Sintered metal offers superior porosity and uniform microstructure, providing excellent wear resistance and enhanced mechanical properties compared to welded metal, which may suffer from heat-affected zones and potential weaknesses at joints. The sintering process fuses metal powders without melting, resulting in consistent density and reduced distortion, while welding joins metal pieces but can introduce residual stresses and potential defects. Choosing sintered metal ensures better dimensional accuracy and fatigue strength in high-performance applications where structural integrity is critical.

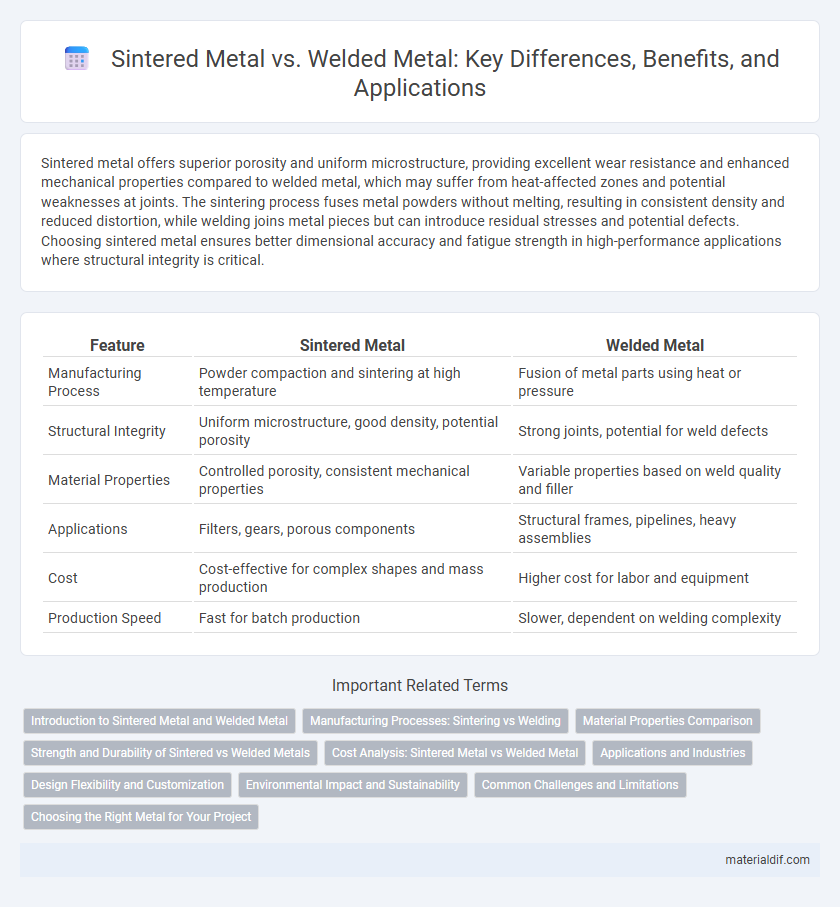

Table of Comparison

| Feature | Sintered Metal | Welded Metal |

|---|---|---|

| Manufacturing Process | Powder compaction and sintering at high temperature | Fusion of metal parts using heat or pressure |

| Structural Integrity | Uniform microstructure, good density, potential porosity | Strong joints, potential for weld defects |

| Material Properties | Controlled porosity, consistent mechanical properties | Variable properties based on weld quality and filler |

| Applications | Filters, gears, porous components | Structural frames, pipelines, heavy assemblies |

| Cost | Cost-effective for complex shapes and mass production | Higher cost for labor and equipment |

| Production Speed | Fast for batch production | Slower, dependent on welding complexity |

Introduction to Sintered Metal and Welded Metal

Sintered metal is produced by compacting powdered metal and heating it below its melting point, resulting in a porous yet strong structure ideal for complex shapes and precise tolerances. Welded metal joins two metal pieces by melting their surfaces and adding filler material, creating a solid and continuous bond commonly used for structural applications. Both methods are fundamental in manufacturing, with sintered metal excelling in precision and material efficiency and welded metal offering robust connections and versatility.

