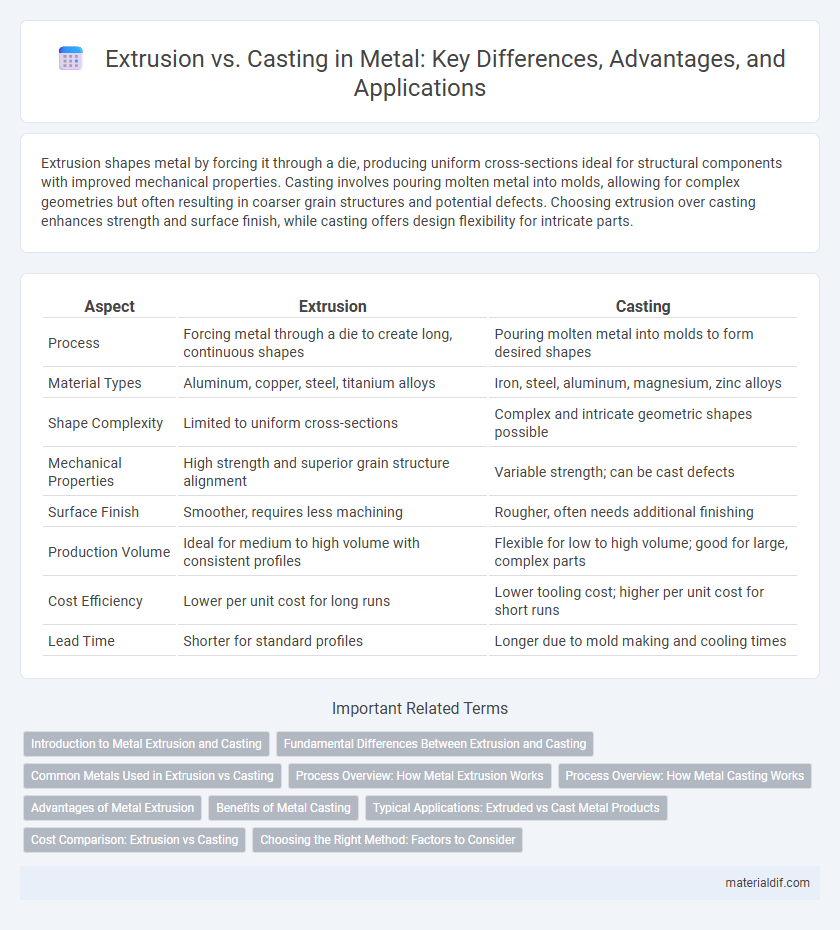

Extrusion shapes metal by forcing it through a die, producing uniform cross-sections ideal for structural components with improved mechanical properties. Casting involves pouring molten metal into molds, allowing for complex geometries but often resulting in coarser grain structures and potential defects. Choosing extrusion over casting enhances strength and surface finish, while casting offers design flexibility for intricate parts.

Table of Comparison

| Aspect | Extrusion | Casting |

|---|---|---|

| Process | Forcing metal through a die to create long, continuous shapes | Pouring molten metal into molds to form desired shapes |

| Material Types | Aluminum, copper, steel, titanium alloys | Iron, steel, aluminum, magnesium, zinc alloys |

| Shape Complexity | Limited to uniform cross-sections | Complex and intricate geometric shapes possible |

| Mechanical Properties | High strength and superior grain structure alignment | Variable strength; can be cast defects |

| Surface Finish | Smoother, requires less machining | Rougher, often needs additional finishing |

| Production Volume | Ideal for medium to high volume with consistent profiles | Flexible for low to high volume; good for large, complex parts |

| Cost Efficiency | Lower per unit cost for long runs | Lower tooling cost; higher per unit cost for short runs |

| Lead Time | Shorter for standard profiles | Longer due to mold making and cooling times |

Introduction to Metal Extrusion and Casting

Metal extrusion involves forcing heated metal through a die to create objects with a fixed cross-sectional profile, offering superior mechanical properties and surface finishes compared to casting. Casting entails pouring molten metal into molds, allowing complex shapes and large components to be produced efficiently but often with coarser grain structures and potential defects. Both methods are fundamental in metalworking, with extrusion favored for uniformity and strength, and casting preferred for design versatility and scale.

