Solid metal consists of a single pure element with uniform physical and chemical properties, providing consistent strength and conductivity. Metal alloys combine two or more elements, enhancing properties such as hardness, corrosion resistance, and tensile strength beyond those of solid metals. Selecting between solid metal and metal alloy depends on the specific application requirements, including durability and environmental exposure.

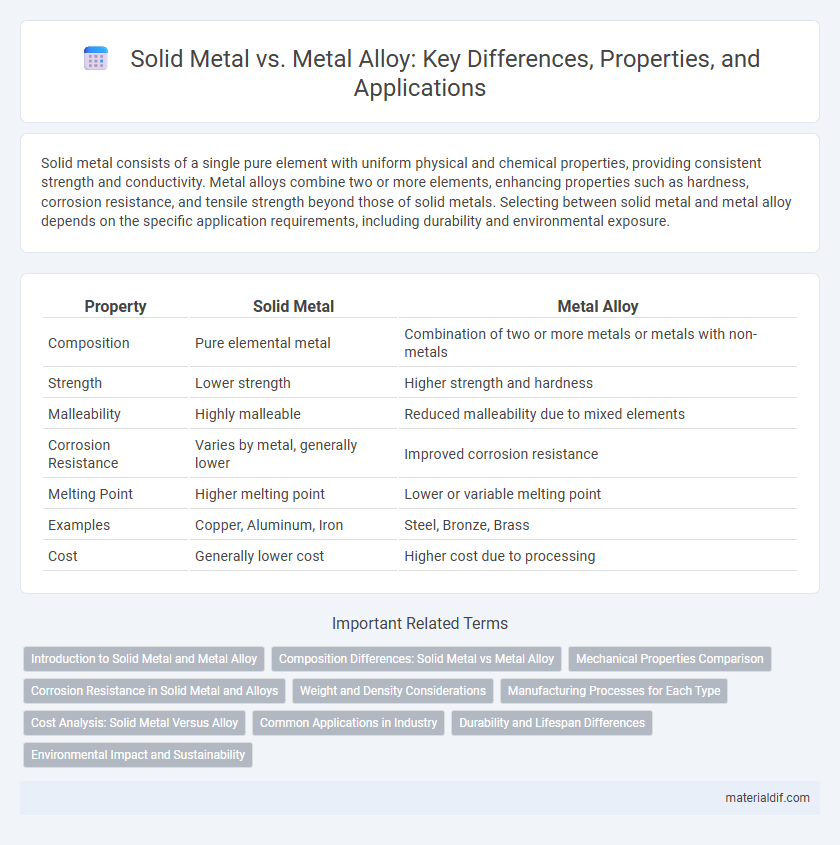

Table of Comparison

| Property | Solid Metal | Metal Alloy |

|---|---|---|

| Composition | Pure elemental metal | Combination of two or more metals or metals with non-metals |

| Strength | Lower strength | Higher strength and hardness |

| Malleability | Highly malleable | Reduced malleability due to mixed elements |

| Corrosion Resistance | Varies by metal, generally lower | Improved corrosion resistance |

| Melting Point | Higher melting point | Lower or variable melting point |

| Examples | Copper, Aluminum, Iron | Steel, Bronze, Brass |

| Cost | Generally lower cost | Higher cost due to processing |

Introduction to Solid Metal and Metal Alloy

Solid metal consists of pure elements with a uniform atomic structure, offering high strength, excellent conductivity, and predictable mechanical properties. Metal alloys are engineered by combining two or more metals or elements to enhance specific characteristics such as corrosion resistance, hardness, and flexibility. Understanding the differences between solid metals and metal alloys is crucial for selecting appropriate materials in manufacturing and engineering applications.

Composition Differences: Solid Metal vs Metal Alloy

Solid metal consists of a single pure element with uniform atomic structure, providing consistent physical and chemical properties. Metal alloys are composed of two or more elements, typically metals, blended to enhance strength, corrosion resistance, or durability by altering the microstructure. The composition differences between solid metals and metal alloys directly influence their mechanical behavior, thermal conductivity, and applications in industries such as aerospace and automotive engineering.

