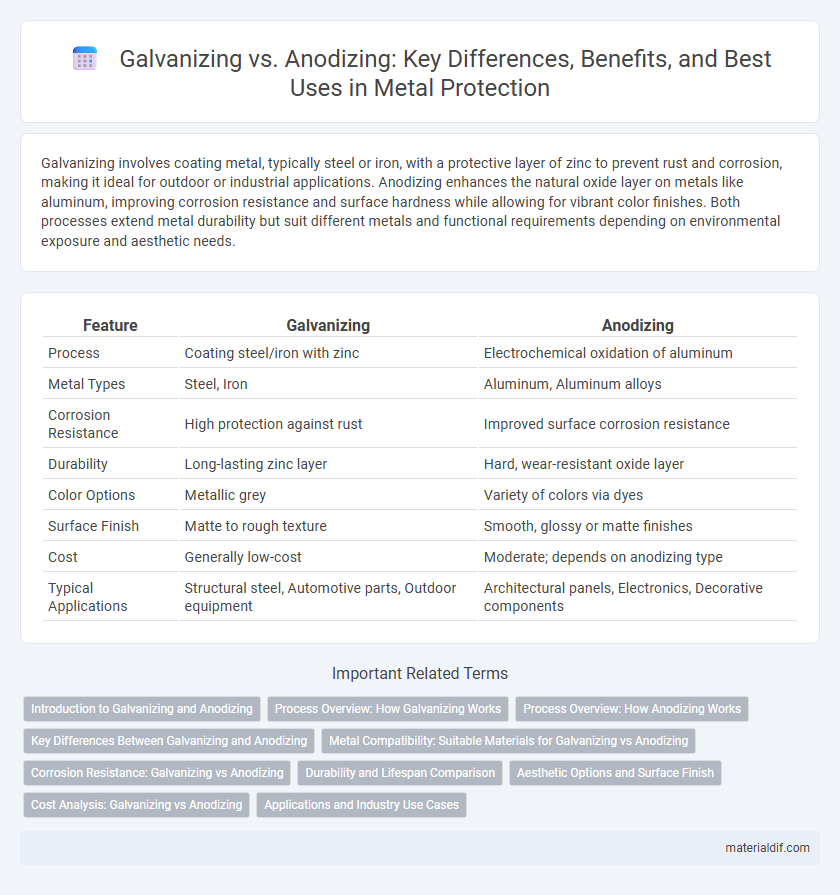

Galvanizing involves coating metal, typically steel or iron, with a protective layer of zinc to prevent rust and corrosion, making it ideal for outdoor or industrial applications. Anodizing enhances the natural oxide layer on metals like aluminum, improving corrosion resistance and surface hardness while allowing for vibrant color finishes. Both processes extend metal durability but suit different metals and functional requirements depending on environmental exposure and aesthetic needs.

Table of Comparison

| Feature | Galvanizing | Anodizing |

|---|---|---|

| Process | Coating steel/iron with zinc | Electrochemical oxidation of aluminum |

| Metal Types | Steel, Iron | Aluminum, Aluminum alloys |

| Corrosion Resistance | High protection against rust | Improved surface corrosion resistance |

| Durability | Long-lasting zinc layer | Hard, wear-resistant oxide layer |

| Color Options | Metallic grey | Variety of colors via dyes |

| Surface Finish | Matte to rough texture | Smooth, glossy or matte finishes |

| Cost | Generally low-cost | Moderate; depends on anodizing type |

| Typical Applications | Structural steel, Automotive parts, Outdoor equipment | Architectural panels, Electronics, Decorative components |

Introduction to Galvanizing and Anodizing

Galvanizing involves coating steel or iron with a layer of zinc to prevent corrosion, commonly using hot-dip or electro-galvanizing methods for enhanced durability. Anodizing is an electrochemical process that thickens the natural oxide layer on aluminum surfaces, improving corrosion resistance and surface hardness while allowing for color customization. Both processes extend metal lifespan and protect against environmental damage but apply to different base metals and employ distinct protective mechanisms.

