Alloy steel contains additional elements like chromium, nickel, and molybdenum, enhancing its strength, hardness, and resistance to corrosion compared to mild steel, which primarily consists of iron with a low carbon content. Mild steel is easier to weld and shape, making it ideal for construction and automotive applications, while alloy steel is preferred for high-stress environments and tools requiring durability. The choice between alloy steel and mild steel depends on the specific mechanical properties and performance requirements of the project.

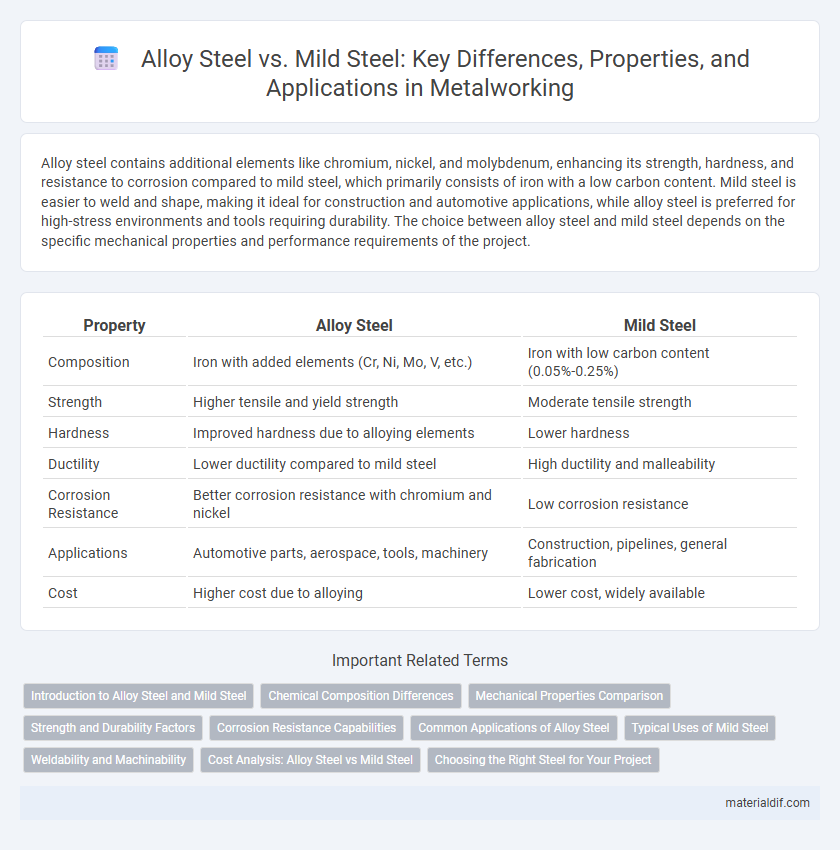

Table of Comparison

| Property | Alloy Steel | Mild Steel |

|---|---|---|

| Composition | Iron with added elements (Cr, Ni, Mo, V, etc.) | Iron with low carbon content (0.05%-0.25%) |

| Strength | Higher tensile and yield strength | Moderate tensile strength |

| Hardness | Improved hardness due to alloying elements | Lower hardness |

| Ductility | Lower ductility compared to mild steel | High ductility and malleability |

| Corrosion Resistance | Better corrosion resistance with chromium and nickel | Low corrosion resistance |

| Applications | Automotive parts, aerospace, tools, machinery | Construction, pipelines, general fabrication |

| Cost | Higher cost due to alloying | Lower cost, widely available |

Introduction to Alloy Steel and Mild Steel

Alloy steel is a type of steel alloyed with various elements like chromium, nickel, and molybdenum to enhance mechanical properties such as strength, hardness, and corrosion resistance. Mild steel, also known as low carbon steel, contains a low percentage of carbon, typically around 0.05% to 0.25%, making it more ductile and easier to weld and shape. Both alloy steel and mild steel are widely used in construction, automotive, and manufacturing industries due to their distinct material characteristics and application versatility.

