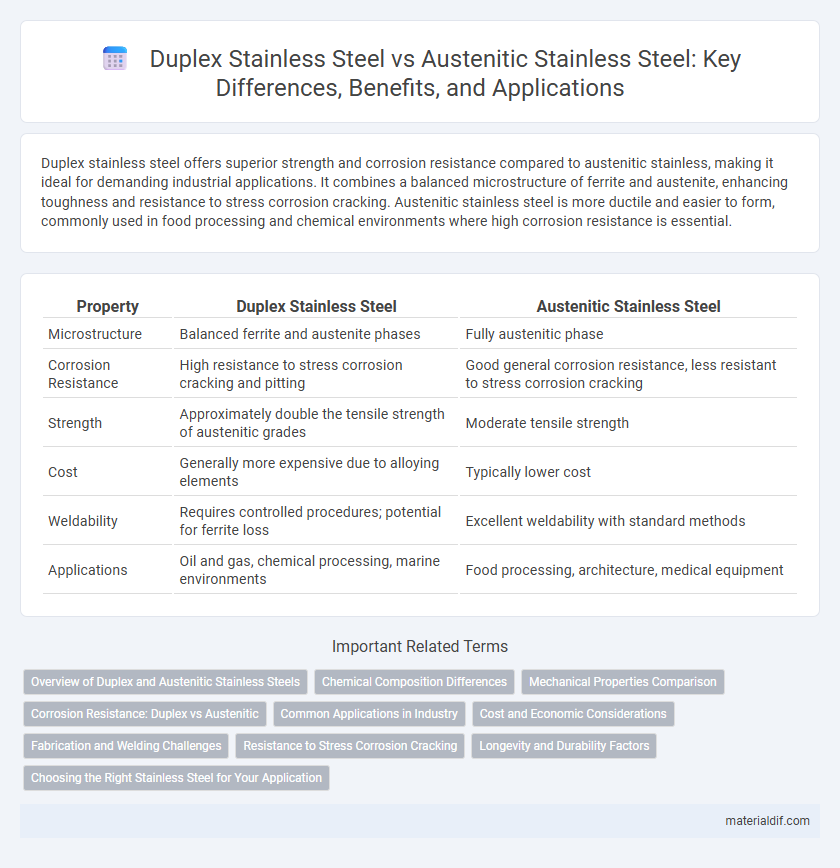

Duplex stainless steel offers superior strength and corrosion resistance compared to austenitic stainless, making it ideal for demanding industrial applications. It combines a balanced microstructure of ferrite and austenite, enhancing toughness and resistance to stress corrosion cracking. Austenitic stainless steel is more ductile and easier to form, commonly used in food processing and chemical environments where high corrosion resistance is essential.

Table of Comparison

| Property | Duplex Stainless Steel | Austenitic Stainless Steel |

|---|---|---|

| Microstructure | Balanced ferrite and austenite phases | Fully austenitic phase |

| Corrosion Resistance | High resistance to stress corrosion cracking and pitting | Good general corrosion resistance, less resistant to stress corrosion cracking |

| Strength | Approximately double the tensile strength of austenitic grades | Moderate tensile strength |

| Cost | Generally more expensive due to alloying elements | Typically lower cost |

| Weldability | Requires controlled procedures; potential for ferrite loss | Excellent weldability with standard methods |

| Applications | Oil and gas, chemical processing, marine environments | Food processing, architecture, medical equipment |

Overview of Duplex and Austenitic Stainless Steels

Duplex stainless steels combine austenitic and ferritic microstructures, offering superior strength and corrosion resistance compared to standard austenitic stainless steels, which are mainly composed of austenite. Austenitic stainless steels, characterized by high chromium and nickel content, provide excellent ductility, weldability, and resistance to oxidation. Duplex grades deliver enhanced performance in chloride-rich and aggressive environments due to their balanced microstructure and higher resistance to stress corrosion cracking.

