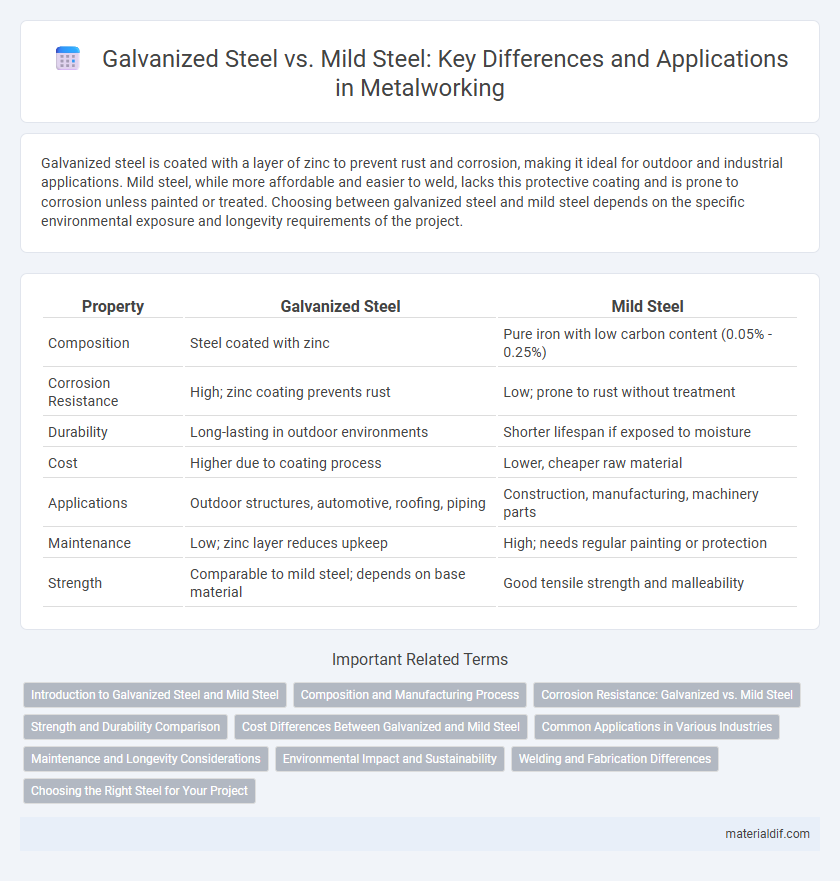

Galvanized steel is coated with a layer of zinc to prevent rust and corrosion, making it ideal for outdoor and industrial applications. Mild steel, while more affordable and easier to weld, lacks this protective coating and is prone to corrosion unless painted or treated. Choosing between galvanized steel and mild steel depends on the specific environmental exposure and longevity requirements of the project.

Table of Comparison

| Property | Galvanized Steel | Mild Steel |

|---|---|---|

| Composition | Steel coated with zinc | Pure iron with low carbon content (0.05% - 0.25%) |

| Corrosion Resistance | High; zinc coating prevents rust | Low; prone to rust without treatment |

| Durability | Long-lasting in outdoor environments | Shorter lifespan if exposed to moisture |

| Cost | Higher due to coating process | Lower, cheaper raw material |

| Applications | Outdoor structures, automotive, roofing, piping | Construction, manufacturing, machinery parts |

| Maintenance | Low; zinc layer reduces upkeep | High; needs regular painting or protection |

| Strength | Comparable to mild steel; depends on base material | Good tensile strength and malleability |

Introduction to Galvanized Steel and Mild Steel

Galvanized steel is carbon steel coated with a layer of zinc to enhance corrosion resistance, making it ideal for outdoor and industrial applications. Mild steel, also known as low carbon steel, contains approximately 0.05% to 0.25% carbon, providing excellent ductility and weldability but lower corrosion resistance compared to galvanized steel. Both materials are widely used in construction, automotive manufacturing, and fabrication, with the choice depending on environmental exposure and strength requirements.

