Ductile iron exhibits superior tensile strength and impact resistance compared to gray iron due to its nodular graphite structure, making it ideal for applications requiring durability and flexibility. Gray iron, characterized by its flake graphite formation, offers excellent vibration damping and machinability but is more brittle and prone to cracking under stress. Choosing between ductile and gray iron depends on the balance needed between strength, toughness, and castability for specific industrial uses.

Table of Comparison

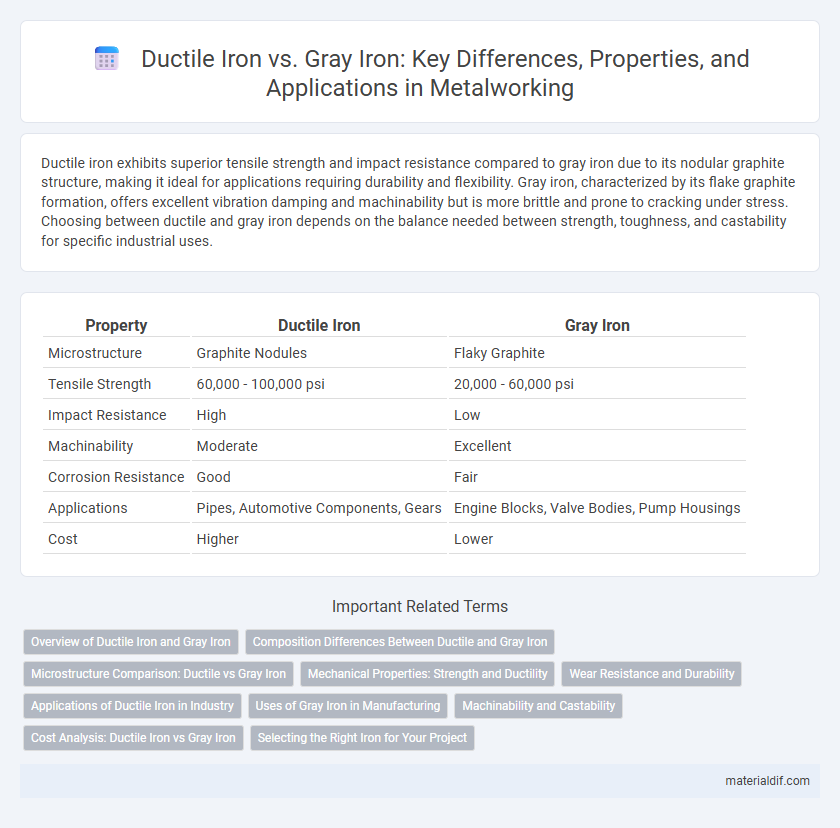

| Property | Ductile Iron | Gray Iron |

|---|---|---|

| Microstructure | Graphite Nodules | Flaky Graphite |

| Tensile Strength | 60,000 - 100,000 psi | 20,000 - 60,000 psi |

| Impact Resistance | High | Low |

| Machinability | Moderate | Excellent |

| Corrosion Resistance | Good | Fair |

| Applications | Pipes, Automotive Components, Gears | Engine Blocks, Valve Bodies, Pump Housings |

| Cost | Higher | Lower |

Overview of Ductile Iron and Gray Iron

Ductile iron, also known as nodular cast iron, features spherical graphite inclusions that enhance its tensile strength and impact resistance, making it ideal for automotive and heavy-duty applications. Gray iron contains flake graphite, which provides excellent vibration damping and machinability but lower tensile strength compared to ductile iron. Both materials offer distinct microstructures and mechanical properties suited for varying industrial uses.

Composition Differences Between Ductile and Gray Iron

Ductile iron contains higher levels of magnesium and nodulizing elements, which promote the formation of spherical graphite nodules, enhancing its toughness and ductility. Gray iron, in contrast, features flaky graphite within its microstructure due to lower magnesium content, resulting in increased brittleness and improved vibration damping. The carbon equivalent in ductile iron is balanced to maintain strength and ductility, while gray iron's composition favors wear resistance and thermal conductivity.

