Aluminum offers lightweight properties and excellent corrosion resistance, making it ideal for applications requiring ease of fabrication and cost-effectiveness. Titanium provides superior strength-to-weight ratio and exceptional resistance to high temperatures and corrosion, favored in aerospace and medical industries. Comparing aluminum and titanium involves balancing factors such as mechanical strength, weight, corrosion resistance, and overall cost efficiency.

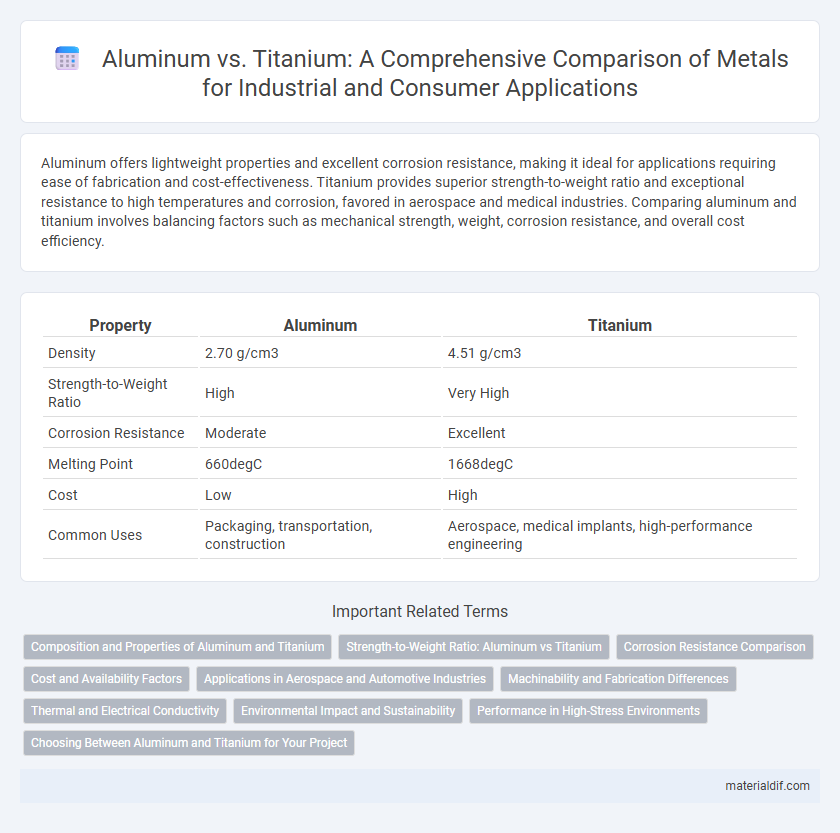

Table of Comparison

| Property | Aluminum | Titanium |

|---|---|---|

| Density | 2.70 g/cm3 | 4.51 g/cm3 |

| Strength-to-Weight Ratio | High | Very High |

| Corrosion Resistance | Moderate | Excellent |

| Melting Point | 660degC | 1668degC |

| Cost | Low | High |

| Common Uses | Packaging, transportation, construction | Aerospace, medical implants, high-performance engineering |

Composition and Properties of Aluminum and Titanium

Aluminum is a lightweight metal primarily composed of 92-99% aluminum with small amounts of copper, magnesium, and silicon, offering excellent corrosion resistance and high thermal conductivity. Titanium consists mainly of 90-98% titanium alloyed with aluminum, vanadium, and iron, making it stronger and more resistant to extreme temperatures than aluminum. While aluminum is favored for its low density and good electrical conductivity, titanium provides superior strength-to-weight ratio and exceptional corrosion resistance in harsh environments.

Strength-to-Weight Ratio: Aluminum vs Titanium

Titanium exhibits a superior strength-to-weight ratio compared to aluminum, making it a preferred choice for applications requiring high strength and low weight, such as aerospace and military components. While aluminum is lighter and more cost-effective, titanium's strength allows for thinner, lighter structures without compromising durability. This advantage results in enhanced performance and fuel efficiency in industries where weight reduction is critical.

Corrosion Resistance Comparison

Titanium exhibits superior corrosion resistance compared to aluminum, especially in harsh environments such as marine and acidic conditions, due to its stable oxide film that prevents oxidation. Aluminum forms a protective oxide layer as well, but it is more susceptible to pitting and galvanic corrosion in chloride-rich environments. This enhanced resistance makes titanium preferable for applications requiring long-term durability against corrosive elements.

Cost and Availability Factors

Aluminum is significantly more cost-effective than titanium due to its abundant availability and lower extraction and processing expenses. Titanium, despite its superior strength-to-weight ratio and corrosion resistance, remains costly because of limited natural deposits and complex refining methods. The widespread availability of aluminum makes it the preferred choice for applications requiring budget-friendly and large-scale metal use.

Applications in Aerospace and Automotive Industries

Aluminum's lightweight properties and corrosion resistance make it ideal for aircraft fuselage and automotive body panels, enhancing fuel efficiency and durability. Titanium offers superior strength-to-weight ratio and high-temperature resistance, critical for aerospace engine components and high-performance automotive parts. Both metals drive innovation in aerospace and automotive sectors, balancing weight reduction with structural integrity.

Machinability and Fabrication Differences

Aluminum offers superior machinability due to its lower hardness and density, enabling faster cutting speeds and reduced tool wear compared to titanium. Titanium's high strength-to-weight ratio results in tougher fabrication processes, requiring specialized tooling and slower machining to prevent work hardening and thermal damage. The choice between aluminum and titanium hinges on balancing ease of fabrication with performance demands, where aluminum excels in cost-effectiveness and machining efficiency, while titanium provides enhanced durability and corrosion resistance.

Thermal and Electrical Conductivity

Aluminum exhibits a thermal conductivity of approximately 237 W/m*K, significantly higher than titanium's 21.9 W/m*K, making aluminum more efficient for heat dissipation applications. In terms of electrical conductivity, aluminum ranks about 61% of copper, around 35 MS/m, whereas titanium has a much lower electrical conductivity of roughly 2.4 MS/m. These thermal and electrical properties result in aluminum being preferred in electrical wiring and heat exchangers, while titanium's lower conductivities suit it for structural components requiring strength and corrosion resistance.

Environmental Impact and Sustainability

Aluminum production requires significantly less energy compared to titanium, making it a more environmentally sustainable option in terms of carbon emissions and resource consumption. Titanium offers superior corrosion resistance and longevity, reducing the frequency of replacements and associated environmental costs over its lifecycle. Recycling rates for aluminum are notably higher, further enhancing its sustainability by minimizing mining impacts and energy use in material production.

Performance in High-Stress Environments

Titanium outperforms aluminum in high-stress environments due to its superior strength-to-weight ratio and exceptional corrosion resistance. Its ability to maintain structural integrity under extreme temperatures and mechanical loads makes it ideal for aerospace, military, and marine applications. Although aluminum offers lighter weight and cost advantages, titanium's durability and fatigue resistance provide unmatched reliability in critical, high-performance conditions.

Choosing Between Aluminum and Titanium for Your Project

Aluminum offers lightweight properties, excellent corrosion resistance, and cost-effectiveness, making it ideal for projects requiring budget-friendly material with moderate strength. Titanium boasts superior strength-to-weight ratio, exceptional corrosion resistance, and high durability, suitable for high-performance applications in aerospace, medical, and marine industries. Selecting between aluminum and titanium depends on balancing factors like budget constraints, strength requirements, and environmental exposure in your project.

Aluminum vs Titanium Infographic

materialdif.com

materialdif.com