Manufacturing Processes: Sintering vs Welding

Sintered metal manufacturing involves compacting metal powders under heat below their melting point to form a solid piece, optimizing material usage and allowing complex shapes with minimal waste. Welding joins separate metal components by melting and fusing them at high temperatures, providing strong joints but often requiring additional finishing and resulting in potential heat-affected zones. The sintering process yields uniform microstructures for enhanced material properties, whereas welding provides structural reinforcement but may introduce residual stresses due to thermal cycling.

Material Properties Comparison

Sintered metal exhibits superior porosity control and uniform microstructure, enhancing wear resistance and fatigue strength compared to welded metal, which often features localized stress concentrations and potential weld defects. Sintering provides better dimensional accuracy and mechanical consistency due to the diffusion bonding process, whereas welding can introduce residual stresses and heat-affected zones that compromise material integrity. Corrosion resistance is generally higher in sintered metals given the absence of weld seams that can act as initiation sites for corrosion.

Strength and Durability of Sintered vs Welded Metals

Sintered metals exhibit superior uniform strength due to their porous, yet tightly bonded microstructure, which evenly distributes stress and resists fatigue better than welded metals. Welded metals often have localized heat-affected zones that can introduce weaknesses and residual stresses, reducing overall durability and increasing susceptibility to cracking. The consistent grain integrity in sintered components typically results in enhanced long-term performance under dynamic and high-stress conditions compared to welded counterparts.

Cost Analysis: Sintered Metal vs Welded Metal

Sintered metal typically offers lower production costs due to efficient material utilization and reduced machining requirements compared to welded metal, which often involves higher labor and equipment expenses. Welded metal incurs additional costs from skilled labor, energy consumption, and post-weld treatments such as grinding or inspection to ensure structural integrity. Cost analysis between sintered and welded metal must consider factors like volume production, part complexity, and required mechanical properties to determine overall economic efficiency.

Applications and Industries

Sintered metal is widely used in automotive and aerospace industries for producing complex, high-precision parts like gears, filters, and bearings due to its porous structure and cost-effective manufacturing process. Welded metal finds extensive application in construction, shipbuilding, and heavy machinery industries where strong, durable joints are critical for structural integrity and load-bearing components. Both methods serve distinct purposes with sintered metal preferred for lightweight, precise components and welded metal favored for robust, large-scale assemblies.

Design Flexibility and Customization

Sintered metal offers superior design flexibility and customization due to its ability to form complex geometries and intricate internal structures that are difficult or impossible to achieve with welded metal. The powder metallurgy process allows precise control over material composition and porosity, enabling tailored mechanical properties for specific applications. In contrast, welded metal is constrained by joint design limitations and typically requires additional machining, reducing its adaptability for highly customized or intricate parts.

Environmental Impact and Sustainability

Sintered metal manufacturing generates less waste and consumes lower energy compared to welded metal processes, significantly reducing its environmental footprint. The porosity of sintered metals allows for improved recyclability and material efficiency, minimizing resource depletion. Welded metal often requires additional treatments and energy-intensive processes, resulting in higher greenhouse gas emissions and reduced sustainability.

Common Challenges and Limitations

Sintered metal often faces challenges such as porosity, limited mechanical strength, and dimensional variations, which can affect its load-bearing capacity and surface finish. Welded metal encounters limitations including residual stresses, distortion, and potential weakness in the heat-affected zone, compromising structural integrity. Both methods require careful control of process parameters to mitigate defects and ensure consistent performance in industrial applications.

Choosing the Right Metal for Your Project

Sintered metal offers superior porosity control and wear resistance, making it ideal for applications requiring precise filtration or lubrication. Welded metal provides exceptional joint strength and structural integrity, suitable for heavy-duty frameworks or load-bearing components. Selecting between sintered and welded metal depends on project requirements such as mechanical stress, environmental exposure, and desired longevity.

Sintered Metal vs Welded Metal Infographic

materialdif.com

materialdif.com