Chemical Composition Differences

Alloy steel contains a variety of alloying elements such as chromium, nickel, molybdenum, and vanadium, which enhance properties like strength, hardness, and corrosion resistance. Mild steel, also known as low carbon steel, primarily consists of iron with a carbon content typically between 0.05% and 0.25%, resulting in lower strength and hardness but greater ductility. The chemical composition differences significantly affect mechanical properties, with alloy steel offering improved performance in demanding applications due to its tailored elemental makeup.

Mechanical Properties Comparison

Alloy steel exhibits higher tensile strength, hardness, and wear resistance compared to mild steel due to the addition of elements like chromium, nickel, and vanadium, which enhance its mechanical properties. Mild steel, composed primarily of iron with a low carbon content, offers greater ductility and weldability but lower strength and toughness than alloy steel. The superior mechanical performance of alloy steel makes it suitable for high-stress applications such as automotive components and industrial machinery, whereas mild steel is preferred for structural uses requiring flexibility and ease of fabrication.

Strength and Durability Factors

Alloy steel offers higher strength and superior durability due to the presence of elements like chromium, nickel, and molybdenum, which enhance hardness and resistance to wear and corrosion. Mild steel, primarily composed of iron with a low carbon content, provides good ductility and weldability but lacks the enhanced mechanical properties of alloy steel. The enhanced tensile strength of alloy steel makes it ideal for demanding applications, while mild steel is suited for general construction requiring moderate strength.

Corrosion Resistance Capabilities

Alloy steel exhibits superior corrosion resistance compared to mild steel due to the presence of elements such as chromium, nickel, and molybdenum, which form a protective oxide layer preventing rust. Mild steel, primarily composed of iron with low carbon content, lacks these alloying elements and therefore corrodes more rapidly when exposed to moisture and environmental agents. The enhanced corrosion resistance of alloy steel makes it ideal for applications requiring durability in harsh or corrosive environments.

Common Applications of Alloy Steel

Alloy steel is widely used in automotive components, machinery parts, and structural applications due to its enhanced strength, toughness, and resistance to wear compared to mild steel. It plays a crucial role in manufacturing tools, pipelines, and construction equipment that require superior mechanical properties and corrosion resistance. Common alloying elements like chromium, nickel, and molybdenum improve alloy steel's performance in high-stress environments, making it ideal for aerospace and heavy-duty industrial uses.

Typical Uses of Mild Steel

Mild steel is commonly used in construction, automotive manufacturing, and household appliances due to its excellent weldability, ductility, and affordability. Its typical applications include structural beams, pipelines, and automotive body panels where moderate strength and flexibility are essential. Compared to alloy steel, mild steel is preferred for projects requiring ease of machining and mass production with lower cost materials.

Weldability and Machinability

Alloy steel offers enhanced weldability due to its chemical composition, which allows for higher strength and resistance to heat-affected zones compared to mild steel. Mild steel, with its low carbon content, provides superior machinability, making it easier to cut, shape, and drill without excessive tool wear. Selecting between alloy steel and mild steel depends on the balance needed between weld integrity and ease of machining for specific industrial applications.

Cost Analysis: Alloy Steel vs Mild Steel

Alloy steel generally costs more than mild steel due to its enhanced properties and additional alloying elements such as chromium, nickel, and molybdenum, which increase material and production expenses. Mild steel, primarily composed of iron with low carbon content, offers a cost-effective solution for applications that do not require high strength or corrosion resistance. The selection between alloy steel and mild steel hinges on balancing initial material cost against performance benefits and long-term maintenance expenditures.

Choosing the Right Steel for Your Project

Alloy steel offers enhanced strength, corrosion resistance, and durability due to its added elements like chromium, nickel, and molybdenum, making it ideal for high-stress applications. Mild steel, characterized by its low carbon content, provides excellent machinability and weldability, suitable for structural components and general fabrication where cost efficiency is a priority. Selecting the right steel depends on project demands such as load requirements, environmental exposure, and budget constraints to ensure optimal performance and longevity.

Alloy Steel vs Mild Steel Infographic

materialdif.com

materialdif.com