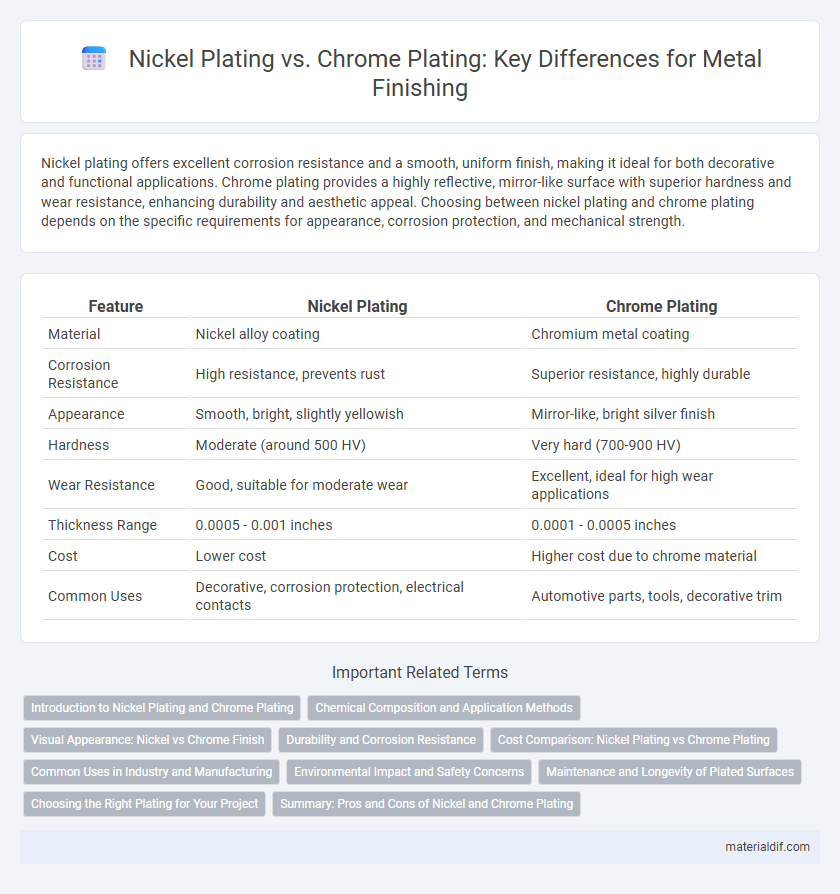

Nickel plating offers excellent corrosion resistance and a smooth, uniform finish, making it ideal for both decorative and functional applications. Chrome plating provides a highly reflective, mirror-like surface with superior hardness and wear resistance, enhancing durability and aesthetic appeal. Choosing between nickel plating and chrome plating depends on the specific requirements for appearance, corrosion protection, and mechanical strength.

Table of Comparison

| Feature | Nickel Plating | Chrome Plating |

|---|---|---|

| Material | Nickel alloy coating | Chromium metal coating |

| Corrosion Resistance | High resistance, prevents rust | Superior resistance, highly durable |

| Appearance | Smooth, bright, slightly yellowish | Mirror-like, bright silver finish |

| Hardness | Moderate (around 500 HV) | Very hard (700-900 HV) |

| Wear Resistance | Good, suitable for moderate wear | Excellent, ideal for high wear applications |

| Thickness Range | 0.0005 - 0.001 inches | 0.0001 - 0.0005 inches |

| Cost | Lower cost | Higher cost due to chrome material |

| Common Uses | Decorative, corrosion protection, electrical contacts | Automotive parts, tools, decorative trim |

Introduction to Nickel Plating and Chrome Plating

Nickel plating involves coating a metal surface with a thin layer of nickel to enhance corrosion resistance, wear resistance, and aesthetic appeal, commonly used in automotive, electronics, and household items. Chrome plating deposits a layer of chromium, offering superior hardness, mirror-like finish, and excellent anticorrosive properties, frequently applied to car parts, plumbing fixtures, and tools. Both methods improve durability and appearance but differ in cost, environmental impact, and specific protective qualities.

