Ductility refers to a metal's ability to be stretched into a wire without breaking, highlighting its tensile strength and elongation capacity. Malleability describes a metal's capacity to deform under compressive stress, allowing it to be hammered or rolled into thin sheets without cracking. These properties are critical in metalworking processes, influencing applications in manufacturing, construction, and engineering.

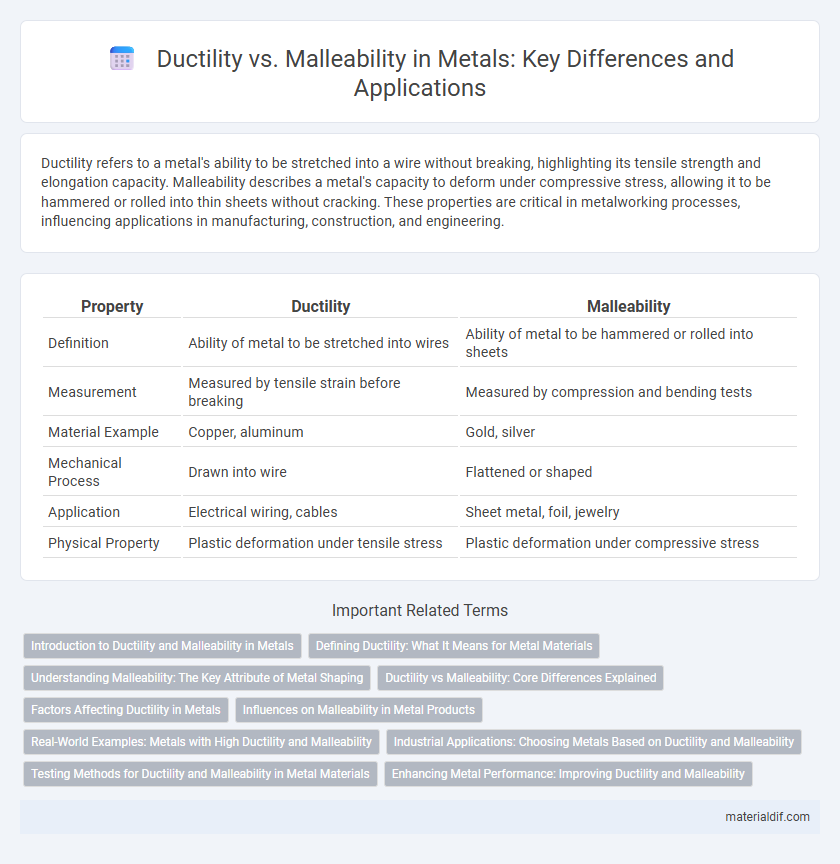

Table of Comparison

| Property | Ductility | Malleability |

|---|---|---|

| Definition | Ability of metal to be stretched into wires | Ability of metal to be hammered or rolled into sheets |

| Measurement | Measured by tensile strain before breaking | Measured by compression and bending tests |

| Material Example | Copper, aluminum | Gold, silver |

| Mechanical Process | Drawn into wire | Flattened or shaped |

| Application | Electrical wiring, cables | Sheet metal, foil, jewelry |

| Physical Property | Plastic deformation under tensile stress | Plastic deformation under compressive stress |

Introduction to Ductility and Malleability in Metals

Ductility in metals refers to their ability to undergo significant plastic deformation under tensile stress, allowing them to be stretched into wires without breaking. Malleability, on the other hand, describes the capacity of a metal to deform under compressive stress, enabling it to be hammered or rolled into thin sheets. Both properties are critical indicators of a metal's mechanical behavior and influence its suitability for various industrial applications.

Defining Ductility: What It Means for Metal Materials

Ductility in metal materials refers to the ability to undergo significant plastic deformation under tensile stress without fracturing, allowing metals like copper and aluminum to be drawn into thin wires. This property is critical for applications requiring extensive shaping while maintaining structural integrity. Unlike malleability, which relates to compressive stress and shaping by hammering or rolling, ductility specifically measures tensile elongation and flexibility in metals.

Understanding Malleability: The Key Attribute of Metal Shaping

Malleability defines a metal's ability to deform under compressive stress, enabling it to be hammered or rolled into thin sheets without fracturing. This property is distinct from ductility, which refers to a metal's capacity to stretch into wires under tensile stress. High malleability in metals such as gold, silver, and aluminum is crucial for manufacturing processes involving sheet metal fabrication and intricate shaping.

Ductility vs Malleability: Core Differences Explained

Ductility refers to a metal's ability to undergo significant plastic deformation before rupture, typically measured by its capacity to be stretched into wires without breaking. Malleability, on the other hand, describes how easily a metal can be hammered or rolled into thin sheets without cracking. While both properties indicate metal deformability, ductility emphasizes tensile deformation, and malleability focuses on compressive deformation.

Factors Affecting Ductility in Metals

Ductility in metals is primarily influenced by factors such as temperature, which increases atomic movement and allows metals to deform without breaking. The presence of impurities and alloying elements can obstruct dislocation motion, significantly reducing ductility. Crystal structure and grain size also play critical roles; smaller grains typically enhance ductility by providing more grain boundaries that impede crack propagation.

Influences on Malleability in Metal Products

Malleability in metal products is primarily influenced by the metal's crystal structure and temperature during processing, with face-centered cubic (FCC) metals like gold and aluminum exhibiting higher malleability due to their ability to deform without fracturing. Alloying elements can either enhance or reduce malleability by altering grain size and dislocation movement within the metal matrix. Cold working and heat treatment processes further impact malleability by modifying internal stresses and microstructural properties, optimizing the metal's capacity to be shaped under compressive forces.

Real-World Examples: Metals with High Ductility and Malleability

Copper exhibits high ductility, allowing it to be drawn into thin wires for electrical wiring, while gold demonstrates exceptional malleability, used extensively in intricate jewelry shaping. Aluminum combines moderate ductility and malleability, making it ideal for packaging materials like foil and cans. Steel alloys balance ductility and malleability to enable structural flexibility and formability in construction and automotive industries.

Industrial Applications: Choosing Metals Based on Ductility and Malleability

Industries select metals based on ductility for applications requiring wire or sheet metal fabrication, such as electrical wiring and automotive components. Malleability is prioritized in metal forming processes like stamping and rolling, essential in manufacturing structural elements and packaging materials. Understanding the balance between ductility and malleability ensures optimal material performance and cost-efficiency in industrial production.

Testing Methods for Ductility and Malleability in Metal Materials

Ductility in metals is commonly tested using tensile tests that measure the elongation and reduction in area before fracture, indicating the material's ability to deform under tensile stress. Malleability is assessed through compression or bending tests that evaluate how a metal withstands deformation without cracking under compressive forces. Both testing methods provide critical data on mechanical properties, guiding material selection for industrial applications where metal forming processes are involved.

Enhancing Metal Performance: Improving Ductility and Malleability

Enhancing metal performance involves optimizing both ductility and malleability to achieve superior mechanical properties, enabling metals to withstand deformation without fracture. Techniques such as alloying with elements like nickel or chromium and applying heat treatments can significantly improve ductility by increasing metal's ability to undergo tensile stress. Simultaneously, controlling grain size through thermomechanical processing enhances malleability, allowing metals to be shaped and formed efficiently without compromising structural integrity.

Ductility vs Malleability Infographic

materialdif.com

materialdif.com