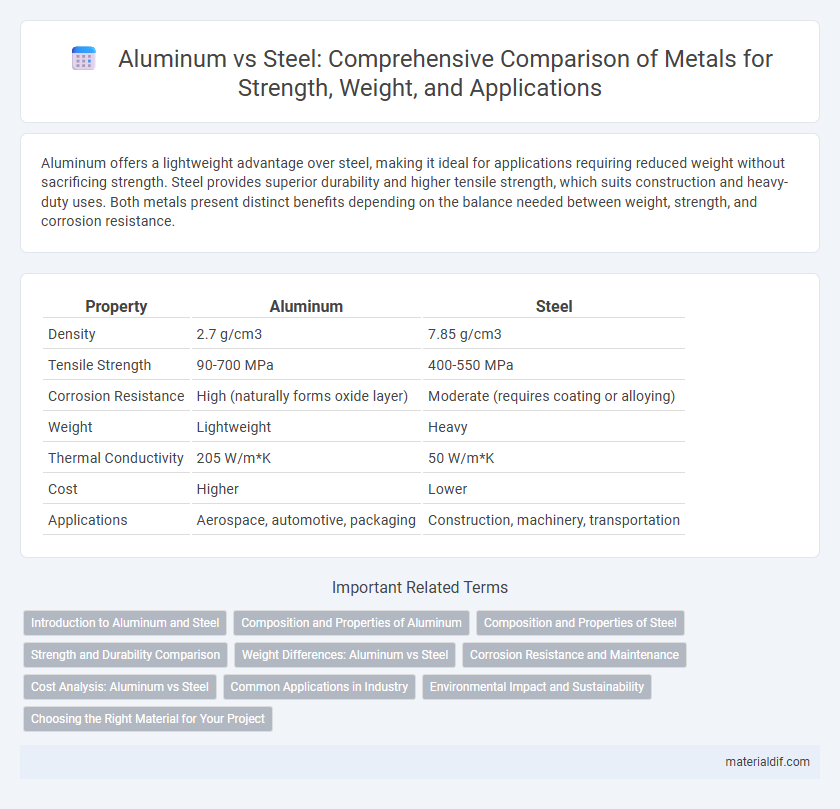

Aluminum offers a lightweight advantage over steel, making it ideal for applications requiring reduced weight without sacrificing strength. Steel provides superior durability and higher tensile strength, which suits construction and heavy-duty uses. Both metals present distinct benefits depending on the balance needed between weight, strength, and corrosion resistance.

Table of Comparison

| Property | Aluminum | Steel |

|---|---|---|

| Density | 2.7 g/cm3 | 7.85 g/cm3 |

| Tensile Strength | 90-700 MPa | 400-550 MPa |

| Corrosion Resistance | High (naturally forms oxide layer) | Moderate (requires coating or alloying) |

| Weight | Lightweight | Heavy |

| Thermal Conductivity | 205 W/m*K | 50 W/m*K |

| Cost | Higher | Lower |

| Applications | Aerospace, automotive, packaging | Construction, machinery, transportation |

Introduction to Aluminum and Steel

Aluminum and steel are two fundamental metals used extensively across industries due to their distinct properties. Aluminum offers lightweight characteristics and excellent corrosion resistance, making it ideal for aerospace, transportation, and packaging applications. Steel, known for its superior strength and durability, dominates construction, automotive, and heavy machinery sectors, with variations like carbon steel and stainless steel tailored for specific performance needs.

Composition and Properties of Aluminum

Aluminum is a lightweight metal primarily composed of aluminum atoms with trace amounts of elements such as copper, magnesium, and silicon, enhancing its strength and corrosion resistance. Its low density, approximately 2.7 g/cm3, makes it significantly lighter than steel, which has a density around 7.85 g/cm3. Aluminum exhibits excellent thermal and electrical conductivity, superior corrosion resistance due to its natural oxide layer, and a high strength-to-weight ratio, making it ideal for aerospace and automotive applications.

Composition and Properties of Steel

Steel is primarily composed of iron with carbon content ranging from 0.02% to 2.1%, which significantly influences its hardness, tensile strength, and ductility. Alloying elements such as manganese, chromium, nickel, and vanadium enhance steel's corrosion resistance, toughness, and heat resistance, distinguishing it from aluminum's lighter but less strong characteristics. The crystalline structure of steel, typically body-centered cubic or face-centered cubic, contributes to its high melting point and superior mechanical properties compared to aluminum's face-centered cubic structure.

Strength and Durability Comparison

Aluminum offers a high strength-to-weight ratio, making it ideal for applications where weight reduction is critical, but it typically has lower tensile strength than steel. Steel exhibits superior durability and can withstand higher stress and impact levels, making it the preferred choice for heavy-duty construction and structural applications. The corrosion resistance of aluminum often surpasses that of steel unless steel is treated or alloyed for enhanced protection.

Weight Differences: Aluminum vs Steel

Aluminum weighs approximately 2.7 grams per cubic centimeter, significantly lighter than steel, which averages around 7.85 grams per cubic centimeter. This weight difference means aluminum is about one-third the density of steel, making it ideal for applications where reducing weight is crucial, such as in aerospace and automotive industries. Despite its lightness, aluminum offers a high strength-to-weight ratio but generally requires thicker sections compared to steel to achieve equivalent strength.

Corrosion Resistance and Maintenance

Aluminum exhibits superior corrosion resistance compared to steel due to its natural oxide layer that protects it from rust and environmental damage. Steel requires regular maintenance such as painting or galvanizing to prevent corrosion, especially in humid or marine environments. Choosing aluminum reduces long-term maintenance costs and enhances durability in corrosive conditions.

Cost Analysis: Aluminum vs Steel

Aluminum generally has a higher initial cost compared to steel, primarily due to its extraction and refining processes. Steel, being more abundant and easier to produce, offers lower material costs but may incur higher expenses in corrosion protection and maintenance over time. When evaluating total cost of ownership, aluminum's lightweight properties can lead to savings in transportation and fuel efficiency, potentially offsetting its higher upfront price in applications like automotive and aerospace industries.

Common Applications in Industry

Aluminum is favored in aerospace, automotive, and packaging industries due to its lightweight and corrosion resistance, making it ideal for aircraft frames, car bodies, and beverage cans. Steel is predominantly used in construction, manufacturing, and heavy machinery for its superior strength and durability, commonly found in bridges, buildings, and industrial equipment. Both metals are essential, with aluminum excelling in applications requiring reduced weight and steel preferred for structural integrity and load-bearing uses.

Environmental Impact and Sustainability

Aluminum production consumes less energy than steel manufacturing, resulting in lower carbon emissions per ton produced, making it a more environmentally friendly option in terms of greenhouse gases. However, aluminum requires significant mining and refining of bauxite, which can have considerable ecological impacts, while steel's recyclability rate exceeds 90%, enhancing its sustainability credentials through circular economy practices. Choosing between aluminum and steel depends on balancing energy efficiency, resource extraction impacts, and recycling potential to achieve sustainable material use.

Choosing the Right Material for Your Project

Aluminum offers lightweight strength and excellent corrosion resistance, making it ideal for projects requiring durability without added weight, such as aerospace and automotive applications. Steel provides superior tensile strength and cost-effectiveness, suitable for heavy-duty structural projects and construction where load-bearing and impact resistance are critical. Evaluating factors like environmental exposure, weight constraints, and budget ensures the optimal choice between aluminum and steel for your specific material needs.

Aluminum vs Steel Infographic

materialdif.com

materialdif.com