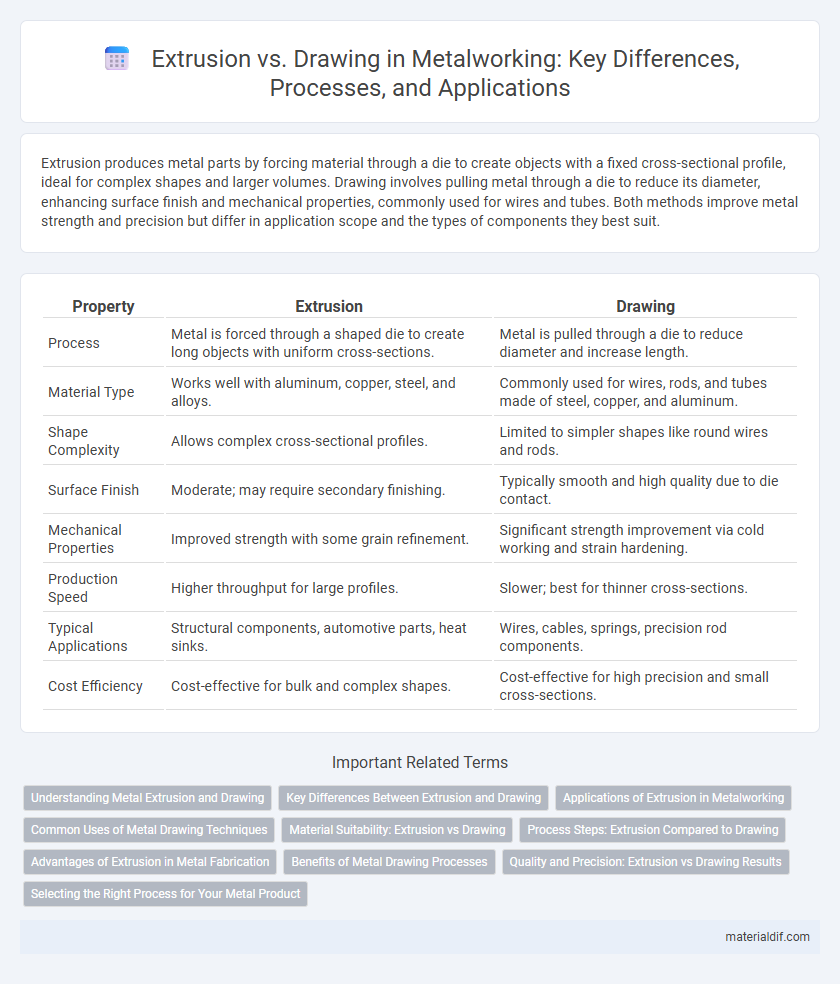

Extrusion produces metal parts by forcing material through a die to create objects with a fixed cross-sectional profile, ideal for complex shapes and larger volumes. Drawing involves pulling metal through a die to reduce its diameter, enhancing surface finish and mechanical properties, commonly used for wires and tubes. Both methods improve metal strength and precision but differ in application scope and the types of components they best suit.

Table of Comparison

| Property | Extrusion | Drawing |

|---|---|---|

| Process | Metal is forced through a shaped die to create long objects with uniform cross-sections. | Metal is pulled through a die to reduce diameter and increase length. |

| Material Type | Works well with aluminum, copper, steel, and alloys. | Commonly used for wires, rods, and tubes made of steel, copper, and aluminum. |

| Shape Complexity | Allows complex cross-sectional profiles. | Limited to simpler shapes like round wires and rods. |

| Surface Finish | Moderate; may require secondary finishing. | Typically smooth and high quality due to die contact. |

| Mechanical Properties | Improved strength with some grain refinement. | Significant strength improvement via cold working and strain hardening. |

| Production Speed | Higher throughput for large profiles. | Slower; best for thinner cross-sections. |

| Typical Applications | Structural components, automotive parts, heat sinks. | Wires, cables, springs, precision rod components. |

| Cost Efficiency | Cost-effective for bulk and complex shapes. | Cost-effective for high precision and small cross-sections. |

Understanding Metal Extrusion and Drawing

Metal extrusion involves forcing heated metal through a die to create long shapes with uniform cross-sections, ideal for producing complex profiles. Metal drawing, by contrast, pulls metal through a die to reduce its diameter and improve surface finish and mechanical properties, commonly used for wires and rods. Both processes alter metal's shape and grain structure, impacting strength, versatility, and application in industries such as automotive and construction.

