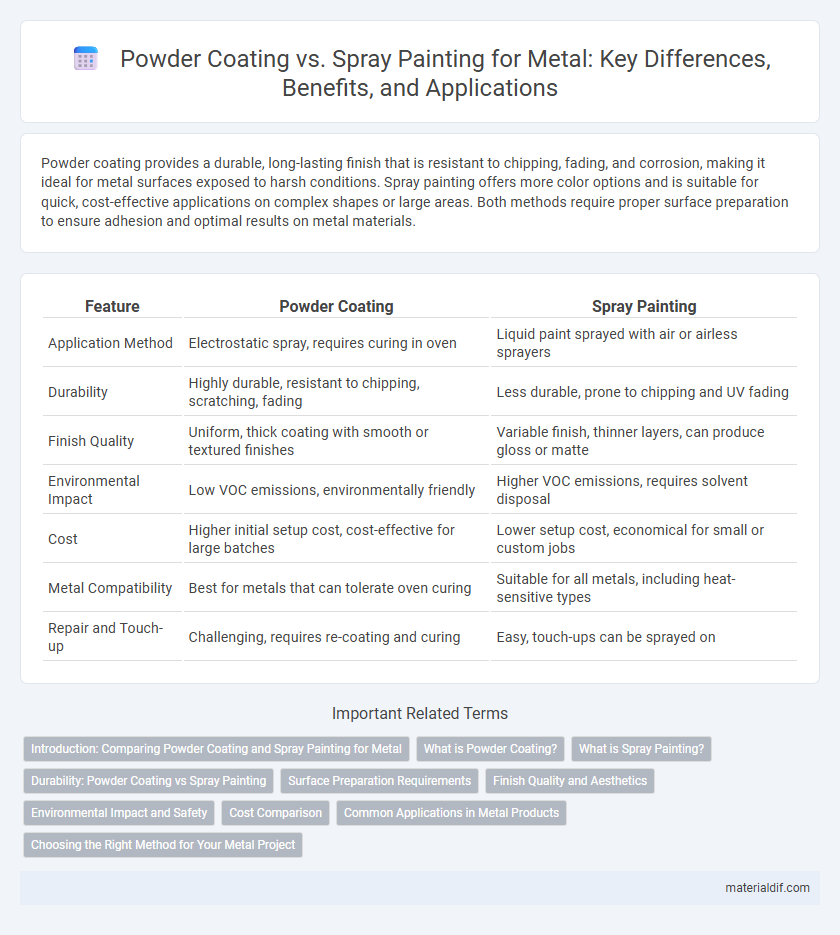

Powder coating provides a durable, long-lasting finish that is resistant to chipping, fading, and corrosion, making it ideal for metal surfaces exposed to harsh conditions. Spray painting offers more color options and is suitable for quick, cost-effective applications on complex shapes or large areas. Both methods require proper surface preparation to ensure adhesion and optimal results on metal materials.

Table of Comparison

| Feature | Powder Coating | Spray Painting |

|---|---|---|

| Application Method | Electrostatic spray, requires curing in oven | Liquid paint sprayed with air or airless sprayers |

| Durability | Highly durable, resistant to chipping, scratching, fading | Less durable, prone to chipping and UV fading |

| Finish Quality | Uniform, thick coating with smooth or textured finishes | Variable finish, thinner layers, can produce gloss or matte |

| Environmental Impact | Low VOC emissions, environmentally friendly | Higher VOC emissions, requires solvent disposal |

| Cost | Higher initial setup cost, cost-effective for large batches | Lower setup cost, economical for small or custom jobs |

| Metal Compatibility | Best for metals that can tolerate oven curing | Suitable for all metals, including heat-sensitive types |

| Repair and Touch-up | Challenging, requires re-coating and curing | Easy, touch-ups can be sprayed on |

Introduction: Comparing Powder Coating and Spray Painting for Metal

Powder coating offers a durable, corrosion-resistant finish ideal for metal surfaces exposed to harsh environments, using electrostatically applied dry powder cured under heat. Spray painting provides versatility with a wide range of colors and finishes, but typically requires multiple coats and offers less durability against chipping and fading. Choosing between powder coating and spray painting depends on factors like environmental exposure, desired finish quality, and project budget.

