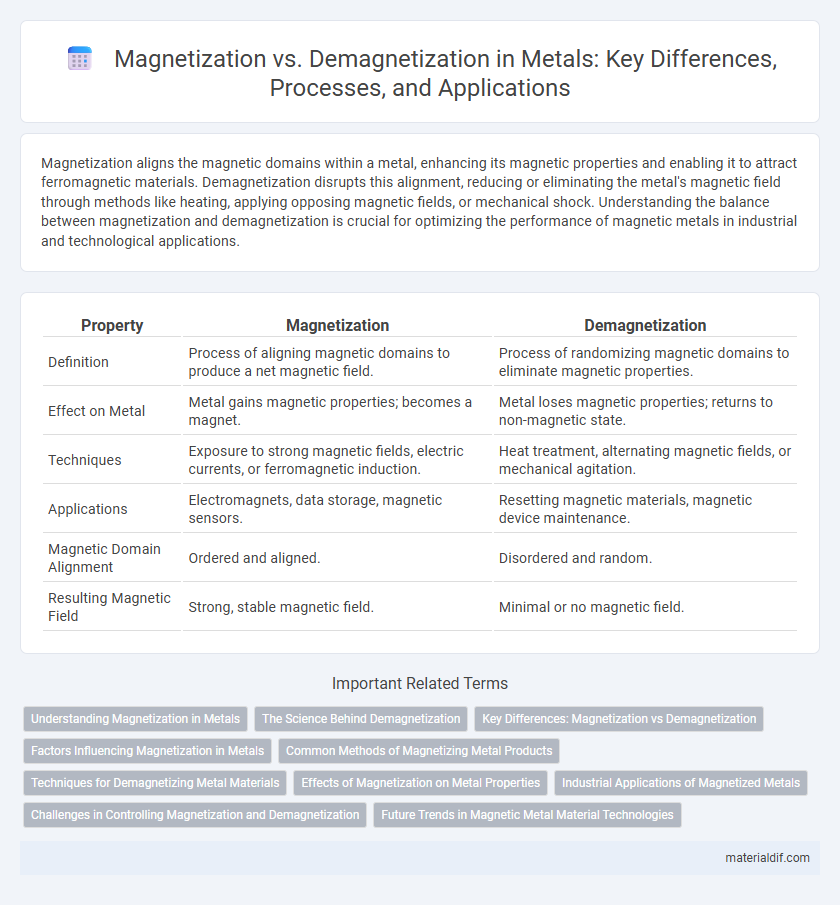

Magnetization aligns the magnetic domains within a metal, enhancing its magnetic properties and enabling it to attract ferromagnetic materials. Demagnetization disrupts this alignment, reducing or eliminating the metal's magnetic field through methods like heating, applying opposing magnetic fields, or mechanical shock. Understanding the balance between magnetization and demagnetization is crucial for optimizing the performance of magnetic metals in industrial and technological applications.

Table of Comparison

| Property | Magnetization | Demagnetization |

|---|---|---|

| Definition | Process of aligning magnetic domains to produce a net magnetic field. | Process of randomizing magnetic domains to eliminate magnetic properties. |

| Effect on Metal | Metal gains magnetic properties; becomes a magnet. | Metal loses magnetic properties; returns to non-magnetic state. |

| Techniques | Exposure to strong magnetic fields, electric currents, or ferromagnetic induction. | Heat treatment, alternating magnetic fields, or mechanical agitation. |

| Applications | Electromagnets, data storage, magnetic sensors. | Resetting magnetic materials, magnetic device maintenance. |

| Magnetic Domain Alignment | Ordered and aligned. | Disordered and random. |

| Resulting Magnetic Field | Strong, stable magnetic field. | Minimal or no magnetic field. |

Understanding Magnetization in Metals

Magnetization in metals occurs when magnetic moments of atoms align under an external magnetic field, leading to a net magnetic moment. This alignment depends on the metal's electron configuration and crystal structure, with ferromagnetic metals like iron, cobalt, and nickel exhibiting strong spontaneous magnetization. Understanding how temperature, impurities, and phase changes affect magnetization aids in controlling magnetic properties for industrial applications such as data storage and electric motors.

