Yield strength defines the maximum stress a metal can withstand without permanent deformation, whereas tensile strength represents the maximum stress a metal can endure before failure or fracture. Understanding the difference between yield strength and tensile strength is crucial for selecting metals that require both durability and flexibility in engineering applications. Engineers prioritize yield strength for structural stability and tensile strength for maximum load capacity under extreme conditions.

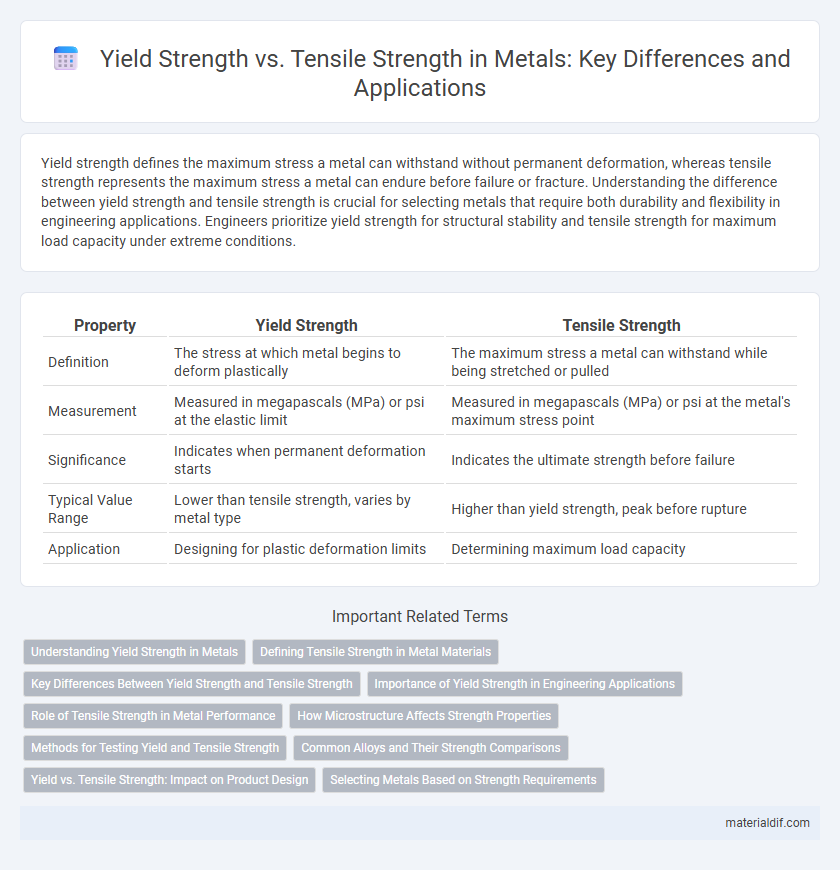

Table of Comparison

| Property | Yield Strength | Tensile Strength |

|---|---|---|

| Definition | The stress at which metal begins to deform plastically | The maximum stress a metal can withstand while being stretched or pulled |

| Measurement | Measured in megapascals (MPa) or psi at the elastic limit | Measured in megapascals (MPa) or psi at the metal's maximum stress point |

| Significance | Indicates when permanent deformation starts | Indicates the ultimate strength before failure |

| Typical Value Range | Lower than tensile strength, varies by metal type | Higher than yield strength, peak before rupture |

| Application | Designing for plastic deformation limits | Determining maximum load capacity |

Understanding Yield Strength in Metals

Yield strength in metals defines the stress level at which a material begins to deform plastically, marking the transition from elastic behavior to permanent deformation. It is a crucial parameter for engineers to predict when a metal will undergo irreversible changes under applied loads, ensuring structural integrity in applications like construction and manufacturing. Yield strength differs from tensile strength, which measures the maximum stress a material can withstand before fracture, emphasizing the importance of selecting metals based on their yield strength for safety-critical designs.

Defining Tensile Strength in Metal Materials

Tensile strength in metal materials refers to the maximum stress that a metal can withstand while being stretched or pulled before breaking. It represents the peak loading capacity during a tensile test and is a critical factor in determining metal performance in structural applications. High tensile strength typically indicates a metal's ability to resist deformation and failure under extreme forces.

Key Differences Between Yield Strength and Tensile Strength

Yield strength measures the maximum stress a metal can withstand without permanent deformation, while tensile strength indicates the maximum stress before fracture. Yield strength is critical for understanding the elastic limit, whereas tensile strength defines the ultimate load-bearing capacity. Differences in these properties determine suitability for applications requiring either elasticity or maximum durability.

Importance of Yield Strength in Engineering Applications

Yield strength is a critical mechanical property indicating the maximum stress a metal can withstand without permanent deformation, essential for ensuring safety and structural integrity in engineering applications. It determines the load capacity of materials in construction, automotive, and aerospace industries, preventing failure under operational stresses. Tensile strength measures the maximum stress before fracture, but the yield strength is more crucial for designing components that must maintain shape and function under everyday loads.

Role of Tensile Strength in Metal Performance

Tensile strength measures the maximum stress a metal can withstand while being stretched or pulled before breaking, playing a critical role in determining its overall durability and load-bearing capacity. High tensile strength indicates resistance to fracture under tension, making metals suitable for structural applications requiring reliability under dynamic or heavy loads. This property is essential for materials used in construction, automotive, and aerospace industries where failure under tensile stress can lead to catastrophic consequences.

How Microstructure Affects Strength Properties

Microstructure significantly influences yield strength and tensile strength in metals by dictating dislocation movement and grain boundary interactions. Fine-grained structures increase strength by providing more grain boundaries that impede dislocation motion, enhancing both yield and tensile strength. Phase distribution, precipitate formation, and defect density further alter mechanical properties by modifying the metal's resistance to deformation and fracture.

Methods for Testing Yield and Tensile Strength

Methods for testing yield strength typically involve applying a controlled load to a metal specimen using a universal testing machine until it reaches the proportional limit, marked by the onset of plastic deformation. Tensile strength is measured by pulling the specimen until fracture, recording the maximum stress endured during the test. Both tests rely on standard procedures such as ASTM E8/E8M, ensuring consistent and precise measurement of mechanical properties for metals.

Common Alloys and Their Strength Comparisons

Common metal alloys vary significantly in yield strength and tensile strength, with steel alloys typically exhibiting yield strengths from 250 to 1000 MPa and tensile strengths reaching up to 1600 MPa. Aluminum alloys generally have lower yield strengths, around 50 to 400 MPa, but maintain a good balance of toughness and ductility, while titanium alloys offer high yield strengths between 600 and 1200 MPa combined with excellent tensile strength up to 1400 MPa. Comparing these values aids in selecting alloys for applications demanding specific mechanical performance, such as aerospace, automotive, and structural engineering.

Yield vs. Tensile Strength: Impact on Product Design

Yield strength defines the maximum stress a metal can withstand without permanent deformation, serving as a critical parameter for ensuring structural integrity under load. Tensile strength, representing the maximum stress before fracture, dictates the ultimate limit of material performance. Understanding the balance between yield and tensile strength is essential for optimizing product design, ensuring safety margins, durability, and cost-effectiveness in metal component applications.

Selecting Metals Based on Strength Requirements

Yield strength defines the stress at which a metal begins to deform plastically, indicating its ability to withstand permanent shape changes. Tensile strength measures the maximum stress a metal can endure before failure, reflecting its ultimate load-bearing capacity. Selecting metals based on yield and tensile strength ensures optimal performance in applications requiring specific strength criteria and resistance to deformation or fracture.

Yield Strength vs Tensile Strength Infographic

materialdif.com

materialdif.com