Microstructure Comparison: Ductile vs Gray Iron

Ductile iron features a microstructure with spherical graphite nodules that enhance its tensile strength and ductility, making it more resistant to impact and fatigue compared to gray iron. Gray iron contains flake-shaped graphite within a pearlitic or ferritic matrix, which creates stress concentration points that reduce its tensile strength and increase brittleness. The nodular graphite structure in ductile iron allows for improved machinability and toughness, whereas the flaky graphite in gray iron leads to better vibration damping but lower fracture resistance.

Mechanical Properties: Strength and Ductility

Ductile iron exhibits superior mechanical properties compared to gray iron, with tensile strength typically ranging from 60,000 to 100,000 psi, whereas gray iron averages 20,000 to 40,000 psi. The nodular graphite structure in ductile iron enhances ductility, allowing elongation percentages of 10-30%, while gray iron's flake graphite causes brittleness and elongation below 1%. These characteristics make ductile iron preferable for applications requiring high strength and toughness, while gray iron suits uses where vibration damping is essential.

Wear Resistance and Durability

Ductile iron exhibits superior wear resistance and durability compared to gray iron due to its spheroidal graphite microstructure, which enhances toughness and reduces crack propagation. The higher tensile strength and impact resistance of ductile iron make it ideal for components subjected to heavy loads and abrasive conditions. In contrast, gray iron's flake graphite structure provides good compressive strength but lower wear resistance, limiting its durability in high-stress applications.

Applications of Ductile Iron in Industry

Ductile iron is extensively used in industries requiring high tensile strength and impact resistance, such as automotive components, pipe and fittings for water and sewage systems, and heavy-duty machinery parts. Its superior ductility and fatigue resistance make it ideal for manufacturing crankshafts, gears, and agricultural equipment where durability under dynamic stress is essential. Compared to gray iron, ductile iron offers enhanced toughness, enabling broader applications in infrastructure and industrial machinery.

Uses of Gray Iron in Manufacturing

Gray iron is widely used in manufacturing due to its excellent castability, vibration damping properties, and good machinability, making it ideal for engine blocks, pipes, and automotive brake discs. Its graphite microstructure provides thermal conductivity and wear resistance, which benefits applications requiring high durability and heat dissipation. Gray iron is preferable for large, complex-shaped components where strength is moderate but cost efficiency and dimensional stability are critical.

Machinability and Castability

Ductile iron offers superior machinability due to its nodular graphite structure, which reduces tool wear and allows for higher cutting speeds compared to gray iron's flake graphite form. Castability of gray iron is generally better because its lower melting point and higher fluidity enable easier mold filling and finer detail reproduction. While ductile iron requires precise control during casting to maintain mechanical properties, gray iron remains preferred for complex shapes where ease of casting and cost-efficiency are prioritized.

Cost Analysis: Ductile Iron vs Gray Iron

Ductile iron typically incurs higher production costs than gray iron due to its alloying elements and heat treatment processes, which enhance strength and ductility. Gray iron offers a cost-effective solution for applications with lower mechanical demands, benefiting from simpler casting methods and cheaper raw materials. Selecting between ductile iron and gray iron depends on balancing budget constraints with performance requirements in industrial projects.

Selecting the Right Iron for Your Project

Ductile iron offers superior strength, impact resistance, and ductility due to its nodular graphite structure, making it ideal for high-stress applications like automotive components and pipelines. Gray iron, characterized by its flake graphite, excels in vibration damping and machinability, which suits engine blocks and machine bases where thermal conductivity and wear resistance are critical. Evaluating factors such as load requirements, environmental conditions, and mechanical properties ensures optimal selection between ductile and gray iron for project-specific performance.

Ductile Iron vs Gray Iron Infographic

materialdif.com

materialdif.com