Alloy steel contains various elements such as chromium, nickel, and molybdenum to enhance strength, toughness, and corrosion resistance, making it suitable for structural and mechanical applications. Tool steel is a specific type of alloy steel designed for high hardness, wear resistance, and the ability to retain a sharp cutting edge, ideal for manufacturing cutting tools and dies. Understanding the distinct properties of alloy steel and tool steel is essential for selecting the right material for engineering tasks requiring durability and precision.

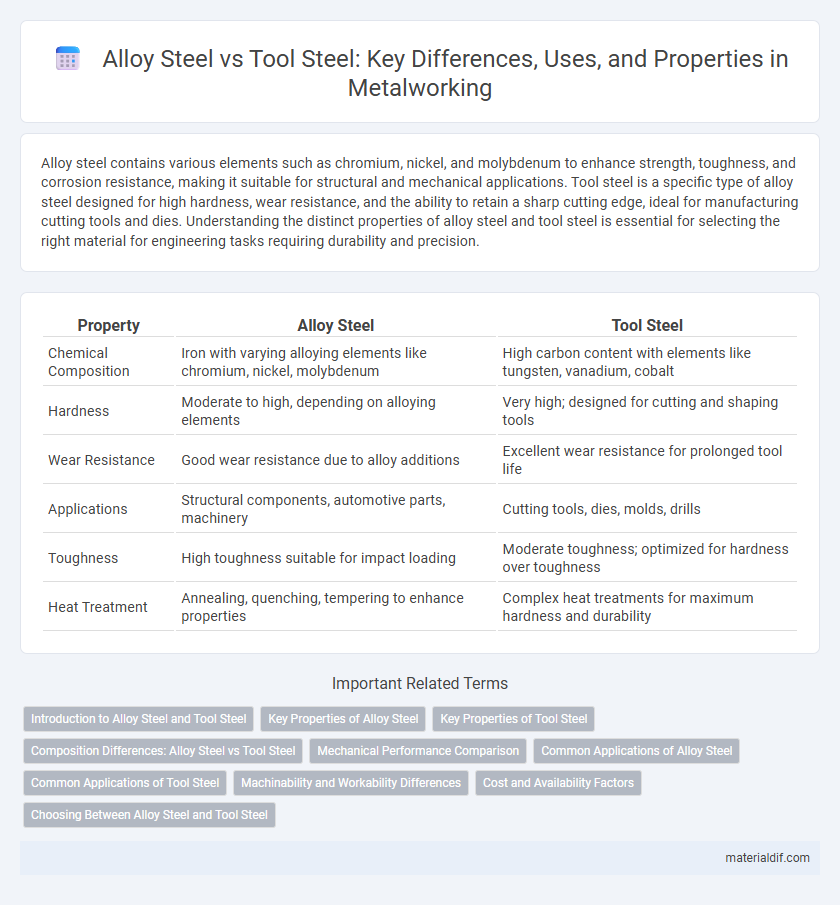

Table of Comparison

| Property | Alloy Steel | Tool Steel |

|---|---|---|

| Chemical Composition | Iron with varying alloying elements like chromium, nickel, molybdenum | High carbon content with elements like tungsten, vanadium, cobalt |

| Hardness | Moderate to high, depending on alloying elements | Very high; designed for cutting and shaping tools |

| Wear Resistance | Good wear resistance due to alloy additions | Excellent wear resistance for prolonged tool life |

| Applications | Structural components, automotive parts, machinery | Cutting tools, dies, molds, drills |

| Toughness | High toughness suitable for impact loading | Moderate toughness; optimized for hardness over toughness |

| Heat Treatment | Annealing, quenching, tempering to enhance properties | Complex heat treatments for maximum hardness and durability |

Introduction to Alloy Steel and Tool Steel

Alloy steel is a versatile material composed of iron combined with elements such as chromium, nickel, and molybdenum to enhance strength, hardness, and corrosion resistance for diverse industrial applications. Tool steel, a specialized subset of alloy steel, contains higher carbon content and specific alloying elements like tungsten and vanadium to optimize hardness and wear resistance for cutting and machining tools. Both materials serve critical roles in manufacturing, with alloy steel favored for structural components and tool steel engineered for high-performance tools.

