Powder coating and galvanizing both protect metal surfaces from corrosion but differ in application and durability. Powder coating involves applying a dry, colored powder that is cured under heat to form a hard, smooth finish, ideal for aesthetic appeal and resistance to chipping. Galvanizing coats metal with a layer of zinc, providing superior corrosion resistance especially in harsh outdoor environments, making it suitable for structural steel and industrial applications.

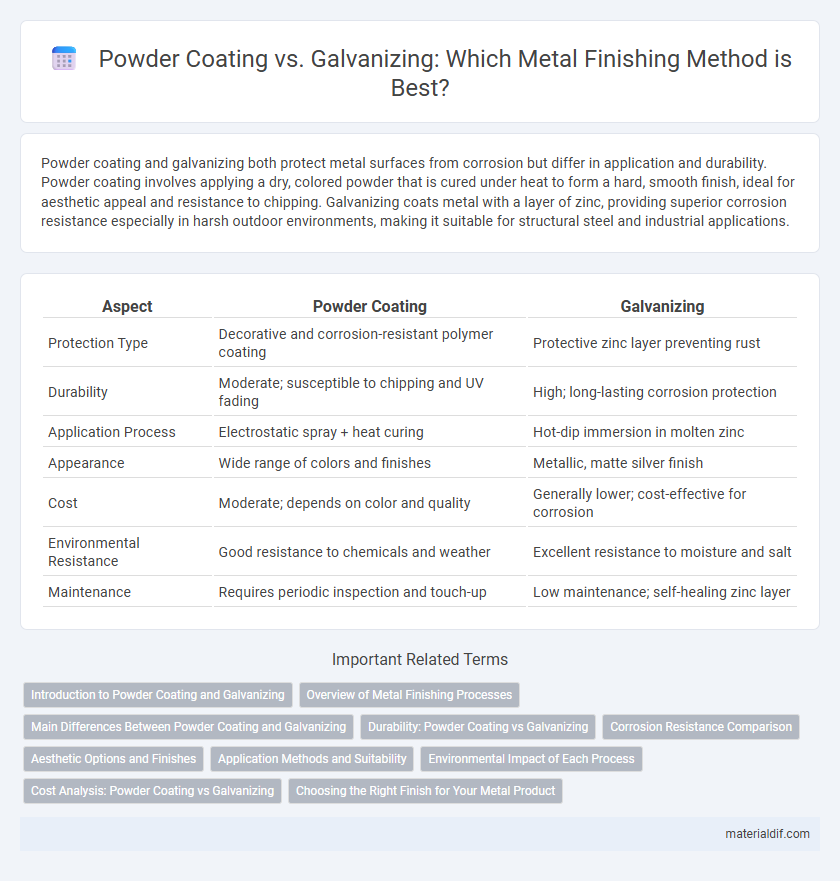

Table of Comparison

| Aspect | Powder Coating | Galvanizing |

|---|---|---|

| Protection Type | Decorative and corrosion-resistant polymer coating | Protective zinc layer preventing rust |

| Durability | Moderate; susceptible to chipping and UV fading | High; long-lasting corrosion protection |

| Application Process | Electrostatic spray + heat curing | Hot-dip immersion in molten zinc |

| Appearance | Wide range of colors and finishes | Metallic, matte silver finish |

| Cost | Moderate; depends on color and quality | Generally lower; cost-effective for corrosion |

| Environmental Resistance | Good resistance to chemicals and weather | Excellent resistance to moisture and salt |

| Maintenance | Requires periodic inspection and touch-up | Low maintenance; self-healing zinc layer |

Introduction to Powder Coating and Galvanizing

Powder coating is a dry finishing process where powdered paint is electrostatically applied and cured under heat to form a durable, protective layer on metal surfaces. Galvanizing involves coating metal, typically steel or iron, with a layer of zinc to prevent rust and corrosion through a chemical bond. Both methods enhance metal durability but differ in application technique and protective properties.

