Electropolished metal surfaces offer a smoother, shinier finish by removing a thin layer of material, enhancing corrosion resistance and reducing surface roughness compared to passivated metals. Passivation involves chemically treating the metal to create a protective oxide layer that prevents rust and corrosion without altering the surface's texture. Choosing between electropolished and passivated metals depends on the desired aesthetic finish and specific corrosion resistance requirements in industrial applications.

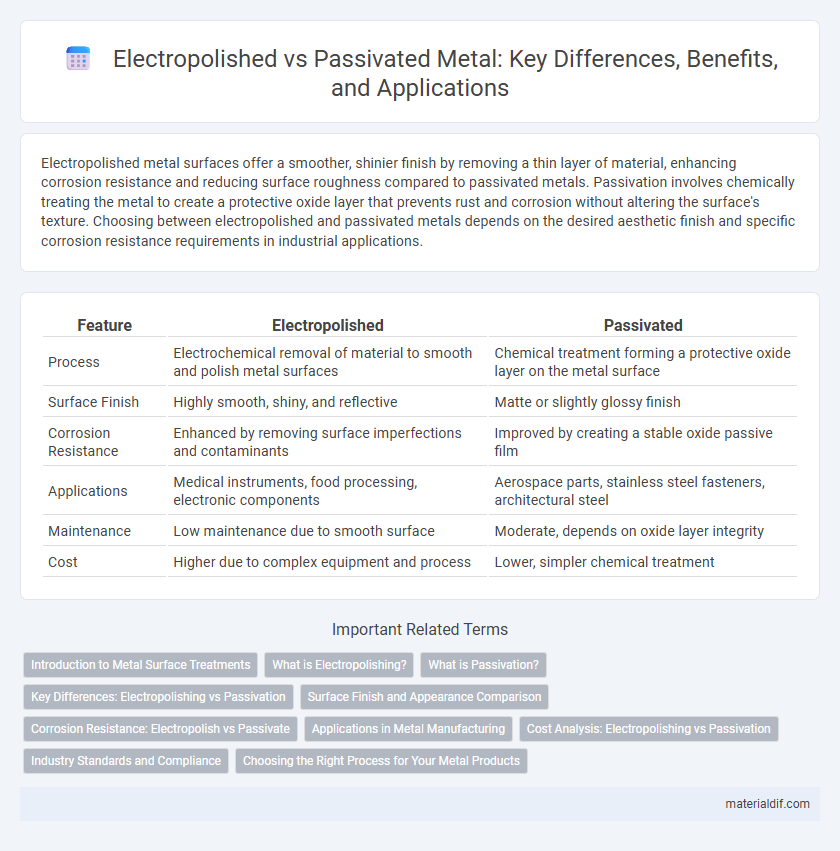

Table of Comparison

| Feature | Electropolished | Passivated |

|---|---|---|

| Process | Electrochemical removal of material to smooth and polish metal surfaces | Chemical treatment forming a protective oxide layer on the metal surface |

| Surface Finish | Highly smooth, shiny, and reflective | Matte or slightly glossy finish |

| Corrosion Resistance | Enhanced by removing surface imperfections and contaminants | Improved by creating a stable oxide passive film |

| Applications | Medical instruments, food processing, electronic components | Aerospace parts, stainless steel fasteners, architectural steel |

| Maintenance | Low maintenance due to smooth surface | Moderate, depends on oxide layer integrity |

| Cost | Higher due to complex equipment and process | Lower, simpler chemical treatment |

Introduction to Metal Surface Treatments

Electropolished surfaces exhibit enhanced corrosion resistance and a smoother finish by removing microscopic peaks through an electrochemical process, while passivated metals develop a protective oxide layer that prevents oxidation and rust. Both treatments significantly increase the durability and lifespan of stainless steel and other alloys used in critical applications such as medical devices and aerospace components. Choosing between electropolishing and passivation depends on the required surface smoothness, microbial resistance, and environmental exposure.

What is Electropolishing?

