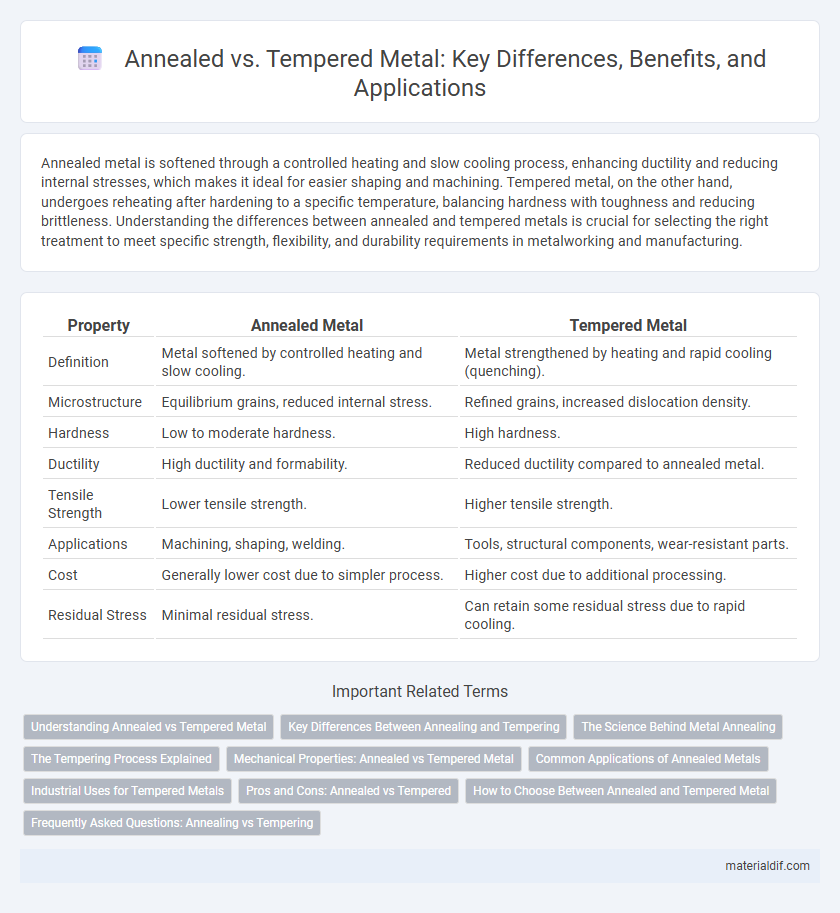

Annealed metal is softened through a controlled heating and slow cooling process, enhancing ductility and reducing internal stresses, which makes it ideal for easier shaping and machining. Tempered metal, on the other hand, undergoes reheating after hardening to a specific temperature, balancing hardness with toughness and reducing brittleness. Understanding the differences between annealed and tempered metals is crucial for selecting the right treatment to meet specific strength, flexibility, and durability requirements in metalworking and manufacturing.

Table of Comparison

| Property | Annealed Metal | Tempered Metal |

|---|---|---|

| Definition | Metal softened by controlled heating and slow cooling. | Metal strengthened by heating and rapid cooling (quenching). |

| Microstructure | Equilibrium grains, reduced internal stress. | Refined grains, increased dislocation density. |

| Hardness | Low to moderate hardness. | High hardness. |

| Ductility | High ductility and formability. | Reduced ductility compared to annealed metal. |

| Tensile Strength | Lower tensile strength. | Higher tensile strength. |

| Applications | Machining, shaping, welding. | Tools, structural components, wear-resistant parts. |

| Cost | Generally lower cost due to simpler process. | Higher cost due to additional processing. |

| Residual Stress | Minimal residual stress. | Can retain some residual stress due to rapid cooling. |

Understanding Annealed vs Tempered Metal

Annealed metal undergoes a controlled heating and slow cooling process to reduce hardness and increase ductility, making it easier to work with and shape. Tempered metal is first quenched to harden it, then reheated to a lower temperature and cooled to achieve a balance of hardness, strength, and toughness. Understanding the differences in heat treatment processes is essential for selecting the right metal properties for applications such as tooling, structural components, or manufacturing.