Overview of Metal Finishing Processes

Powder coating and galvanizing are key metal finishing processes designed to enhance durability and corrosion resistance. Powder coating applies a dry, electrostatically charged powder that is cured under heat, creating a hard, protective layer ideal for aesthetic and environmental resistance. Galvanizing involves immersing steel in molten zinc, forming a robust, corrosion-resistant zinc-iron alloy coating that protects metal in harsh outdoor environments.

Main Differences Between Powder Coating and Galvanizing

Powder coating provides a durable, color-rich finish using electrostatically applied dry paint that cures under heat, protecting metals primarily through a protective polymer layer. Galvanizing involves coating steel or iron with a zinc layer through hot-dip or electroplating processes, offering superior corrosion resistance by sacrificially corroding the zinc before the base metal. While powder coating excels in aesthetic versatility and surface hardness, galvanizing is preferred for long-term outdoor durability and protection in harsh environments.

Durability: Powder Coating vs Galvanizing

Powder coating provides a durable, protective layer that resists chipping, scratching, and fading, making it ideal for aesthetic metal finishes with long-term color retention. Galvanizing offers superior corrosion resistance by forming a robust zinc coating that protects steel from rust, especially in harsh outdoor environments. Both methods enhance metal durability, but galvanizing excels in preventing rust, while powder coating delivers enhanced surface toughness and visual appeal.

Corrosion Resistance Comparison

Powder coating provides a durable, thick protective layer that resists chipping, scratching, and fading, enhancing corrosion resistance on metal surfaces. Galvanizing involves applying a zinc coating that offers sacrificial protection by corroding first, effectively preventing rust over extended periods, especially in harsh environments. While powder coating excels in aesthetic appeal and surface protection, galvanizing ensures superior long-term corrosion resistance, particularly for outdoor and industrial applications.

Aesthetic Options and Finishes

Powder coating offers a wide range of vibrant colors and smooth, uniform finishes that enhance the visual appeal and customization of metal surfaces. Galvanizing primarily provides a zinc coating that results in a matte, silver-gray appearance focused on corrosion resistance rather than decorative variety. Combining galvanizing with powder coating can maximize both durability and aesthetic versatility for metal products.

Application Methods and Suitability

Powder coating involves applying a dry, electrostatically charged powder which is then cured under heat to form a durable, decorative finish, making it ideal for aesthetic and corrosion-resistant applications on complex shapes. Galvanizing, typically achieved through hot-dip immersion in molten zinc, provides a robust, long-lasting corrosion barrier especially suited for structural steel exposed to harsh outdoor environments. Selection between powder coating and galvanizing depends on the required durability, environmental exposure, and the metal's intended use, with powder coating favored for appearance and galvanizing for heavy-duty protection.

Environmental Impact of Each Process

Powder coating offers a lower environmental impact by producing minimal volatile organic compounds (VOCs) and generating less hazardous waste compared to traditional liquid paints. Galvanizing involves applying a zinc layer through hot-dip or electro-galvanizing, which can release zinc runoff and emit greenhouse gases during the heating process. Choosing powder coating reduces VOC emissions and limits toxic waste, whereas galvanizing provides longer metal corrosion protection but requires careful management of zinc waste to prevent soil and water contamination.

Cost Analysis: Powder Coating vs Galvanizing

Powder coating typically offers a lower upfront cost compared to galvanizing, especially for small to medium-sized metal parts, due to simpler application processes and less material usage; however, galvanizing provides long-term cost savings by offering superior corrosion resistance and reduced maintenance expenses. The lifespan of galvanized steel often exceeds powder-coated finishes in harsh environments, minimizing the need for frequent recoating or touch-ups, which influences total cost of ownership. Budget considerations must weigh initial investment against durability and environmental conditions to determine the more cost-effective protective method.

Choosing the Right Finish for Your Metal Product

Powder coating offers a durable, colorful finish that resists chipping, scratching, and fading, making it ideal for aesthetic metal products exposed to moderate environmental stress. Galvanizing provides superior corrosion resistance through a zinc coating, which is essential for metal components used in harsh, outdoor, or industrial environments. Selecting between powder coating and galvanizing depends on factors such as desired appearance, environmental exposure, and longevity requirements of the metal product.

Powder Coating vs Galvanizing Infographic

materialdif.com

materialdif.com