Process Overview: How Galvanizing Works

Galvanizing involves coating steel or iron with a layer of zinc to protect against corrosion by immersing the metal in a molten zinc bath at approximately 450degC (842degF). The zinc layer acts as a sacrificial anode, preventing rust even if the coating is scratched or damaged. This hot-dip galvanizing process creates a metallurgical bond between zinc and the base metal, ensuring long-lasting durability and corrosion resistance.

Process Overview: How Anodizing Works

Anodizing is an electrochemical process that increases the thickness of the natural oxide layer on the surface of metal parts, primarily aluminum. During anodizing, the metal acts as the anode in an electrolytic cell, where immersion in an acid electrolyte and application of an electric current induce oxide layer growth. This thicker oxide layer enhances corrosion resistance, surface hardness, and provides better adhesion for paints or dyes.

Key Differences Between Galvanizing and Anodizing

Galvanizing involves coating steel or iron with a protective layer of zinc to prevent corrosion, while anodizing enhances the natural oxide layer on aluminum to increase corrosion resistance and surface hardness. Galvanizing typically adds a thicker, more durable coating suitable for outdoor and harsh environments, whereas anodizing results in a thinner, more decorative, and corrosion-resistant finish ideal for aluminum products. The key differences lie in the metals treated, the coating materials used, and the protective mechanisms each process provides.

Metal Compatibility: Suitable Materials for Galvanizing vs Anodizing

Galvanizing primarily suits ferrous metals such as steel and iron, providing a robust zinc coating to prevent corrosion. Anodizing is compatible mainly with aluminum and its alloys, enhancing corrosion resistance and surface hardness through controlled oxide layer formation. Steel and iron cannot be effectively anodized, while aluminum does not benefit from galvanizing due to poor zinc adhesion.

Corrosion Resistance: Galvanizing vs Anodizing

Galvanizing offers superior corrosion resistance by coating steel or iron with a thick layer of zinc, which acts as a sacrificial barrier, preventing rust even if the coating is scratched. Anodizing enhances corrosion resistance by creating a dense, stable oxide layer on aluminum surfaces, improving protection against oxidation and wear, especially in marine and industrial environments. While galvanizing is ideal for ferrous metals exposed to harsh conditions, anodizing is preferred for aluminum components requiring lightweight and durable corrosion protection.

Durability and Lifespan Comparison

Galvanizing involves coating steel with a layer of zinc to provide long-lasting corrosion resistance, often extending the metal's lifespan by decades in outdoor environments. Anodizing, primarily used for aluminum, enhances surface hardness and resistance to wear while improving corrosion resistance through an oxide layer, but generally offers a shorter lifespan when exposed to harsh conditions. While galvanized steel excels in durability against rust and physical damage, anodized aluminum provides a more aesthetically appealing finish with moderate protection, making galvanizing more suitable for heavy-duty applications requiring extended longevity.

Aesthetic Options and Surface Finish

Galvanizing produces a thick, protective zinc coating that results in a matte, rough texture primarily used for corrosion resistance, with limited aesthetic variations. Anodizing enhances aluminum surfaces by creating a durable oxide layer that offers a smooth finish available in a wide range of vibrant colors and patterns. The choice between galvanizing and anodizing depends on desired surface appearance, with anodizing providing superior aesthetic versatility and a polished look.

Cost Analysis: Galvanizing vs Anodizing

Galvanizing typically offers a lower initial cost compared to anodizing, making it more cost-effective for large-scale steel applications requiring robust corrosion resistance. Anodizing, while more expensive upfront, provides enhanced durability and aesthetic appeal for aluminum components, potentially reducing long-term maintenance expenses. Cost analysis should consider material type, project scale, lifecycle requirements, and desired finish quality to determine the most economical surface treatment.

Applications and Industry Use Cases

Galvanizing is predominantly applied in construction, automotive, and marine industries where corrosion resistance of steel and iron components is critical for structural integrity and longevity. Anodizing is widely used in aerospace, electronics, and architectural sectors to enhance aluminum's surface durability, wear resistance, and aesthetic appeal. Both processes address metal protection but serve distinct industrial needs due to their differing chemical treatments and resulting material properties.

Galvanizing vs Anodizing Infographic

materialdif.com

materialdif.com