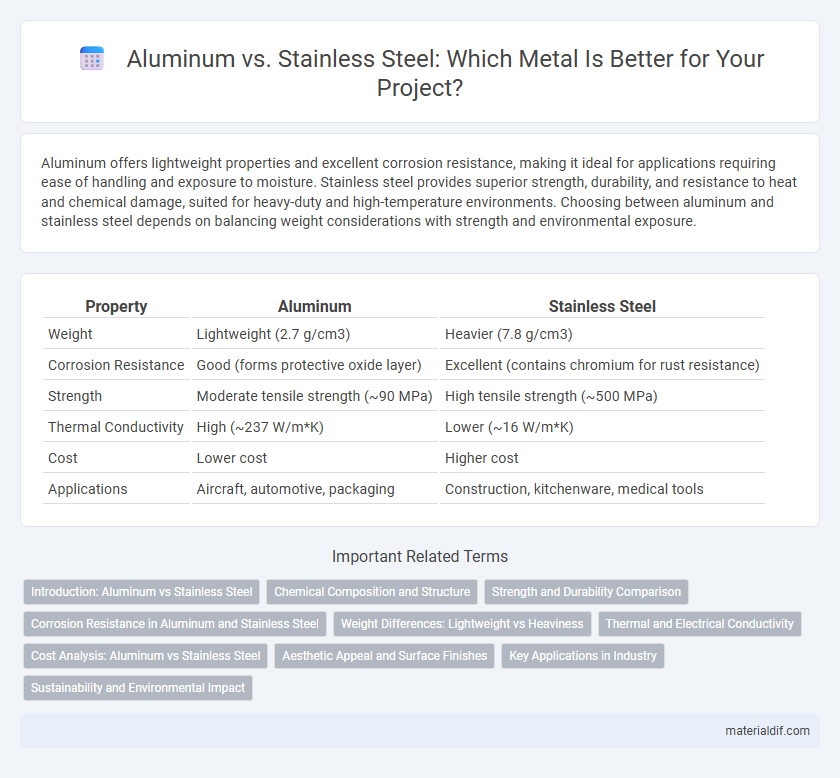

Aluminum offers lightweight properties and excellent corrosion resistance, making it ideal for applications requiring ease of handling and exposure to moisture. Stainless steel provides superior strength, durability, and resistance to heat and chemical damage, suited for heavy-duty and high-temperature environments. Choosing between aluminum and stainless steel depends on balancing weight considerations with strength and environmental exposure.

Table of Comparison

| Property | Aluminum | Stainless Steel |

|---|---|---|

| Weight | Lightweight (2.7 g/cm3) | Heavier (7.8 g/cm3) |

| Corrosion Resistance | Good (forms protective oxide layer) | Excellent (contains chromium for rust resistance) |

| Strength | Moderate tensile strength (~90 MPa) | High tensile strength (~500 MPa) |

| Thermal Conductivity | High (~237 W/m*K) | Lower (~16 W/m*K) |

| Cost | Lower cost | Higher cost |

| Applications | Aircraft, automotive, packaging | Construction, kitchenware, medical tools |

Introduction: Aluminum vs Stainless Steel

Aluminum and stainless steel are two widely used metals in manufacturing and construction, each offering distinct properties suited for different applications. Aluminum is lightweight, corrosion-resistant, and highly malleable, making it ideal for aerospace, automotive, and packaging industries. Stainless steel, known for its high strength, durability, and resistance to rust and staining, is commonly used in medical instruments, kitchenware, and architectural structures.

Chemical Composition and Structure

Aluminum features a lightweight, FCC (face-centered cubic) crystal structure primarily composed of pure Al atoms, contributing to excellent corrosion resistance and conductivity. Stainless steel consists mainly of iron, chromium (typically 10.5% to 20%), and varying amounts of nickel and carbon, forming a BCC (body-centered cubic) or FCC crystalline structure that enhances strength and corrosion resistance through the formation of a passive chromium oxide layer. The chemical composition differences directly influence mechanical properties and corrosion behavior, with aluminum's oxide layer providing natural corrosion protection, whereas stainless steel relies on alloying elements for durability and resilience in harsh environments.