Key Differences Between Annealing and Tempering

Annealing involves heating metal to a specific temperature and then cooling it slowly to soften the material, improve ductility, and relieve internal stresses. Tempering is performed after quenching, where the metal is reheated to a lower temperature and cooled to enhance toughness and reduce brittleness without significantly decreasing hardness. The primary distinction lies in their heat treatment goals: annealing aims to increase malleability and reduce hardness, while tempering balances hardness and toughness to optimize mechanical properties for functional use.

The Science Behind Metal Annealing

Metal annealing involves heating a metal to a specific temperature and then slowly cooling it to remove internal stresses and increase ductility by promoting atomic diffusion and recrystallization. This process alters the metal's microstructure, reducing dislocations and defects that cause brittleness, resulting in improved malleability and workability. In contrast, tempered metal undergoes rapid cooling to enhance hardness and strength by creating a fine balance between toughness and brittleness through controlled microstructural changes.

The Tempering Process Explained

Tempering is a heat treatment process that improves the toughness of metal after it has been hardened through quenching, reducing brittleness while maintaining strength and hardness. The metal is heated to a temperature below its critical point, typically between 150degC and 650degC, and then cooled slowly to relieve internal stresses and refine the microstructure. Tempered steel exhibits a balanced combination of hardness, ductility, and impact resistance, making it suitable for tools, automotive components, and structural applications.

Mechanical Properties: Annealed vs Tempered Metal

Annealed metal exhibits increased ductility and reduced hardness, making it easier to machine and shape, while tempered metal offers enhanced strength and toughness due to controlled heat treatment. The annealing process softens the metal by relieving internal stresses, resulting in lower tensile strength compared to tempered metal, which is heat-treated and then quenched to achieve improved mechanical performance. Tempered metals typically have higher yield strength and fatigue resistance, making them suitable for applications requiring durability and wear resistance.

Common Applications of Annealed Metals

Annealed metals are widely used in applications requiring enhanced ductility and reduced hardness, such as in electrical wiring, metal forming, and automotive panels. Their improved machinability and flexibility make them ideal for manufacturing complex parts and components subjected to bending or shaping processes. Common industries utilizing annealed metals include aerospace, construction, and household appliances.

Industrial Uses for Tempered Metals

Tempered metals, known for their enhanced strength and durability, are widely used in industrial applications requiring resistance to wear and stress, such as automotive components, aerospace parts, and heavy machinery. The tempering process improves the metal's toughness, making it ideal for tools, structural supports, and safety equipment subjected to high impact and fatigue conditions. Industrial sectors rely on tempered metals to ensure performance reliability and longevity under demanding operational environments.

Pros and Cons: Annealed vs Tempered

Annealed metal offers enhanced ductility and reduced hardness, making it easier to machine and form but sacrificing tensile strength and wear resistance. Tempered metal provides increased strength, toughness, and resistance to fatigue due to controlled heat treatment but can be less malleable and more prone to cracking under extreme stress. Choosing between annealed and tempered depends on the specific balance required between machinability and mechanical performance in applications such as automotive parts or structural components.

How to Choose Between Annealed and Tempered Metal

Choosing between annealed and tempered metal depends on the application's need for strength versus ductility. Annealed metal offers increased softness and flexibility due to its heat treatment process, making it ideal for bending or forming tasks. Tempered metal provides enhanced hardness and tensile strength, suitable for components requiring durability and resistance to wear.

Frequently Asked Questions: Annealing vs Tempering

Annealing softens metal by heating it to a specific temperature and allowing it to cool slowly, enhancing ductility and reducing hardness for easier machining. Tempering involves reheating quenched metal below its critical point to decrease brittleness while maintaining hardness, improving toughness. The choice between annealed and tempered metals depends on the desired balance of strength, flexibility, and durability in applications such as aerospace, automotive, and tooling industries.

Annealed vs Tempered Infographic

materialdif.com

materialdif.com