Powder metallurgy involves producing metal parts by compacting fine metal powders and then heating them below the melting point to create solid structures. Sintered metal refers specifically to the outcome of this process, where individual metal particles are fused together during sintering to achieve desired mechanical properties. This technique enhances material utilization, reduces waste, and allows complex shapes that are difficult to achieve with traditional metalworking methods.

Table of Comparison

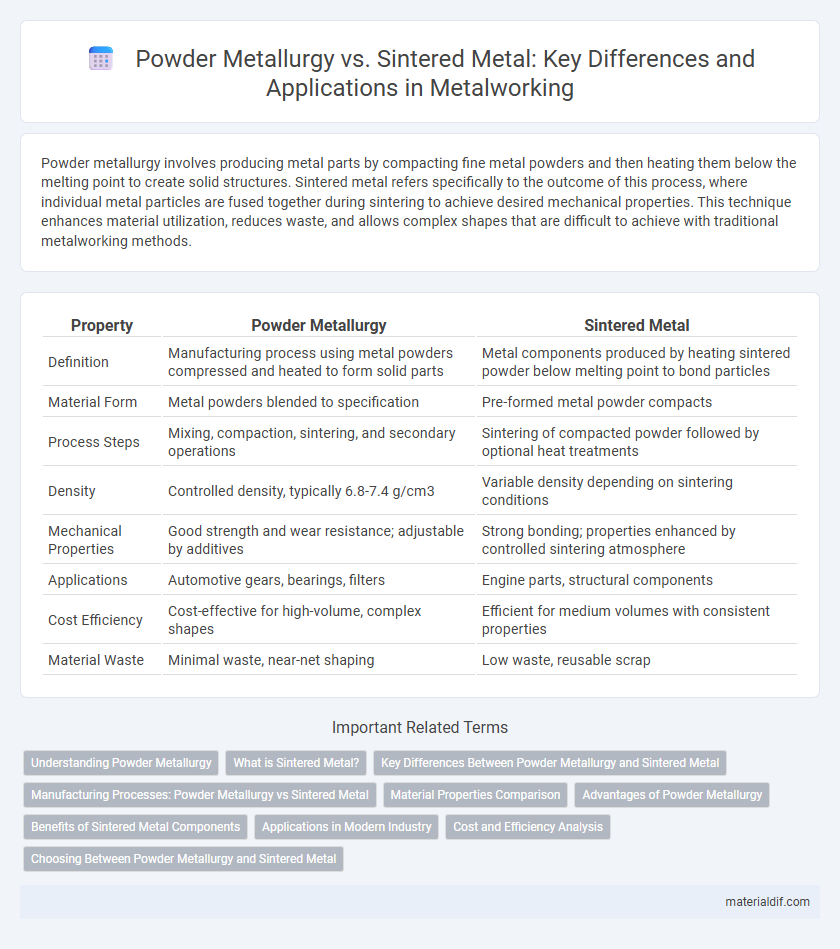

| Property | Powder Metallurgy | Sintered Metal |

|---|---|---|

| Definition | Manufacturing process using metal powders compressed and heated to form solid parts | Metal components produced by heating sintered powder below melting point to bond particles |

| Material Form | Metal powders blended to specification | Pre-formed metal powder compacts |

| Process Steps | Mixing, compaction, sintering, and secondary operations | Sintering of compacted powder followed by optional heat treatments |

| Density | Controlled density, typically 6.8-7.4 g/cm3 | Variable density depending on sintering conditions |

| Mechanical Properties | Good strength and wear resistance; adjustable by additives | Strong bonding; properties enhanced by controlled sintering atmosphere |

| Applications | Automotive gears, bearings, filters | Engine parts, structural components |

| Cost Efficiency | Cost-effective for high-volume, complex shapes | Efficient for medium volumes with consistent properties |

| Material Waste | Minimal waste, near-net shaping | Low waste, reusable scrap |

Understanding Powder Metallurgy

Powder metallurgy involves compressing metal powders into desired shapes followed by sintering, a heat treatment process that bonds particles without melting. This technique allows precise control over material composition and porosity, enhancing mechanical properties like wear resistance and strength. Understanding powder metallurgy is crucial for optimizing sintered metal parts used in automotive, aerospace, and industrial applications.

