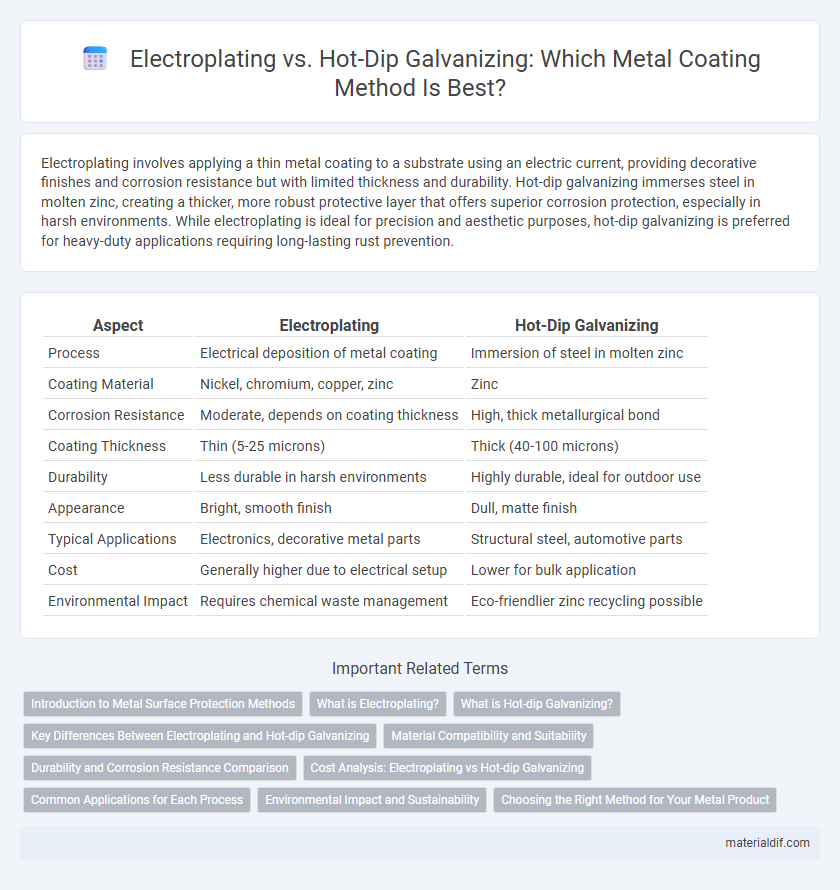

Electroplating involves applying a thin metal coating to a substrate using an electric current, providing decorative finishes and corrosion resistance but with limited thickness and durability. Hot-dip galvanizing immerses steel in molten zinc, creating a thicker, more robust protective layer that offers superior corrosion protection, especially in harsh environments. While electroplating is ideal for precision and aesthetic purposes, hot-dip galvanizing is preferred for heavy-duty applications requiring long-lasting rust prevention.

Table of Comparison

| Aspect | Electroplating | Hot-Dip Galvanizing |

|---|---|---|

| Process | Electrical deposition of metal coating | Immersion of steel in molten zinc |

| Coating Material | Nickel, chromium, copper, zinc | Zinc |

| Corrosion Resistance | Moderate, depends on coating thickness | High, thick metallurgical bond |

| Coating Thickness | Thin (5-25 microns) | Thick (40-100 microns) |

| Durability | Less durable in harsh environments | Highly durable, ideal for outdoor use |

| Appearance | Bright, smooth finish | Dull, matte finish |

| Typical Applications | Electronics, decorative metal parts | Structural steel, automotive parts |

| Cost | Generally higher due to electrical setup | Lower for bulk application |

| Environmental Impact | Requires chemical waste management | Eco-friendlier zinc recycling possible |

Introduction to Metal Surface Protection Methods

Electroplating and hot-dip galvanizing are essential metal surface protection methods designed to enhance corrosion resistance and extend the lifespan of metal components. Electroplating involves depositing a thin layer of metal, such as chrome or nickel, onto a substrate through an electrochemical process, resulting in a smooth, decorative, and protective finish. Hot-dip galvanizing, by immersing steel in molten zinc, forms a robust, zinc-iron alloy coating that offers superior durability and sacrificial protection against rust in harsh environments.

What is Electroplating?