Fundamental Differences Between Extrusion and Casting

Extrusion involves forcing heated metal through a die to create objects with a fixed cross-sectional profile, offering precise control over shape and mechanical properties. Casting entails pouring molten metal into a mold to solidify, allowing complex geometries but often resulting in coarser microstructures and potential porosity. The fundamental difference lies in extrusion's continuous deformation process versus casting's solidification from the liquid state, impacting material strength and surface finish.

Common Metals Used in Extrusion vs Casting

Aluminum, copper, and magnesium alloys are common metals used in extrusion due to their excellent malleability and ability to form uniform cross-sections. Casting frequently utilizes iron, steel, and aluminum alloys because they can fill complex mold cavities and solidify into intricate shapes with good mechanical properties. The choice between extrusion and casting alloys depends on desired part geometry, mechanical performance, and production volume.

Process Overview: How Metal Extrusion Works

Metal extrusion involves forcing heated metal billets through a shaped die to produce continuous profiles with uniform cross-sections, allowing for complex geometries and precise dimensions. The process enhances material properties through directional grain flow and typically uses aluminum, copper, and steel alloys for structural applications. Extrusion offers superior surface finish and mechanical strength compared to casting, making it ideal for manufacturing lightweight, high-strength metal components.

Process Overview: How Metal Casting Works

Metal casting involves pouring molten metal into a mold cavity shaped like the desired part, where it cools and solidifies to form the final component. The process includes pattern creation, mold making, metal melting, pouring, cooling, and removal of the casting, allowing complex geometries and large sizes. Compared to extrusion, casting offers greater flexibility in shapes and is ideal for producing intricate and heavy-duty metal parts.

Advantages of Metal Extrusion

Metal extrusion offers precise control over cross-sectional shapes, enabling the production of complex profiles with uniform mechanical properties. The process enhances material strength through work hardening and grain refinement, resulting in improved durability and performance. Extruded metals also feature superior surface finish and dimensional accuracy, reducing the need for secondary machining operations.

Benefits of Metal Casting

Metal casting offers superior design flexibility, enabling the production of complex geometries and intricate shapes that are difficult or impossible to achieve with extrusion. Casting accommodates a wide range of metal alloys, allowing for optimized material properties tailored to specific applications. This process reduces material waste and can produce large-scale components with uniform mechanical properties and enhanced dimensional accuracy.

Typical Applications: Extruded vs Cast Metal Products

Extruded metal products are commonly used in applications requiring precise cross-sectional profiles and structural strength, such as automotive frames, aerospace components, and architectural window frames. Cast metal products are preferred for complex shapes with intricate details, such as engine blocks, pump housings, and valve bodies. The choice between extrusion and casting depends on factors like production volume, mechanical properties, and design complexity.

Cost Comparison: Extrusion vs Casting

Extrusion generally offers lower production costs for long, uniform metal profiles due to reduced material waste and faster cycle times compared to casting. Casting incurs higher expenses driven by complex molds, longer cooling periods, and post-processing requirements. For large-scale manufacturing, extrusion is more cost-effective, while casting suits intricate shapes despite its higher initial investment.

Choosing the Right Method: Factors to Consider

Selecting between extrusion and casting depends on factors like desired mechanical properties, production volume, and geometric complexity. Extrusion offers superior strength and surface finish for uniform cross-sections, ideal for high-volume runs, while casting allows for intricate shapes and thicker sections with lower tooling costs. Consider material type, tolerance requirements, and lead time to determine the most efficient and cost-effective metal forming method.

Extrusion vs Casting Infographic

materialdif.com

materialdif.com