Powder-coated metal offers a durable, colorful finish that resists chipping, scratching, and fading, making it ideal for vibrant and long-lasting metal pet accessories. Anodized metal, on the other hand, provides enhanced corrosion resistance and maintains the metal's natural texture with a sleek, matte finish, perfect for a minimalist aesthetic. Choosing between powder-coated and anodized metal depends on whether durability and color variety or a subtle, corrosion-resistant surface are priorities for your metal pet products.

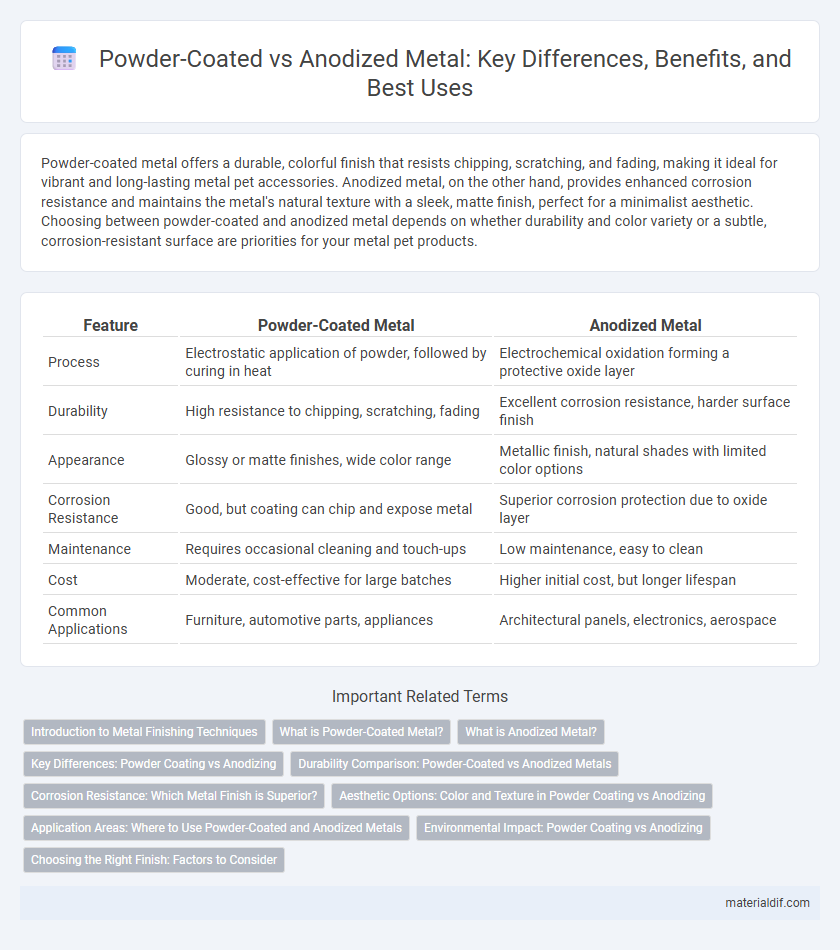

Table of Comparison

| Feature | Powder-Coated Metal | Anodized Metal |

|---|---|---|

| Process | Electrostatic application of powder, followed by curing in heat | Electrochemical oxidation forming a protective oxide layer |

| Durability | High resistance to chipping, scratching, fading | Excellent corrosion resistance, harder surface finish |

| Appearance | Glossy or matte finishes, wide color range | Metallic finish, natural shades with limited color options |

| Corrosion Resistance | Good, but coating can chip and expose metal | Superior corrosion protection due to oxide layer |

| Maintenance | Requires occasional cleaning and touch-ups | Low maintenance, easy to clean |

| Cost | Moderate, cost-effective for large batches | Higher initial cost, but longer lifespan |

| Common Applications | Furniture, automotive parts, appliances | Architectural panels, electronics, aerospace |

Introduction to Metal Finishing Techniques

Powder-coated metal involves applying a dry powder that is cured under heat to form a durable, protective layer resistant to corrosion and wear. Anodized metal undergoes an electrochemical process that thickens the natural oxide layer, enhancing corrosion resistance and surface hardness while allowing for various color finishes. Both techniques improve metal durability and aesthetics, but powder coating provides a thicker, more impact-resistant coating, whereas anodizing retains the metal's original texture with a thinner, more integrated finish.

What is Powder-Coated Metal?

