Extrusion shapes metal by forcing it through a die, creating continuous profiles with consistent cross-sections ideal for complex, lightweight parts. Machining removes material from a solid block using cutting tools, offering high precision and flexibility for intricate details and tight tolerances. Selecting between extrusion and machining depends on production volume, design complexity, and cost-efficiency requirements.

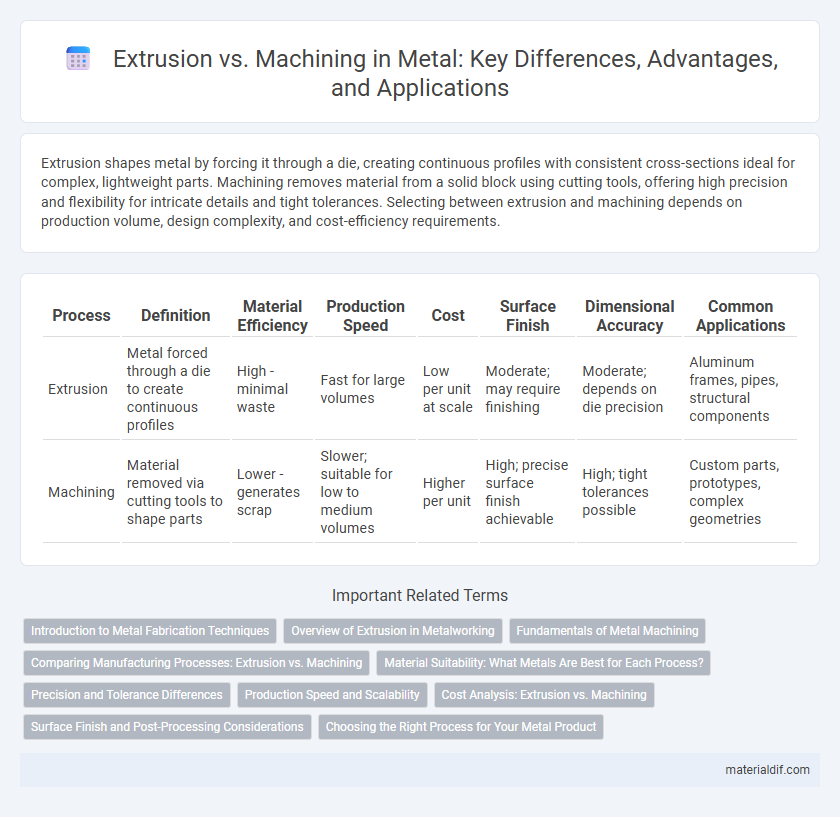

Table of Comparison

| Process | Definition | Material Efficiency | Production Speed | Cost | Surface Finish | Dimensional Accuracy | Common Applications |

|---|---|---|---|---|---|---|---|

| Extrusion | Metal forced through a die to create continuous profiles | High - minimal waste | Fast for large volumes | Low per unit at scale | Moderate; may require finishing | Moderate; depends on die precision | Aluminum frames, pipes, structural components |

| Machining | Material removed via cutting tools to shape parts | Lower - generates scrap | Slower; suitable for low to medium volumes | Higher per unit | High; precise surface finish achievable | High; tight tolerances possible | Custom parts, prototypes, complex geometries |

Introduction to Metal Fabrication Techniques

Extrusion and machining are fundamental metal fabrication techniques used to shape metals with distinct advantages. Extrusion involves forcing metal through a die to create continuous profiles with consistent cross-sections, ideal for producing complex shapes efficiently. Machining removes material from a metal workpiece using cutting tools, allowing for high precision and intricate detailing in metal parts.

Overview of Extrusion in Metalworking

Extrusion in metalworking involves forcing heated metal billets through a shaped die to create long objects with uniform cross-sections, such as rods, pipes, and profiles. This process enhances material properties by refining grain structure and reducing waste compared to machining, which removes material from a solid block. Extrusion suits high-volume production of complex shapes with consistent mechanical strength, outperforming machining in efficiency and material utilization.

Fundamentals of Metal Machining

Metal machining involves removing material from a metal workpiece using cutting tools, emphasizing precision and surface finish, while extrusion shapes metal by forcing it through a die, producing long lengths with consistent cross-sections. Machining offers greater dimensional accuracy and complex geometries compared to extrusion, which is limited to simpler profiles. Fundamental machining processes include turning, milling, drilling, and grinding, each optimizing tool-material interaction to enhance efficiency and reduce waste.

Comparing Manufacturing Processes: Extrusion vs. Machining

Extrusion produces metal components by forcing material through a shaped die, enabling consistent cross-sections and minimizing waste, ideal for complex profiles and high-volume production. Machining removes material from a solid metal block using cutting tools, offering high precision and intricate detailing but generating more scrap metal and longer production times. Choosing between extrusion and machining depends on factors such as design complexity, tolerance requirements, material properties, and cost efficiency for the intended metal manufacturing application.

Material Suitability: What Metals Are Best for Each Process?

Aluminum and copper alloys excel in extrusion due to their high ductility and ability to form complex profiles without cracking. Machining is best suited for harder metals like steel and titanium, which may be too brittle or difficult to shape through extrusion. Choosing the right metal depends on the desired shape complexity and mechanical properties required for the final application.

Precision and Tolerance Differences

Extrusion offers consistent cross-sectional shapes with moderate tolerances typically around +-0.5 mm, making it suitable for parts with less stringent precision requirements. Machining delivers superior precision and tighter tolerances, often within microns, enabling complex geometries and fine detail crucial for high-performance metal components. The choice between extrusion and machining depends on the dimensional accuracy and surface finish demanded by the application.

Production Speed and Scalability

Extrusion offers faster production speeds by enabling continuous shaping of metal profiles, reducing cycle times compared to machining which shapes metal through slower, iterative cutting processes. Scalability in extrusion is higher, as it supports large volume manufacturing with consistent cross-sectional profiles, while machining is better suited for low to medium volume, complex parts with flexible design changes. For high-speed, scalable metal part production, extrusion remains the preferred method over traditional machining processes.

Cost Analysis: Extrusion vs. Machining

Extrusion offers significant cost advantages over machining by reducing material waste and minimizing production time through continuous shaping processes. Machining involves higher labor and tool costs due to its subtractive nature, resulting in increased expenses for complex geometries and lower material utilization rates. For large production runs, extrusion is more economical, while machining remains viable for low-volume, highly detailed metal components.

Surface Finish and Post-Processing Considerations

Extrusion typically produces a smoother surface finish with uniform texture, reducing the need for extensive post-processing compared to machining, which often leaves tool marks and requires polishing or grinding to achieve desired aesthetics. Machining allows for precise dimensional control and complex geometries but may necessitate additional surface treatments like anodizing or coating to enhance corrosion resistance and appearance. Choosing between extrusion and machining depends on balancing surface finish quality requirements with the extent and cost of post-processing operations.

Choosing the Right Process for Your Metal Product

Extrusion offers efficient shaping for complex cross-sections with minimal waste, ideal for producing long metal profiles like aluminum frames and pipes. Machining provides precise dimensions and intricate details, making it suitable for custom parts and tight tolerances in steel or titanium components. Selecting between extrusion and machining depends on factors such as production volume, design complexity, material properties, and cost constraints for your metal product.

Extrusion vs Machining Infographic

materialdif.com

materialdif.com