Key Differences Between Extrusion and Drawing

Extrusion involves forcing heated metal through a die to create objects with uniform cross-sections, while drawing pulls metal through a die to reduce its diameter and improve surface finish. Extrusion can produce complex shapes with varied cross-sections, whereas drawing primarily refines wire, rod, or tube dimensions with enhanced tensile strength. The key differences lie in the metal state (heated for extrusion, usually cold for drawing) and the resultant mechanical properties and applications.

Applications of Extrusion in Metalworking

Extrusion in metalworking is widely used for manufacturing complex cross-sectional profiles such as aluminum window frames, tubing, and heat sinks, offering precise dimensional control and high production rates. This process is ideal for producing long lengths of metal parts with consistent quality, commonly applied in aerospace, automotive, and construction industries. Compared to drawing, extrusion enables the creation of hollow or intricate shapes that are difficult to achieve with traditional wire or rod drawing methods.

Common Uses of Metal Drawing Techniques

Metal drawing techniques are commonly used to create precision wires, rods, and tubes essential for electrical wiring, automotive components, and medical devices. Drawing processes enable the production of high-strength, smooth-surfaced metal parts with controlled dimensions, ideal for engineering and construction applications. This method is especially favored for manufacturing fine gauges and intricate shapes that require excellent tensile properties and surface finish.

Material Suitability: Extrusion vs Drawing

Extrusion is highly suitable for materials with good plasticity such as aluminum, copper, and magnesium alloys, allowing complex cross-sectional shapes to be formed efficiently. Drawing is more effective for metals like steel, stainless steel, and copper, where precise dimensional control and improved mechanical properties through cold working are required. Material grain structure and ductility play crucial roles in determining whether extrusion or drawing is the optimal metal forming process.

Process Steps: Extrusion Compared to Drawing

Extrusion involves forcing heated metal through a die to create long shapes with consistent cross-sections, while drawing pulls the metal through a die to reduce its diameter and increase length. In extrusion, the metal experiences compressive forces and deformation occurs mainly in one direction, whereas drawing applies tensile forces, elongating the material. The extrusion process is typically faster and better suited for complex cross-sectional profiles, whereas drawing offers superior surface finish and dimensional accuracy.

Advantages of Extrusion in Metal Fabrication

Extrusion in metal fabrication offers superior design flexibility, enabling complex cross-sectional profiles that are difficult to achieve with drawing. The process provides enhanced material strength through continuous grain flow aligned with the shape, resulting in improved mechanical properties. Additionally, extrusion supports a wider range of metals and alloys, facilitating efficient production of long, uniform parts with minimal waste.

Benefits of Metal Drawing Processes

Metal drawing processes enhance dimensional accuracy and surface finish, reducing the need for secondary machining operations. These methods improve mechanical properties through strain hardening, increasing tensile strength and hardness. Consistent cross-sectional profiles and tighter tolerances make drawing ideal for producing wire, rods, and tubes in high-volume manufacturing.

Quality and Precision: Extrusion vs Drawing Results

Extrusion produces metal parts with consistent cross-sectional profiles and smooth surface finishes, ensuring high dimensional accuracy and reduced material waste. Drawing achieves superior tensile strength and fine surface detail due to work hardening, providing tighter tolerances and enhanced mechanical properties. Both processes deliver high-quality results, but drawing excels in precision-critical applications requiring exceptional surface quality and strength.

Selecting the Right Process for Your Metal Product

Extrusion shapes metal by forcing it through a die to create long, continuous profiles with uniform cross-sections, making it ideal for complex shapes and lightweight designs. Drawing involves pulling metal through a die to reduce its diameter, enhancing tensile strength and surface finish, which suits wires, rods, and tubes. Choosing between extrusion and drawing depends on desired product geometry, mechanical properties, and production volume requirements for optimal metal fabrication.

Extrusion vs Drawing Infographic

materialdif.com

materialdif.com