Powder-coated metal is a metal surface treated with a dry powder polymer that is electrostatically applied and cured under heat to form a durable, protective finish. This coating provides excellent resistance to corrosion, chipping, fading, and wear, making it ideal for outdoor and heavy-use applications. The powder coating process creates a uniform, high-quality finish that enhances both the aesthetic appeal and longevity of metal products.

What is Anodized Metal?

Anodized metal is aluminum that has undergone an electrochemical process to form a durable, corrosion-resistant oxide layer on its surface, enhancing its hardness and aesthetic appeal. This oxide coating is integral to the metal, providing superior protection compared to surface coatings like powder coating. Anodized aluminum also offers excellent resistance to wear, UV exposure, and chemicals, making it ideal for architectural and industrial applications.

Key Differences: Powder Coating vs Anodizing

Powder-coated metal features a durable, colored polymer layer applied electrostatically and cured under heat, providing excellent corrosion and impact resistance. Anodized metal undergoes an electrochemical process that thickens the natural oxide layer, enhancing corrosion resistance and surface hardness while retaining the metal's metallic appearance. Powder coating offers a wider range of color options and thicker protective layers, whereas anodizing ensures a more wear-resistant, thin, and uniform finish ideal for aluminum alloys.

Durability Comparison: Powder-Coated vs Anodized Metals

Powder-coated metal offers a thicker, more durable layer of protection against scratches, chipping, and corrosion compared to anodized metal, which provides a thin, chemically bonded oxide layer primarily enhancing corrosion and wear resistance. Anodized metal excels in maintaining metal's natural appearance and increasing surface hardness but is more susceptible to surface scratches that powder coating can better withstand. Industrial applications requiring heavy-duty durability often favor powder coating for its superior resistance to impact and environmental degradation.

Corrosion Resistance: Which Metal Finish is Superior?

Powder-coated metal offers a robust protective layer that resists corrosion by creating a thick, uniform barrier against moisture and environmental elements. Anodized metal enhances corrosion resistance through an electrochemical process that forms a durable oxide layer, particularly effective on aluminum substrates. For extreme corrosion resistance, powder coating excels in harsh conditions, while anodizing provides superior adhesion and durability for lightweight, marine, and architectural applications.

Aesthetic Options: Color and Texture in Powder Coating vs Anodizing

Powder-coated metal offers a broader spectrum of vibrant colors and customizable textures, allowing for matte, glossy, or textured finishes that enhance visual appeal and tactile experience. Anodized metal primarily provides metallic shades with a natural, smooth finish, offering subtle color variations through dyeing but limited textural options. The versatility of powder coating makes it ideal for aesthetic-driven applications demanding diverse color palettes and finishes, while anodizing suits designs favoring a sleek, metallic look with enhanced corrosion resistance.

Application Areas: Where to Use Powder-Coated and Anodized Metals

Powder-coated metal is ideal for outdoor applications such as automotive parts, architectural structures, and playground equipment due to its resistance to corrosion, UV rays, and scratches. Anodized metal suits indoor uses like electronic housings, kitchen appliances, and decorative finishes because of its enhanced surface hardness and improved wear resistance. Both coatings offer durable solutions, but powder coating excels in rugged environments while anodizing is preferred for lightweight, precision components.

Environmental Impact: Powder Coating vs Anodizing

Powder-coated metal reduces environmental impact by minimizing volatile organic compound (VOC) emissions and utilizing nearly all overspray in the process, resulting in less waste compared to traditional liquid paints. Anodized metal, created through an electrochemical process, produces a thin oxide layer that is non-toxic and durable, but it requires significant electricity and generates acidic wastewater that must be carefully treated. Selecting powder coating generally offers a more eco-friendly solution due to lower hazardous waste and energy consumption, while anodizing demands stringent environmental controls to mitigate its chemical runoff.

Choosing the Right Finish: Factors to Consider

Choosing the right finish between powder-coated metal and anodized metal depends on factors such as durability, environmental exposure, and aesthetic preference. Powder coating offers a thick, protective layer resistant to chipping and corrosion, ideal for outdoor and industrial applications, while anodizing enhances aluminum's corrosion resistance with a thinner, more natural finish that maintains metal texture. Consider factors like UV resistance, maintenance requirements, and the specific metal type to ensure optimal performance and longevity.

Powder-Coated Metal vs Anodized Metal Infographic

materialdif.com

materialdif.com