Key Properties of Alloy Steel

Alloy steel is characterized by the addition of elements such as chromium, nickel, and molybdenum, which enhance its strength, toughness, and corrosion resistance compared to plain carbon steel. It offers high tensile strength and improved hardness, making it suitable for structural components and high-stress applications. Unlike tool steel, alloy steel generally has better weldability and is often used in automotive and aerospace industries due to its versatile mechanical properties.

Key Properties of Tool Steel

Tool steel exhibits exceptional hardness, wear resistance, and the ability to retain a sharp cutting edge at high temperatures, making it ideal for manufacturing cutting tools and dies. Its superior toughness and resistance to deformation under stress contrast with alloy steel, which typically offers enhanced strength and corrosion resistance but lacks the extreme hardness levels necessary for precision tooling. The inclusion of elements such as tungsten, molybdenum, and vanadium in tool steel formulations significantly improves its heat resistance and durability during intensive machining operations.

Composition Differences: Alloy Steel vs Tool Steel

Alloy steel contains a variety of elements such as chromium, nickel, molybdenum, and vanadium, tailored to enhance strength, toughness, and corrosion resistance for general applications. Tool steel, on the other hand, is specifically enriched with high carbon content and tungsten, cobalt, or molybdenum to provide exceptional hardness and wear resistance required for cutting and shaping tools. The distinct compositions define their primary uses, with alloy steel optimized for structural purposes and tool steel engineered for durability under high-stress conditions.

Mechanical Performance Comparison

Alloy steel exhibits enhanced tensile strength and toughness due to its balanced composition of elements like chromium, nickel, and molybdenum, making it ideal for structural applications requiring high durability. Tool steel outperforms alloy steel in hardness and wear resistance, attributed to its high carbon content and specialized alloying elements such as tungsten and vanadium, which provide superior cutting and shaping capabilities. Mechanical performance comparison reveals that alloy steel excels in impact resistance and ductility, while tool steel offers exceptional hardness and thermal stability under high-stress conditions.

Common Applications of Alloy Steel

Alloy steel is widely used in automotive components, structural applications, and heavy machinery due to its enhanced strength, toughness, and corrosion resistance. Its versatility makes it ideal for manufacturing gears, shafts, and pipelines where durability under stress is critical. Unlike tool steel, which is primarily designed for cutting and forming tools, alloy steel supports large-scale industrial and construction uses.

Common Applications of Tool Steel

Tool steel is primarily used in applications requiring high hardness, wear resistance, and the ability to retain a sharp edge, such as cutting tools, dies, molds, and punches. Its superior toughness and heat resistance make it ideal for manufacturing components like blades, drill bits, and extrusion tools in the metalworking and automotive industries. Unlike alloy steel, tool steel is specifically engineered to withstand repeated impact and high temperatures during machining processes.

Machinability and Workability Differences

Alloy steel exhibits better machinability due to its lower carbon content and the presence of alloying elements like chromium and nickel that enhance toughness and reduce tool wear. Tool steel, designed for high hardness and wear resistance, typically has a higher carbon and alloy content, leading to greater difficulty in machining and requiring specialized cutting tools. Workability favors alloy steel as it can be more easily formed and welded, while tool steel's hardness limits deformation and necessitates heat treatment for shaping.

Cost and Availability Factors

Alloy steel generally offers lower costs and higher availability due to its widespread use in construction and automotive industries, making it more accessible for large-scale projects. Tool steel, characterized by its superior hardness and wear resistance, comes at a premium price and limited availability because of specialized alloying elements like tungsten and vanadium. Budget-sensitive projects often favor alloy steel, while applications requiring high durability and precision tools justify the higher expense of tool steel.

Choosing Between Alloy Steel and Tool Steel

Selecting between alloy steel and tool steel depends primarily on the intended application and mechanical properties required. Alloy steel offers enhanced strength, toughness, and corrosion resistance due to its varied alloying elements such as chromium, nickel, and molybdenum, making it ideal for structural components and automotive parts. Tool steel, characterized by high hardness, wear resistance, and heat resistance from elements like tungsten and vanadium, is best suited for cutting tools, molds, and dies requiring sustained performance under extreme conditions.

Alloy Steel vs Tool Steel Infographic

materialdif.com

materialdif.com