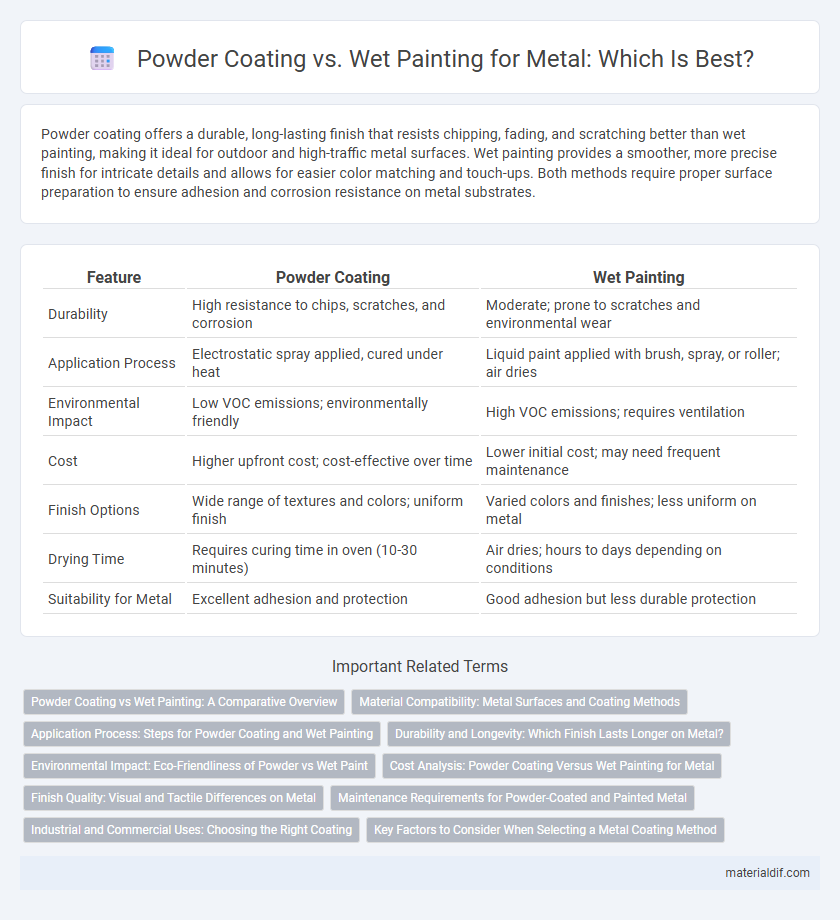

Powder coating offers a durable, long-lasting finish that resists chipping, fading, and scratching better than wet painting, making it ideal for outdoor and high-traffic metal surfaces. Wet painting provides a smoother, more precise finish for intricate details and allows for easier color matching and touch-ups. Both methods require proper surface preparation to ensure adhesion and corrosion resistance on metal substrates.

Table of Comparison

| Feature | Powder Coating | Wet Painting |

|---|---|---|

| Durability | High resistance to chips, scratches, and corrosion | Moderate; prone to scratches and environmental wear |

| Application Process | Electrostatic spray applied, cured under heat | Liquid paint applied with brush, spray, or roller; air dries |

| Environmental Impact | Low VOC emissions; environmentally friendly | High VOC emissions; requires ventilation |

| Cost | Higher upfront cost; cost-effective over time | Lower initial cost; may need frequent maintenance |

| Finish Options | Wide range of textures and colors; uniform finish | Varied colors and finishes; less uniform on metal |

| Drying Time | Requires curing time in oven (10-30 minutes) | Air dries; hours to days depending on conditions |

| Suitability for Metal | Excellent adhesion and protection | Good adhesion but less durable protection |

Powder Coating vs Wet Painting: A Comparative Overview

Powder coating provides a durable and corrosion-resistant finish compared to wet painting, which is more prone to chipping and fading. The electrostatic application of powder coating results in a thicker, uniform layer without solvents, reducing emissions and environmental impact. Wet painting allows for easier touch-ups and color variations but requires longer drying times and more frequent maintenance in industrial metal applications.