Chemical Composition Differences

Duplex stainless steel combines approximately 22% chromium, 5-6% nickel, and 3% molybdenum, offering enhanced corrosion resistance and strength through its balanced ferritic and austenitic phases. Austenitic stainless steel typically contains 16-26% chromium and higher nickel content, around 8-10%, with little to no molybdenum, providing superior ductility and oxidation resistance. The distinct chemical composition of duplex stainless steels results in improved resistance to stress corrosion cracking compared to the higher nickel, lower molybdenum austenitic alloys.

Mechanical Properties Comparison

Duplex stainless steel exhibits higher tensile strength, typically ranging from 620 to 850 MPa, compared to austenitic stainless steel, which generally offers tensile strengths between 485 and 750 MPa. Duplex grades possess superior yield strength and better resistance to stress corrosion cracking due to their mixed microstructure of ferrite and austenite phases. Austenitic stainless steels provide higher ductility and better toughness at low temperatures but fall short of duplex stainless in hardness and fatigue resistance.

Corrosion Resistance: Duplex vs Austenitic

Duplex stainless steel offers superior corrosion resistance compared to austenitic stainless steel, particularly against stress corrosion cracking and chloride-induced corrosion. Its mixed microstructure of austenite and ferrite phases enhances resistance in aggressive environments such as marine and chemical processing applications. Austenitic stainless steel provides good general corrosion resistance but is more susceptible to localized corrosion and stress corrosion cracking under high chloride conditions.

Common Applications in Industry

Duplex stainless steel is widely used in chemical processing, oil and gas, and marine industries due to its superior corrosion resistance and high strength, especially in chloride-rich environments. Austenitic stainless steel dominates food processing, pharmaceutical, and architectural applications because of its excellent formability, weldability, and resistance to oxidation. Both materials are essential for industries requiring durability, corrosion resistance, and mechanical performance under varying environmental conditions.

Cost and Economic Considerations

Duplex stainless steel offers a cost-effective alternative to austenitic stainless steel due to its higher strength, which allows for thinner sections and material savings in construction and manufacturing. While the initial material cost of duplex stainless is typically higher, its superior corrosion resistance and reduced maintenance expenses often lead to lower total lifecycle costs. In applications exposed to harsh environments, the economic advantages of duplex stainless steel become more pronounced, outweighing upfront investment through extended durability and reduced replacement frequency.

Fabrication and Welding Challenges

Duplex stainless steels present unique fabrication and welding challenges due to their dual-phase microstructure, requiring precise control of heat input to maintain the balance between ferrite and austenite for optimal corrosion resistance and mechanical properties. Austenitic stainless steels, known for their excellent weldability, are less sensitive to thermal cycles but can suffer from issues like hot cracking if welding parameters are not carefully managed. Both materials demand specific filler metals and post-weld heat treatments to reduce residual stresses and prevent sensitization or unwanted phase transformations.

Resistance to Stress Corrosion Cracking

Duplex stainless steels exhibit superior resistance to stress corrosion cracking (SCC) due to their balanced microstructure of austenite and ferrite phases that enhances mechanical strength and corrosion resistance. Austenitic stainless steels, while offering excellent general corrosion resistance, are more susceptible to SCC in chloride-rich environments. The increased resistance of duplex stainless steels makes them preferable for applications in aggressive environments such as marine and chemical processing industries.

Longevity and Durability Factors

Duplex stainless steel offers superior longevity and durability compared to austenitic stainless due to its unique microstructure combining austenite and ferrite phases, which enhances resistance to stress corrosion cracking and pitting. Its higher strength reduces material thickness requirements while maintaining corrosion resistance in aggressive environments, extending service life. Austenitic stainless steel, while corrosion-resistant and ductile, generally exhibits lower yield strength and is more susceptible to chloride-induced stress corrosion, limiting durability in harsh conditions.

Choosing the Right Stainless Steel for Your Application

Duplex stainless steel offers superior strength and corrosion resistance compared to austenitic stainless steel, making it ideal for aggressive environments such as chemical processing and marine applications. Austenitic stainless steel, known for its excellent formability and weldability, is well-suited for food processing, architectural structures, and automotive components. Selecting the right stainless steel depends on factors like stress resistance, exposure conditions, and cost-efficiency to ensure optimal performance and longevity.

Duplex Stainless vs Austenitic Stainless Infographic

materialdif.com

materialdif.com