Mechanical Properties Comparison

Solid metals exhibit consistent mechanical properties such as high tensile strength, ductility, and thermal conductivity, making them ideal for applications requiring uniform performance. Metal alloys offer enhanced mechanical properties like improved hardness, corrosion resistance, and fatigue strength due to the combination of multiple elements altering their microstructure. The choice between solid metals and alloys depends on the specific mechanical requirements, with alloys often preferred for components subject to wear and stress.

Corrosion Resistance in Solid Metal and Alloys

Solid metals often exhibit lower corrosion resistance compared to metal alloys due to their uniform composition, which lacks the protective properties introduced by alloying elements. Metal alloys, such as stainless steel or bronze, incorporate elements like chromium and nickel that form passive oxide layers, significantly enhancing their resistance to oxidation and corrosion. The presence of multiple metals in alloys creates galvanic effects and microstructural barriers that reduce corrosion rates, making alloys preferable for environments exposed to moisture and chemical agents.

Weight and Density Considerations

Solid metals typically exhibit higher density and weight compared to metal alloys, as alloys are engineered by combining different metals or non-metal elements to reduce mass without sacrificing strength. The density of a solid metal such as pure iron or copper often surpasses that of its alloy counterparts, which may include lighter elements like aluminum or magnesium to achieve a lighter but durable material. Weight considerations are critical in industries such as aerospace or automotive manufacturing, where using metal alloys optimizes performance by balancing strength with reduced structural mass.

Manufacturing Processes for Each Type

Solid metals undergo manufacturing processes such as casting, forging, and machining, which emphasize shaping pure elemental materials with consistent mechanical properties. Metal alloys require specialized techniques like alloying and heat treatment to enhance strength, corrosion resistance, and durability during manufacturing stages. Advanced processes including powder metallurgy and additive manufacturing enable precise control over microstructure in both solid metals and metal alloys.

Cost Analysis: Solid Metal Versus Alloy

Solid metals typically incur higher raw material costs due to their purity and processing demands, while metal alloys often benefit from reduced expenses by combining base metals with less costly elements. The cost efficiency of alloys improves further through enhanced mechanical properties, which can lead to decreased material usage and lower manufacturing costs. Evaluating total ownership costs, including production, machining, and maintenance, reveals that alloys frequently offer better economic advantages over solid metals in industrial applications.

Common Applications in Industry

Solid metals like steel and aluminum are widely used in construction, automotive manufacturing, and aerospace due to their strength, durability, and ease of fabrication. Metal alloys, such as stainless steel and brass, find extensive applications in medical devices, electrical components, and machinery because of their enhanced corrosion resistance, conductivity, and tailored mechanical properties. Industrial sectors prioritize metal alloys for specialized performance requirements, while solid metals serve as fundamental materials for structural integrity and load-bearing applications.

Durability and Lifespan Differences

Solid metal typically exhibits higher durability due to its uniform atomic structure, resulting in greater resistance to wear and corrosion compared to metal alloys. Metal alloys combine different elements to enhance specific properties such as strength, flexibility, and resistance to fatigue, often extending the overall lifespan under dynamic or harsh environmental conditions. In applications requiring sustained mechanical performance and toughness, metal alloys generally outperform solid metals by balancing hardness and ductility for improved longevity.

Environmental Impact and Sustainability

Solid metals like pure aluminum and copper generally require less energy for recycling compared to metal alloys, reducing their overall environmental footprint. Metal alloys, such as steel mixed with chromium or nickel, often involve more complex extraction and processing methods that increase carbon emissions and energy consumption. Choosing solid metals over alloys can enhance material efficiency and promote sustainability by minimizing resource depletion and facilitating easier recycling.

Solid Metal vs Metal Alloy Infographic

materialdif.com

materialdif.com