Strength and Durability Comparison

Aluminum offers a high strength-to-weight ratio, making it ideal for applications requiring lightweight materials with moderate durability. Stainless steel exhibits superior strength and exceptional corrosion resistance, providing long-lasting durability in harsh environments. While aluminum is prone to surface wear and dents, stainless steel maintains structural integrity under heavy loads and extreme conditions.

Corrosion Resistance in Aluminum and Stainless Steel

Aluminum exhibits excellent corrosion resistance due to a natural oxide layer that forms instantly upon exposure to air, protecting the metal from further oxidation and environmental damage. Stainless steel's corrosion resistance derives from its high chromium content, which enables the formation of a stable, passive oxide layer that resists rust and chemical attack even in harsh environments. While aluminum performs well in atmospheric and mildly corrosive conditions, stainless steel offers superior durability in marine, acidic, and high-temperature applications.

Weight Differences: Lightweight vs Heaviness

Aluminum is significantly lighter than stainless steel, with a density approximately 2.7 g/cm3 compared to stainless steel's density of around 8 g/cm3, making aluminum nearly three times less dense. This weight difference makes aluminum an ideal choice for applications demanding lightweight materials, such as aerospace and automotive industries. Stainless steel, while heavier, offers superior strength and durability, making it suitable for structural components and environments requiring corrosion resistance.

Thermal and Electrical Conductivity

Aluminum exhibits higher thermal conductivity, around 205 W/m*K, compared to stainless steel's 15 W/m*K, making it more efficient for heat dissipation in applications like heat exchangers. In electrical conductivity, aluminum surpasses stainless steel with a conductivity of approximately 37.7 MS/m, whereas stainless steel is significantly lower, around 1.45 MS/m, limiting its use in electrical applications. These properties make aluminum ideal for electrical wiring and thermal management, while stainless steel is preferred where strength and corrosion resistance outweigh conductivity.

Cost Analysis: Aluminum vs Stainless Steel

Aluminum offers a lower initial cost compared to stainless steel, making it a budget-friendly option for projects with tight financial constraints. Stainless steel, despite its higher upfront price, provides superior durability and corrosion resistance, potentially reducing long-term maintenance and replacement expenses. Evaluating the total cost of ownership highlights aluminum for cost-efficiency in lightweight applications, while stainless steel excels in environments demanding robustness and longevity.

Aesthetic Appeal and Surface Finishes

Aluminum offers a lightweight option with a naturally matte, silver-gray finish that can be anodized to enhance corrosion resistance and introduce vibrant colors, making it ideal for modern, sleek designs. Stainless steel provides a polished, shiny surface that resists tarnishing and is available in various finishes like brushed, mirror, and satin, lending a sophisticated and durable aesthetic suitable for both industrial and contemporary applications. Both metals enable diverse surface textures, but stainless steel typically delivers a more striking visual impact due to its reflective qualities and resistance to surface wear.

Key Applications in Industry

Aluminum's lightweight property makes it ideal for aerospace, automotive, and packaging industries where weight reduction enhances efficiency and fuel economy. Stainless steel's exceptional corrosion resistance and strength are crucial for medical equipment, food processing, and construction sectors demanding durability and hygiene. Both metals serve distinct industrial applications by balancing performance requirements with material characteristics.

Sustainability and Environmental Impact

Aluminum offers a lightweight, highly recyclable option with lower energy consumption in recycling processes compared to stainless steel, making it favorable for sustainability efforts. Stainless steel, known for its durability and corrosion resistance, has a longer lifespan which can reduce the frequency of replacement and waste generation. Both metals contribute to environmental impact reduction, but aluminum's ease of recycling and lower carbon footprint during manufacturing position it as a more environmentally sustainable material choice.

Aluminum vs Stainless Steel Infographic

materialdif.com

materialdif.com