What is Powder Coating?

Powder coating is a dry finishing process that applies a free-flowing, electrostatically charged powder to metal surfaces, which is then cured under heat to form a hard, durable, and uniform coating. This technique offers superior resistance to corrosion, chipping, and fading compared to traditional liquid spray painting methods. The result is a high-quality, long-lasting finish ideal for automotive parts, appliances, and industrial equipment.

What is Spray Painting?

Spray painting is a technique that applies liquid paint to metal surfaces using a spray gun, providing a smooth and even finish. This method allows for rapid coverage and the ability to reach intricate areas, making it suitable for complex metal parts. Spray painting typically involves solvent-based or water-based paints, ensuring durability and resistance to corrosion on metal substrates.

Durability: Powder Coating vs Spray Painting

Powder coating offers superior durability compared to spray painting due to its thicker, more uniform finish that resists chipping, scratching, and fading over time. Metal surfaces treated with powder coating exhibit enhanced resistance to corrosion and environmental wear, making it ideal for outdoor and industrial applications. Spray painting, while quicker and more versatile in application, typically provides a thinner layer that is more susceptible to damage and requires more frequent maintenance.

Surface Preparation Requirements

Surface preparation for powder coating requires thorough cleaning, degreasing, and abrasive blasting to create a rough profile that ensures strong adhesion and durability. Spray painting demands meticulous cleaning and sometimes light sanding, but generally needs less aggressive surface treatment compared to powder coating. Both methods emphasize contaminant-free surfaces, but powder coating's curing process necessitates superior preparation to prevent coating failures.

Finish Quality and Aesthetics

Powder coating provides a thicker, more uniform finish that is highly resistant to chipping, fading, and scratching, resulting in a durable and aesthetically pleasing surface ideal for metal applications. Spray painting can achieve a smooth and glossy appearance but often requires multiple layers and regular maintenance to prevent wear and discoloration. The superior adhesion and consistent texture of powder coating make it the preferred choice for long-lasting, high-quality metal finishes.

Environmental Impact and Safety

Powder coating produces significantly fewer volatile organic compounds (VOCs) and hazardous air pollutants, making it a more environmentally friendly option compared to spray painting, which releases solvents and fumes harmful to both air quality and worker health. The overspray in powder coating can be collected and reused, reducing waste, whereas spray painting often results in excessive paint loss and chemical runoff. For safety, powder coating poses lower risks of fire and toxic exposure, enhancing workplace safety standards compared to the flammable and toxic solvents used in spray painting.

Cost Comparison

Powder coating offers a cost-effective solution for metal finishing due to lower material waste and reduced labor expenses compared to spray painting. Spray painting incurs higher ongoing costs because of frequent reapplications, solvent use, and environmental compliance fees. Overall, powder coating's durability and efficiency result in lower total expenditure for large-scale metal projects.

Common Applications in Metal Products

Powder coating is widely used for automotive parts, appliances, and outdoor metal furniture due to its durable, corrosion-resistant finish that withstands harsh environments. Spray painting is common in custom metalwork, art installations, and industrial equipment where detailed, quick application and color flexibility are required. Both methods ensure protection and aesthetics, but powder coating is preferred for heavy-duty metal products, while spray painting suits more intricate or small-scale applications.

Choosing the Right Method for Your Metal Project

Powder coating offers superior durability and corrosion resistance for metal projects, making it ideal for outdoor applications and high-wear surfaces. Spray painting provides greater color variety and flexibility for quick touch-ups or small-scale jobs but requires more frequent maintenance. Selecting the right method depends on factors such as environmental exposure, budget, and desired finish longevity.

Powder Coating vs Spray Painting Infographic

materialdif.com

materialdif.com