Composition and Manufacturing Process

Galvanized steel consists of a mild steel core coated with a layer of zinc through a hot-dip galvanizing or electro-galvanizing process, enhancing corrosion resistance. Mild steel primarily contains iron with a low carbon content, typically between 0.05% and 0.25%, and undergoes processes such as hot rolling or cold rolling without additional protective coatings. The zinc coating in galvanized steel chemically bonds to the steel surface, providing sacrificial protection, whereas mild steel relies solely on its core material properties for strength and durability.

Corrosion Resistance: Galvanized vs. Mild Steel

Galvanized steel offers superior corrosion resistance due to its protective zinc coating, which acts as a barrier against moisture and environmental pollutants. Mild steel lacks this coating, making it more susceptible to rust and deterioration when exposed to harsh conditions. The zinc layer in galvanized steel extends the lifespan of metal components, especially in outdoor and industrial applications.

Strength and Durability Comparison

Galvanized steel offers superior durability compared to mild steel due to its protective zinc coating that prevents corrosion and rust, extending its lifespan in harsh environments. Mild steel, while possessing strong tensile strength and good weldability, is more susceptible to surface wear and corrosion, reducing its long-term strength in outdoor or moist conditions. The zinc layer on galvanized steel not only enhances corrosion resistance but also maintains structural integrity, making it a preferred choice for construction and industrial applications where strength retention is critical.

Cost Differences Between Galvanized and Mild Steel

Galvanized steel typically costs 15-30% more than mild steel due to the additional zinc coating process that enhances corrosion resistance. While mild steel offers a lower upfront price, galvanized steel provides long-term savings by reducing maintenance and replacement costs in corrosive environments. Cost efficiency depends on project requirements, with galvanized steel favored in outdoor or humid conditions despite its higher initial expense.

Common Applications in Various Industries

Galvanized steel is widely used in construction for roofing, structural frameworks, and outdoor equipment due to its corrosion resistance, while mild steel serves critical roles in automotive manufacturing, machinery parts, and pipelines given its malleability and strength. In the agriculture sector, galvanized steel is preferred for fencing and silos, whereas mild steel is commonly utilized for tools and heavy machinery components. Both materials find applications in fabrication and industrial production, with the choice depending on environmental exposure and mechanical requirements.

Maintenance and Longevity Considerations

Galvanized steel offers superior corrosion resistance due to its protective zinc coating, significantly reducing maintenance requirements compared to mild steel. Mild steel, prone to rust and corrosion when exposed to moisture, demands regular painting or treatment to enhance its lifespan. Over time, galvanized steel's durability can extend decades with minimal upkeep, while mild steel often requires frequent maintenance to prevent structural degradation.

Environmental Impact and Sustainability

Galvanized steel offers enhanced corrosion resistance due to its zinc coating, reducing the frequency of replacement and thereby lowering resource consumption and waste over its lifecycle compared to mild steel. Mild steel, while easier to recycle due to its lack of coating, is more prone to rust and structural degradation, potentially increasing environmental impact through more frequent manufacturing and disposal cycles. The sustainability of galvanized steel is improved by its longevity and protective properties, but the environmental costs of zinc mining and galvanization processes must be considered in a full life-cycle assessment.

Welding and Fabrication Differences

Galvanized steel contains a zinc coating that requires specialized welding techniques such as using lower heat input and proper ventilation to prevent toxic fumes and coating damage, unlike mild steel which welds easily with standard procedures. Fabrication of galvanized steel often involves additional surface treatments and welding precautions to maintain corrosion resistance, whereas mild steel fabrication is more straightforward but prone to rust without protective coatings. The zinc layer on galvanized steel can cause weld defects if not managed properly, impacting joint strength compared to mild steel welds.

Choosing the Right Steel for Your Project

Galvanized steel offers superior corrosion resistance through a zinc coating, making it ideal for outdoor and harsh environments, whereas mild steel provides greater ductility and weldability, suitable for indoor structural applications. Consider project requirements like exposure to moisture, load-bearing needs, and budget constraints when selecting between galvanized and mild steel. Opting for galvanized steel ensures longevity in corrosive settings, while mild steel is preferred for ease of fabrication and cost-effectiveness in controlled conditions.

Galvanized Steel vs Mild Steel Infographic

materialdif.com

materialdif.com