Electropolishing is an electrochemical process that removes a thin layer of metal from the surface to enhance smoothness and corrosion resistance. It produces a bright, reflective finish by eliminating microscopic peaks and valleys, reducing surface roughness and contaminants. This technique improves metal durability and hygiene, making it ideal for stainless steel in medical and food processing industries.

What is Passivation?

Passivation is a chemical treatment process that enhances the corrosion resistance of metal surfaces, particularly stainless steel, by creating a thin, inert oxide layer. This protective oxide film prevents oxidation and rust formation without altering the metal's appearance or dimensions. Passivation involves the removal of free iron and contaminants, improving metal durability and performance in corrosive environments.

Key Differences: Electropolishing vs Passivation

Electropolishing enhances metal surfaces by removing a thin layer of material through an electrochemical process, resulting in a smooth, shiny finish that improves corrosion resistance and cleanliness. Passivation, on the other hand, involves treating the metal with an acid solution to form a thin, protective oxide layer that prevents rust and contamination. Key differences include electropolishing improving surface texture and brightness, while passivation primarily focuses on strengthening the metal's natural oxide layer for corrosion protection.

Surface Finish and Appearance Comparison

Electropolished surfaces exhibit a smooth, mirror-like finish by removing microscopic peaks and leaving a uniform texture, enhancing corrosion resistance and aesthetic appeal. Passivated finishes, achieved through chemical treatment, maintain the metal's natural matte appearance while forming a protective oxide layer that prevents rust. Electropolishing results in a shinier, more reflective surface, whereas passivation prioritizes durability with a subtle, less glossy look.

Corrosion Resistance: Electropolish vs Passivate

Electropolished metals exhibit superior corrosion resistance due to their smooth, oxide-free surface that reduces surface defects and contaminants. Passivated metals rely on the formation of a thin oxide layer that protects against corrosion but may retain microscopic irregularities prone to localized attack. Electropolishing enhances corrosion resistance more effectively by creating a uniform, polished surface that minimizes sites for corrosive agents to initiate damage.

Applications in Metal Manufacturing

Electropolished surfaces enhance corrosion resistance and cleanability, making them ideal for medical devices, food processing equipment, and semiconductor manufacturing. Passivated metals, treated with acid solutions to form a protective oxide layer, are widely used in automotive parts, aerospace components, and architectural structures for improved durability and oxidation resistance. Both treatments optimize metal performance but are selected based on specific application requirements, such as surface finish precision and environmental exposure.

Cost Analysis: Electropolishing vs Passivation

Electropolishing typically incurs higher initial costs due to specialized equipment and chemical requirements but offers a more uniform surface finish that can reduce long-term maintenance expenses. Passivation is generally less expensive upfront, utilizing simpler acid treatments, but may require more frequent reprocessing to maintain corrosion resistance in demanding environments. Cost analysis must weigh electropolishing's durability and performance benefits against passivation's lower immediate expenditure, especially for high-precision or critical applications.

Industry Standards and Compliance

Electropolished metals offer a smooth, contamination-free surface that meets stringent ASTM B912 and AMS 2700 industry standards, enhancing corrosion resistance and cleanliness critical in aerospace and pharmaceutical applications. Passivated metals, treated to form a protective oxide layer, comply with ASTM A967 and ISO 14644-1, ensuring superior resistance in chemical processing and food-grade environments. Choosing between electropolishing and passivation depends on regulatory compliance requirements and the specific industry standards governing surface finish and corrosion protection.

Choosing the Right Process for Your Metal Products

Selecting between electropolished and passivated finishes depends on the specific metal application and required corrosion resistance. Electropolishing smooths microscopically rough surfaces by removing material, enhancing corrosion resistance and cleanliness, ideal for medical and food processing equipment. Passivation chemically removes free iron from the surface, forming a thin oxide layer that protects stainless steel from oxidation, best suited for architectural and automotive metal components.

Electropolished vs Passivated Infographic

materialdif.com

materialdif.com