What is Sintered Metal?

Sintered metal is a product of powder metallurgy created by compacting metal powders and heating them below their melting point to bond particles without liquefaction. This process enhances material properties such as strength, density, and wear resistance, making sintered metal ideal for precise and durable components in automotive and aerospace industries. Sintered metal manufacturing allows complex shapes and reduces material waste compared to traditional metalworking methods.

Key Differences Between Powder Metallurgy and Sintered Metal

Powder metallurgy is a manufacturing process that involves blending fine metal powders, compacting them into a desired shape, and heating them to form a solid piece, whereas sintered metal specifically refers to the product created after the powders are heated below their melting point to bond. Key differences include that powder metallurgy encompasses the entire process from powder production to final part, while sintered metal focuses solely on the stage where the compacted powders are fused. Powder metallurgy enables precise control of material properties and complex geometries, whereas sintered metal products benefit from enhanced mechanical strength and density achieved through the sintering phase.

Manufacturing Processes: Powder Metallurgy vs Sintered Metal

Powder metallurgy involves blending fine metal powders, compacting them into desired shapes, and heating below melting point to bond particles through diffusion. Sintered metal refers to the end product obtained from this process, where the compacted powder is heated to enhance strength and density without melting. Both techniques allow precise control over material properties, reduce waste, and enable manufacturing of complex geometries not feasible with traditional casting or machining.

Material Properties Comparison

Powder metallurgy produces materials with uniform microstructures, resulting in controlled porosity and enhanced mechanical properties like strength and wear resistance, whereas sintered metal often exhibits variable density and grain growth affecting toughness and ductility. Sintering temperature and atmosphere critically influence the bonded particle interfaces, leading to differences in hardness and corrosion resistance compared to traditional powder metallurgy components. Optimizing particle size distribution and compaction pressure in powder metallurgy enables tailored magnetic, thermal, and fatigue properties unmatched by conventional sintered metals.

Advantages of Powder Metallurgy

Powder metallurgy offers precise control over material composition and microstructure, resulting in superior mechanical properties and uniformity compared to sintered metal. This process enables the production of complex shapes with minimal material waste and reduced machining costs. High dimensional accuracy and enhanced material utilization make powder metallurgy a cost-effective and efficient method for manufacturing high-performance metal components.

Benefits of Sintered Metal Components

Sintered metal components offer superior uniformity and strength due to the controlled heating process that fuses metal powders without melting, enhancing mechanical properties and dimensional accuracy. These components provide excellent wear resistance and dimensional stability, making them ideal for high-performance applications such as automotive parts and industrial machinery. Sintering also reduces material waste compared to traditional machining, promoting cost efficiency and sustainability in metal component manufacturing.

Applications in Modern Industry

Powder metallurgy produces components with complex geometries and precise tolerances, making it ideal for automotive parts like gears and engine components requiring high strength and durability. Sintered metal finds extensive use in manufacturing porous materials for filtration, bearings, and self-lubricating parts in aerospace and industrial machinery due to its controlled porosity and wear resistance. Both technologies enable cost-effective mass production while meeting stringent performance standards in sectors including electronics, healthcare, and defense.

Cost and Efficiency Analysis

Powder metallurgy offers significant cost advantages through material savings and near-net shape manufacturing, reducing waste and machining expenses compared to traditional sintered metal processes. Sintered metal techniques sometimes require higher energy inputs and longer processing times, impacting overall efficiency and increasing production costs. Evaluating both methods reveals powder metallurgy as a more economical choice for high-volume applications where precision and low-cost production are critical.

Choosing Between Powder Metallurgy and Sintered Metal

Choosing between powder metallurgy and sintered metal depends on the application requirements such as component complexity, mechanical properties, and production volume. Powder metallurgy offers precise control over material composition and minimal waste, ideal for high-volume manufacturing with consistent quality. Sintered metal enhances density and strength through controlled heating processes, making it suitable for parts requiring superior mechanical performance and wear resistance.

Powder Metallurgy vs Sintered Metal Infographic

materialdif.com

materialdif.com