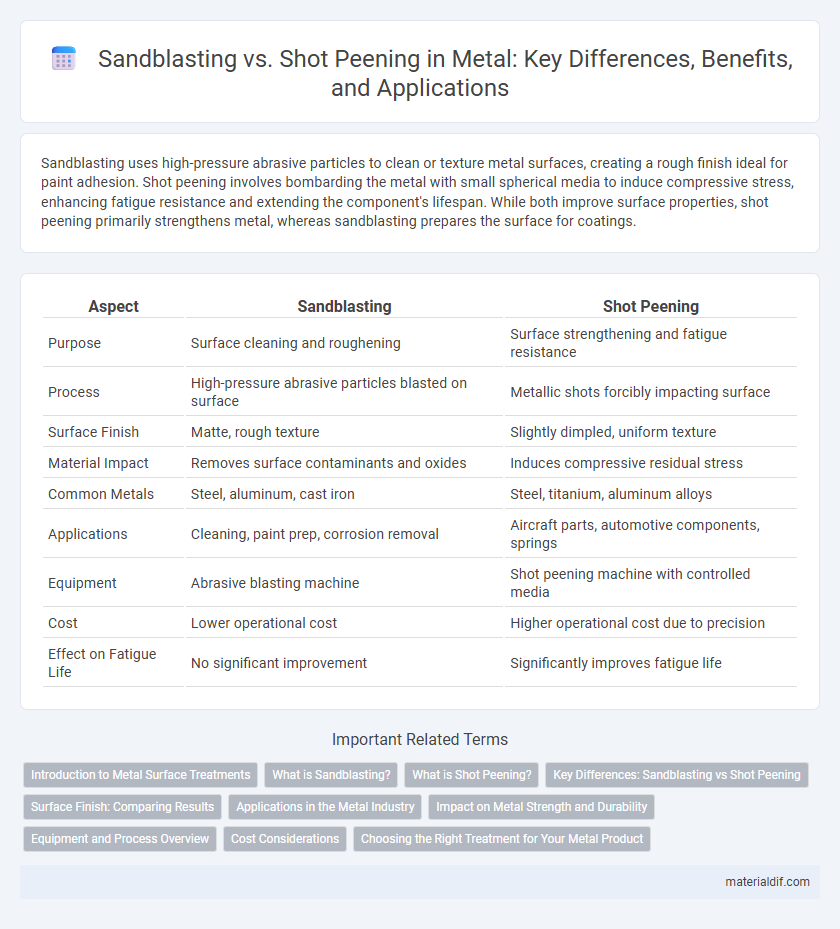

Sandblasting uses high-pressure abrasive particles to clean or texture metal surfaces, creating a rough finish ideal for paint adhesion. Shot peening involves bombarding the metal with small spherical media to induce compressive stress, enhancing fatigue resistance and extending the component's lifespan. While both improve surface properties, shot peening primarily strengthens metal, whereas sandblasting prepares the surface for coatings.

Table of Comparison

| Aspect | Sandblasting | Shot Peening |

|---|---|---|

| Purpose | Surface cleaning and roughening | Surface strengthening and fatigue resistance |

| Process | High-pressure abrasive particles blasted on surface | Metallic shots forcibly impacting surface |

| Surface Finish | Matte, rough texture | Slightly dimpled, uniform texture |

| Material Impact | Removes surface contaminants and oxides | Induces compressive residual stress |

| Common Metals | Steel, aluminum, cast iron | Steel, titanium, aluminum alloys |

| Applications | Cleaning, paint prep, corrosion removal | Aircraft parts, automotive components, springs |

| Equipment | Abrasive blasting machine | Shot peening machine with controlled media |

| Cost | Lower operational cost | Higher operational cost due to precision |

| Effect on Fatigue Life | No significant improvement | Significantly improves fatigue life |

Introduction to Metal Surface Treatments

Sandblasting and shot peening are essential metal surface treatments used to enhance durability and prepare surfaces for further processing. Sandblasting utilizes high-pressure abrasive particles to clean and texture metal surfaces, improving paint adhesion and removing contaminants. Shot peening employs small spherical media to create compressive stresses on metal, increasing fatigue strength and resistance to stress corrosion cracking.