Chemical Composition and Application Methods

Nickel plating involves the electrochemical deposition of a nickel alloy, typically containing nickel alongside small amounts of phosphorus or sulfur, providing excellent corrosion resistance and a smooth finish. Chrome plating deposits a thin layer of chromium through electroplating, known for its high hardness, reflective shine, and superior wear resistance. Nickel plating is commonly used for its excellent adhesion and corrosion protection on automotive and electronic parts, whereas chrome plating is preferred for decorative applications and industrial tools requiring durability and aesthetic appeal.

Visual Appearance: Nickel vs Chrome Finish

Nickel plating offers a warm, slightly yellowish tone with a smooth, satin-like finish that enhances the metal's depth and provides a classic, vintage look. Chrome plating delivers a highly reflective, mirror-like surface with a bright, cool silver luster that stands out for its modern and sleek appearance. The visual contrast between nickel's subtle elegance and chrome's striking brilliance makes each plating suited for different aesthetic preferences in metal finishing.

Durability and Corrosion Resistance

Nickel plating offers superior corrosion resistance by forming a dense, protective barrier against oxidation and harsh environmental conditions, making it ideal for industrial applications requiring long-term durability. Chrome plating provides a hard, glossy finish that enhances abrasion resistance but is more prone to cracking and corrosion under extreme stress or moisture exposure. Combining nickel plating underneath chrome plating often yields optimal durability and corrosion resistance for automotive and hardware components.

Cost Comparison: Nickel Plating vs Chrome Plating

Nickel plating generally costs less than chrome plating due to lower material and processing expenses, making it a budget-friendly option for corrosion resistance and decorative finishes. Chrome plating involves higher costs because of its complex deposition process and the premium appearance it provides, which adds value in automotive and appliance industries. Businesses often choose nickel plating for economical durability while reserving chrome plating for aesthetics and enhanced surface hardness despite the higher price.

Common Uses in Industry and Manufacturing

Nickel plating is widely used in the electronics industry for corrosion resistance and improved solderability on components, while chrome plating is preferred in automotive and decorative applications for its high hardness and reflective finish. In manufacturing, nickel plating is common for aerospace parts and machine tools due to its wear resistance, whereas chrome plating is favored for heavy-duty industrial equipment and plumbing fixtures for enhanced durability and aesthetic appeal. Both processes are essential for extending the lifespan and performance of metal products across various industrial sectors.

Environmental Impact and Safety Concerns

Nickel plating involves the use of toxic chemicals like nickel salts and cyanides, posing significant environmental risks due to hazardous waste and potential water contamination. Chrome plating uses hexavalent chromium, a highly carcinogenic substance that presents greater health hazards for workers and more stringent disposal regulations to prevent soil and water pollution. Both methods require strict safety protocols, but environmentally safer alternatives like trivalent chromium plating and nickel-free coatings are being developed to reduce ecological footprints and occupational exposure.

Maintenance and Longevity of Plated Surfaces

Nickel plating offers superior corrosion resistance and smoother finishes, requiring less frequent maintenance compared to chrome plating, which is prone to chipping and wear over time. The durability of nickel-plated surfaces extends the lifespan of metal objects, especially in harsh environments. Chrome plating provides a highly reflective aesthetic but demands more regular upkeep to prevent degradation and maintain its shine.

Choosing the Right Plating for Your Project

Nickel plating offers superior corrosion resistance and a smooth, uniform finish ideal for intricate components, while chrome plating provides a highly reflective, hard surface with excellent wear resistance. Selecting the right plating depends on the application's requirements for durability, aesthetics, and environmental exposure. Projects demanding robust protection against oxidation often favor nickel plating, whereas decorative pieces benefit from the bright, mirror-like shine of chrome plating.

Summary: Pros and Cons of Nickel and Chrome Plating

Nickel plating offers excellent corrosion resistance, a smooth finish, and good wear protection but can be prone to discoloration over time and requires precise control during application. Chrome plating provides superior hardness, a highly reflective surface, and exceptional resistance to scratches but tends to be more brittle and less effective at preventing corrosion compared to nickel. Choosing between nickel and chrome plating depends on the specific requirements for durability, appearance, and environmental exposure of the metal surface.

Nickel Plating vs Chrome Plating Infographic

materialdif.com

materialdif.com