Electroplating is a metal finishing process that uses electrical current to deposit a thin layer of metal, such as nickel, chromium, or gold, onto the surface of a substrate. This technique enhances corrosion resistance, improves aesthetic appeal, and increases surface hardness without significantly altering the dimensions of the base metal. Electroplating is widely used in industries like automotive, electronics, and jewelry for precise and uniform metal coatings.

What is Hot-dip Galvanizing?

Hot-dip galvanizing is a metal protection process that involves immersing steel or iron into molten zinc, creating a robust, corrosion-resistant coating. This method forms a metallurgical bond between the zinc and the base metal, providing superior durability and long-term rust prevention compared to surface-only coatings like electroplating. Commonly used in construction, automotive, and industrial applications, hot-dip galvanizing ensures enhanced longevity in harsh environments.

Key Differences Between Electroplating and Hot-dip Galvanizing

Electroplating deposits a thin layer of metal, commonly zinc or nickel, onto a substrate through an electrolytic process, enhancing corrosion resistance and appearance with precise thickness control. Hot-dip galvanizing involves immersing steel in molten zinc, forming a robust, metallurgically bonded coating that offers superior corrosion protection, especially in harsh environments. While electroplating provides a more decorative and uniform finish suitable for smaller or intricate parts, hot-dip galvanizing produces a thicker, more durable layer ideal for structural steel exposed to outdoor conditions.

Material Compatibility and Suitability

Electroplating offers precise control over coating thickness and is ideal for metals requiring decorative finishes or corrosion resistance on delicate components such as copper, brass, and steel. Hot-dip galvanizing provides a robust, thick zinc layer suitable for steel and iron structures exposed to harsh outdoor environments, enhancing durability and corrosion protection. Material compatibility hinges on the metal substrate's reactivity and intended use, with electroplating favored for intricate parts and galvanizing preferred for heavy-duty applications.

Durability and Corrosion Resistance Comparison

Electroplating provides a thin metal coating that enhances corrosion resistance but may wear off over time under harsh conditions, making it suitable for decorative or light-duty applications. Hot-dip galvanizing forms a thick, robust zinc layer that bonds metallurgically with the steel surface, offering superior durability and long-term corrosion protection in aggressive environments. The zinc coating in hot-dip galvanizing sacrificially protects the base metal even if scratched, significantly outperforming electroplated layers in resistance to rust and mechanical damage.

Cost Analysis: Electroplating vs Hot-dip Galvanizing

Electroplating generally incurs higher initial costs due to expensive equipment and specialized chemicals, making it less cost-effective for large-scale applications compared to hot-dip galvanizing. Hot-dip galvanizing offers lower overall expenses through bulk processing and longer-lasting coatings that reduce maintenance and replacement costs. For industrial-scale corrosion protection, hot-dip galvanizing typically provides a more economical solution over the product's lifecycle.

Common Applications for Each Process

Electroplating is commonly applied in electronics, automotive parts, and decorative metal items, providing a thin, uniform coating that enhances corrosion resistance and aesthetic appeal. Hot-dip galvanizing is widely used for structural steel components in construction, bridges, and outdoor frameworks due to its thick, durable zinc layer that offers robust protection against harsh environmental conditions. Both processes serve essential roles in metal preservation, with electroplating favored for precision and appearance, while hot-dip galvanizing excels in heavy-duty, long-term corrosion defense.

Environmental Impact and Sustainability

Electroplating involves the use of hazardous chemicals and generates toxic waste that requires careful disposal to prevent environmental contamination, raising concerns about sustainability in large-scale applications. Hot-dip galvanizing uses molten zinc to coat steel, providing long-lasting corrosion protection with minimal environmental pollutants and lower carbon footprint during production. The longer lifespan of hot-dip galvanized steel reduces the need for frequent reapplication and resource consumption, making it a more sustainable option for protecting metal surfaces.

Choosing the Right Method for Your Metal Product

Electroplating offers precise metal coating with enhanced aesthetic appeal and corrosion resistance, ideal for decorative or electronic components requiring thin, uniform layers. Hot-dip galvanizing provides thicker, durable zinc coatings optimal for structural steel exposed to harsh outdoor environments, ensuring long-lasting rust protection. Selecting the appropriate method depends on the metal product's application, environmental exposure, and desired coating thickness to balance cost-effectiveness with performance.

Electroplating vs Hot-dip Galvanizing Infographic

materialdif.com

materialdif.com