The Science Behind Demagnetization

Demagnetization occurs when the aligned magnetic domains within a metal lose their uniform orientation, disrupting the material's overall magnetic field. Thermal agitation, mechanical shock, or exposure to an alternating magnetic field can cause this randomization of domain alignment. Understanding the atomic-level interactions and energy barriers involved in domain realignment is crucial for controlling and optimizing the magnetization process in ferromagnetic metals.

Key Differences: Magnetization vs Demagnetization

Magnetization involves aligning magnetic domains within a metal, enhancing its magnetic field strength and enabling it to attract ferromagnetic materials like iron and cobalt. Demagnetization reverses this process by disrupting the magnetic domain alignment through heat, alternating magnetic fields, or mechanical shock, reducing the metal's magnetic properties. Key differences include the increase of net magnetic moment during magnetization versus the decrease or elimination of magnetic properties during demagnetization.

Factors Influencing Magnetization in Metals

Magnetization in metals is primarily influenced by factors such as the type of metal, crystal structure, temperature, and external magnetic fields. Ferromagnetic metals like iron, cobalt, and nickel exhibit strong magnetization due to the alignment of magnetic domains within their crystalline lattice. Elevated temperatures can disrupt this domain alignment, reducing magnetization, while strong external magnetic fields enhance domain orientation, increasing the metal's magnetic properties.

Common Methods of Magnetizing Metal Products

Common methods of magnetizing metal products include stroking with a permanent magnet, placing the metal within a coil and applying an electric current (electromagnetic induction), and using magnetic fields generated by solenoids or Helmholtz coils. These techniques align the magnetic domains within ferromagnetic materials such as iron, cobalt, and nickel, creating a net magnetic moment. Magnetization efficiency depends on factors like the metal's composition, shape, temperature, and the strength and duration of the applied magnetic field.

Techniques for Demagnetizing Metal Materials

Techniques for demagnetizing metal materials include thermal demagnetization, where heating the metal above its Curie temperature disrupts magnetic domains, effectively erasing magnetization. Another common method is applying an alternating magnetic field with gradually decreasing amplitude, known as AC demagnetization or degaussing, which randomizes the alignment of magnetic domains. Mechanical shock or vibration can also alleviate residual magnetism by physically disturbing domain structures within ferromagnetic metals.

Effects of Magnetization on Metal Properties

Magnetization significantly enhances the magnetic permeability and coercivity of ferromagnetic metals, altering their internal domain structures and increasing their ability to retain magnetic properties. This process improves electrical conductivity and mechanical strength while influencing the metal's susceptibility to corrosion and wear. Changes in magnetization also affect the metal's thermal conductivity and magnetic hysteresis behavior, critical for applications in transformers and electric motors.

Industrial Applications of Magnetized Metals

Magnetized metals enhance industrial applications by improving the efficiency of electric motors, transformers, and magnetic sensors, where strong and stable magnetization ensures optimal performance. Demagnetization plays a critical role in recycling processes and precision manufacturing, enabling reusability and accurate control over magnetic properties. Industries rely on tailored magnetization techniques to optimize energy consumption and extend the lifespan of magnetic components in heavy machinery and electronic devices.

Challenges in Controlling Magnetization and Demagnetization

Controlling magnetization and demagnetization in metals faces challenges such as thermal fluctuations that disrupt stable magnetic states and material impurities that create inconsistent magnetic domains. The complex interplay between magnetic anisotropy and external magnetic fields demands precise calibration to achieve targeted magnetic behavior. Advanced techniques like ultrafast laser pulses and nanoscale patterning are being explored to overcome these hurdles and enable reliable magnetization control.

Future Trends in Magnetic Metal Material Technologies

Emerging advancements in magnetic metal material technologies are focused on enhancing magnetization efficiency through novel alloy compositions and nanostructuring techniques, enabling stronger and more stable magnetic fields at reduced energy costs. Innovations in demagnetization control involve developing materials with tunable coercivity and improved thermal stability, critical for applications in data storage and electric motors. Future trends emphasize sustainable fabrication processes and integration of rare-earth-free magnets to mitigate supply risks and environmental impact.

Magnetization vs Demagnetization Infographic

materialdif.com

materialdif.com