Hardening involves rapidly cooling heated metal, usually through quenching, to increase its hardness and strength by forming a martensitic structure. Normalizing heats the metal to a specific temperature and then air cools it to refine the grain structure, improving ductility and toughness while relieving internal stresses. Selecting between hardening and normalizing depends on the desired balance between hardness, strength, and machinability for the metal component.

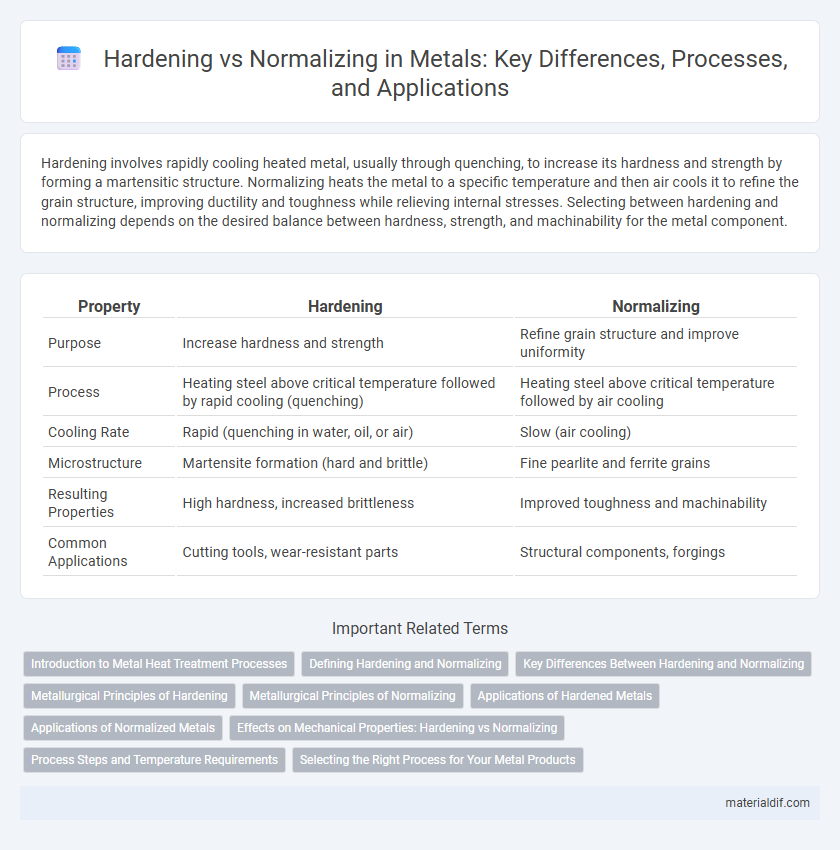

Table of Comparison

| Property | Hardening | Normalizing |

|---|---|---|

| Purpose | Increase hardness and strength | Refine grain structure and improve uniformity |

| Process | Heating steel above critical temperature followed by rapid cooling (quenching) | Heating steel above critical temperature followed by air cooling |

| Cooling Rate | Rapid (quenching in water, oil, or air) | Slow (air cooling) |

| Microstructure | Martensite formation (hard and brittle) | Fine pearlite and ferrite grains |

| Resulting Properties | High hardness, increased brittleness | Improved toughness and machinability |

| Common Applications | Cutting tools, wear-resistant parts | Structural components, forgings |

Introduction to Metal Heat Treatment Processes

Metal heat treatment processes such as hardening and normalizing alter the microstructure to enhance mechanical properties. Hardening involves heating steel above its critical temperature followed by rapid cooling, typically in water or oil, to increase hardness and strength by forming martensite. Normalizing heats the metal to a temperature above the upper critical range and allows it to cool in air, refining grain structure and improving uniformity and toughness.

Defining Hardening and Normalizing

Hardening is a heat treatment process that increases metal hardness and strength by heating the metal to a high temperature and then rapidly cooling it, usually through quenching in water or oil. Normalizing involves heating the metal to a specific temperature above its critical point and allowing it to cool slowly in air to refine the grain structure and improve toughness. Both processes modify the microstructure to enhance mechanical properties but differ in cooling rates and resultant material characteristics.

Key Differences Between Hardening and Normalizing

Hardening increases metal hardness and strength by rapidly cooling from a high temperature, causing a martensitic microstructure. Normalizing refines grain size and improves uniformity by air cooling from austenitizing temperature, enhancing toughness and machinability. The key difference lies in cooling rates--quenching for hardening versus slower air cooling for normalizing--resulting in distinct mechanical properties and microstructures.

Metallurgical Principles of Hardening

Hardening involves heating steel to a temperature above its critical point, followed by rapid cooling or quenching, which transforms the microstructure into martensite, a hard and brittle phase. Normalizing heats the steel above the critical temperature but cools it in air, refining the grain structure and improving toughness without achieving the maximum hardness of hardening. The metallurgical principle of hardening relies on controlling the austenite-to-martensite transformation to increase hardness and strength by trapping carbon atoms within a distorted body-centered tetragonal lattice.

Metallurgical Principles of Normalizing

Normalizing refines the grain structure of steel by heating it above the critical temperature and then air cooling, promoting uniform mechanical properties and enhanced toughness. Unlike hardening, which involves rapid quenching to form martensite, normalizing produces a more uniform pearlitic or bainitic microstructure that reduces internal stresses. This metallurgical process improves machinability and dimensional stability by homogenizing the steel's crystalline phases.

Applications of Hardened Metals

Hardened metals are essential in applications requiring enhanced wear resistance, such as cutting tools, gears, and bearing components, where durability under high stress is critical. These metals exhibit improved hardness and strength due to processes like quenching and tempering, making them suitable for automotive parts, industrial machinery, and aerospace components. In contrast, normalizing refines grain structure for balanced toughness and strength but does not achieve the extreme hardness necessary for heavy-duty applications.

Applications of Normalized Metals

Normalized metals exhibit enhanced toughness and uniform grain structure, making them ideal for critical applications such as automotive components, pressure vessels, and structural steel frameworks. Their improved machinability and resistance to wear extend the lifespan of parts used in heavy machinery and construction equipment. Industries prioritize normalized metals for applications requiring consistent mechanical properties and resistance to fatigue under variable stress conditions.

Effects on Mechanical Properties: Hardening vs Normalizing

Hardening significantly increases the tensile strength and hardness of metal by transforming the microstructure into martensite, enhancing wear resistance but reducing ductility. Normalizing refines grain size through controlled cooling, improving toughness and uniformity without excessively increasing brittleness. These processes balance mechanical properties differently, with hardening favoring strength and normalizing optimizing a combination of strength and ductility.

Process Steps and Temperature Requirements

Hardening involves heating the metal typically between 800degC to 900degC followed by rapid quenching in water or oil to achieve increased hardness and strength. Normalizing requires heating steel to a temperature range of 850degC to 950degC, then air cooling to refine the grain structure and improve toughness and machinability. The key difference lies in cooling methods: quenching in hardening causes a martensitic microstructure, while air cooling in normalizing produces a more uniform pearlitic-ferritic structure.

Selecting the Right Process for Your Metal Products

Hardening increases metal strength and wear resistance by forming martensite through rapid cooling, ideal for tools requiring high durability. Normalizing refines grain structure and relieves internal stresses by heating metal above its critical temperature and air cooling, improving toughness and machinability. Selecting the right process depends on the desired balance between hardness, toughness, and dimensional stability for your metal products.

Hardening vs Normalizing Infographic

materialdif.com

materialdif.com