without melting the base metals, which minimizes thermal distortion and preserves the integrity of the heat-affected zone. The lower heat input in brazing reduces residual stresses and warping compared to the intense thermal cycles and metallurgical changes induced by welding.

Joint Design: Welding vs Brazing Applications

Welding creates strong, continuous joints by melting base metals, ideal for heavy-duty applications requiring high strength and structural integrity. Brazing joins metals using a filler with a lower melting point, preserving the base metal's properties and allowing for more intricate joint designs in delicate or heat-sensitive applications. The joint design in welding often involves full penetration and fusion, while brazing designs focus on precise gap control and capillary action for effective bonding.

Equipment and Setup: Comparing Costs and Complexity

Welding equipment typically requires higher upfront costs due to the need for power sources, gas supplies, and safety gear, whereas brazing setups are generally more cost-effective with simpler torch and filler metal requirements. Welding demands complex machinery and precise control to handle high temperatures and melting metal, increasing operational complexity. Brazing involves lower temperatures and less specialized equipment, resulting in easier setup and reduced maintenance expenses.

Quality Control and Inspection Methods

Welding quality control relies heavily on non-destructive testing methods such as ultrasonic testing, radiographic inspection, and dye penetrant examination to detect internal and surface defects. Brazing inspection emphasizes visual inspection and leak testing due to the capillary action bonding that requires consistent joint fill and clean interfaces. Both processes benefit from hardness testing and metallurgical analysis to ensure joint integrity and compliance with industry standards.

Common Uses of Welding in Metal Fabrication

Welding is commonly used in metal fabrication for constructing structural frameworks, manufacturing automotive components, and assembling heavy machinery due to its ability to create strong, permanent joints. It enables the joining of thick metals and diverse alloys, providing high strength essential for load-bearing applications. Welding processes such as MIG, TIG, and arc welding offer precision and durability that are critical in shipbuilding, aerospace, and industrial equipment production.

Brazing Advantages in Metalworking Industries

Brazing offers superior joint strength and precision compared to welding, making it ideal for delicate or thin metal components commonly used in aerospace and electronics industries. It requires lower temperatures, reducing thermal distortion and preserving the integrity of heat-sensitive alloys such as aluminum and copper. Its ability to join dissimilar metals efficiently enhances versatility and corrosion resistance in automotive and HVAC applications.

Selecting the Right Joining Process for Your Project

Welding creates strong, molten metal joints by melting base metals, ideal for high-stress or load-bearing applications requiring durability and structural integrity. Brazing joins metals using a filler metal with a lower melting point, producing clean connections without melting base metals, suitable for delicate or thin materials needing precise, heat-sensitive bonding. Choosing the right process depends on material type, joint strength requirements, thermal sensitivity, and application conditions.

Welding vs Brazing Infographic

materialdif.com

materialdif.com