Material Compatibility: Metal Surfaces and Coating Methods

Powder coating offers superior adhesion and durability on metal surfaces due to its electrostatic application process, which allows for even coverage on complex geometries and provides resistance to chipping and corrosion. Wet painting, while versatile, may require additional primers or treatment to achieve similar adhesion and protection, especially on metals prone to oxidation such as aluminum or galvanized steel. Choosing the right coating method depends on the metal type, surface preparation, and desired performance characteristics like environmental resistance and finish quality.

Application Process: Steps for Powder Coating and Wet Painting

Powder coating begins with surface preparation, including cleaning and abrasive blasting, followed by electrostatically applying dry powder to the metal substrate, and then curing in an oven to form a durable finish. Wet painting involves multiple steps: surface cleaning, applying primer, followed by one or more layers of liquid paint using spray guns or brushes, and finally air drying or oven curing depending on the paint type. Both processes require precise surface preparation for optimal adhesion and corrosion resistance but differ significantly in application techniques and curing requirements.

Durability and Longevity: Which Finish Lasts Longer on Metal?

Powder coating exhibits superior durability and longevity on metal surfaces due to its thick, uniform finish that resists chipping, scratching, and fading better than wet painting. Unlike wet paint, which can degrade over time from UV exposure and moisture, powder coating creates a tough, corrosion-resistant barrier that extends the lifespan of metal objects. Studies show powder-coated finishes can last 10-20 years with minimal maintenance, outperforming traditional wet paint in harsh environmental conditions.

Environmental Impact: Eco-Friendliness of Powder vs Wet Paint

Powder coating significantly reduces environmental impact by producing minimal volatile organic compounds (VOCs) and generating less hazardous waste compared to traditional wet painting, which commonly emits high VOC levels harmful to air quality. The overspray in powder coating can be recycled up to 95%, enhancing material efficiency and minimizing landfill contributions, whereas wet paint waste often requires special disposal to prevent soil and water contamination. Powder coating's energy-efficient curing process further lowers carbon emissions, promoting a more sustainable industrial finish for metal surfaces.

Cost Analysis: Powder Coating Versus Wet Painting for Metal

Powder coating offers a cost-effective solution compared to wet painting for metal due to lower material waste and reduced labor time, with average savings of 20-30% on large-scale projects. Wet painting involves higher expenses from solvent-based materials and extended drying times, increasing production costs and energy consumption. Maintenance and durability advantages of powder coating further reduce long-term costs through less frequent touch-ups and refinishing.

Finish Quality: Visual and Tactile Differences on Metal

Powder coating creates a thicker, more durable finish on metal surfaces, offering superior resistance to chipping, fading, and corrosion compared to wet painting. The textured tactile feel of powder coating is smoother and more uniform, while wet paint often results in a glossier but less consistent surface prone to unevenness. Metal objects treated with powder coating maintain their vibrant color and finish quality longer under harsh conditions, making them ideal for outdoor or industrial applications.

Maintenance Requirements for Powder-Coated and Painted Metal

Powder-coated metal surfaces require minimal maintenance, as their durable, corrosion-resistant finish resists chipping, fading, and scratching better than traditional wet paint. Wet painted metal often needs more frequent touch-ups due to its susceptibility to cracking, peeling, and environmental wear, especially in outdoor or harsh conditions. Regular cleaning with mild detergents is essential for both finishes, but powder coating reduces long-term upkeep costs by maintaining appearance and protection with less effort.

Industrial and Commercial Uses: Choosing the Right Coating

Powder coating offers superior durability, corrosion resistance, and environmental benefits, making it ideal for industrial machinery, automotive parts, and commercial metal structures exposed to harsh conditions. Wet painting provides greater color variety and easier touch-up options, suited for projects requiring frequent maintenance or aesthetic flexibility in commercial interiors. Selecting the right coating depends on factors like exposure environment, longevity requirements, and regulatory compliance for safety and environmental standards.

Key Factors to Consider When Selecting a Metal Coating Method

Powder coating provides a durable, corrosion-resistant finish ideal for outdoor metal applications, while wet painting offers versatility in color and easier touch-ups. Surface preparation, environmental regulations, application cost, and desired finish quality are critical factors influencing the choice between these methods. Consider equipment availability and curing time alongside the metal type to optimize coating performance and longevity.

Powder Coating vs Wet Painting Infographic

materialdif.com

materialdif.com