What is Sandblasting?

Sandblasting is a surface treatment process that propels fine abrasive particles at high velocity to clean, smooth, or etch metal surfaces. It effectively removes rust, paint, and contaminants, preparing metals like steel and aluminum for further finishing or coating. This technique enhances surface roughness, improving adhesion for paints and coatings in industrial applications.

What is Shot Peening?

Shot peening is a metal surface treatment process that involves bombarding a metal part with small spherical media called shots to improve its mechanical properties. This technique induces compressive residual stresses on the surface, enhancing fatigue strength, resistance to stress corrosion cracking, and overall durability. Unlike sandblasting, which primarily cleans or roughens surfaces, shot peening is specifically designed to extend the lifespan and performance of metal components in demanding applications.

Key Differences: Sandblasting vs Shot Peening

Sandblasting uses high-pressure air to propel abrasive particles for surface cleaning or texture modification, whereas shot peening employs spherical media to plastically deform and strengthen metal surfaces, inducing beneficial compressive stresses. Sandblasting primarily removes rust, scale, and contaminants without altering the metal's mechanical properties, while shot peening enhances fatigue resistance and durability through surface hardening. The selection between sandblasting and shot peening depends on whether surface preparation or structural improvement is the priority in metal treatment.

Surface Finish: Comparing Results

Sandblasting produces a rougher surface finish by propelling abrasive particles at high velocity to remove contaminants and scale, ideal for preparing metal surfaces for coating. Shot peening creates a smoother, more uniform finish by bombarding the surface with small spherical media, inducing compressive stress that enhances fatigue resistance. The choice depends on the desired surface texture and mechanical properties, with sandblasting emphasizing cleaning and texture, while shot peening prioritizes durability and stress relief.

Applications in the Metal Industry

Sandblasting is widely used in the metal industry for surface preparation, corrosion removal, and cleaning, making it ideal for applications where a smooth finish or paint adhesion is required. Shot peening enhances metal fatigue strength by inducing compressive stresses, which is critical in aerospace, automotive, and heavy machinery components to improve durability and resistance to cracking. Both processes serve distinct purposes, with sandblasting optimizing surface cleanliness and shot peening increasing metal lifespan under cyclic loading conditions.

Impact on Metal Strength and Durability

Sandblasting cleans metal surfaces by propelling abrasive materials at high velocity, enhancing surface texture but having minimal impact on metal strength and durability. Shot peening induces beneficial compressive stress on the metal surface by bombarding it with small spherical media, significantly improving fatigue resistance and longevity. This process increases the durability of components like automotive parts and aerospace alloys by preventing crack initiation and propagation.

Equipment and Process Overview

Sandblasting equipment typically involves a high-pressure air compressor, a blast pot, and abrasive media such as silica sand or aluminum oxide, which is propelled at metal surfaces to remove rust, paint, or scale. Shot peening uses specialized machinery with hardened steel or ceramic shot propelled mechanically or pneumatically to create compressive stresses that improve metal fatigue resistance. Both processes require protective enclosures and precise control mechanisms to ensure consistent surface treatment and operator safety.

Cost Considerations

Sandblasting typically incurs lower initial costs due to simpler equipment and less specialized training compared to shot peening. Shot peening involves higher expenses from precision machinery and ongoing maintenance but provides enhanced surface stress improvement, potentially reducing long-term costs by extending metal fatigue life. Choosing between sandblasting and shot peening depends on balancing upfront investment with desired durability and performance outcomes in metal treatment.

Choosing the Right Treatment for Your Metal Product

When selecting the appropriate surface treatment for metal products, sandblasting is ideal for cleaning and preparing surfaces by removing rust, paint, and contaminants to ensure better adhesion of coatings. Shot peening enhances fatigue strength and resistance to stress corrosion by inducing beneficial compressive stresses on the metal surface, making it suitable for high-performance components like aerospace parts and automotive gears. Evaluating the specific requirements of surface finish, mechanical properties, and intended application is crucial for choosing between sandblasting and shot peening treatments.

Sandblasting vs Shot Peening Infographic

materialdif.com

materialdif.com