Stainless steel offers superior corrosion resistance due to its chromium content, making it ideal for environments exposed to moisture and chemicals. Carbon steel provides greater strength and hardness, making it suitable for heavy-duty applications where wear resistance is crucial. Choosing between stainless steel and carbon steel depends on balancing durability requirements with environmental factors and maintenance needs.

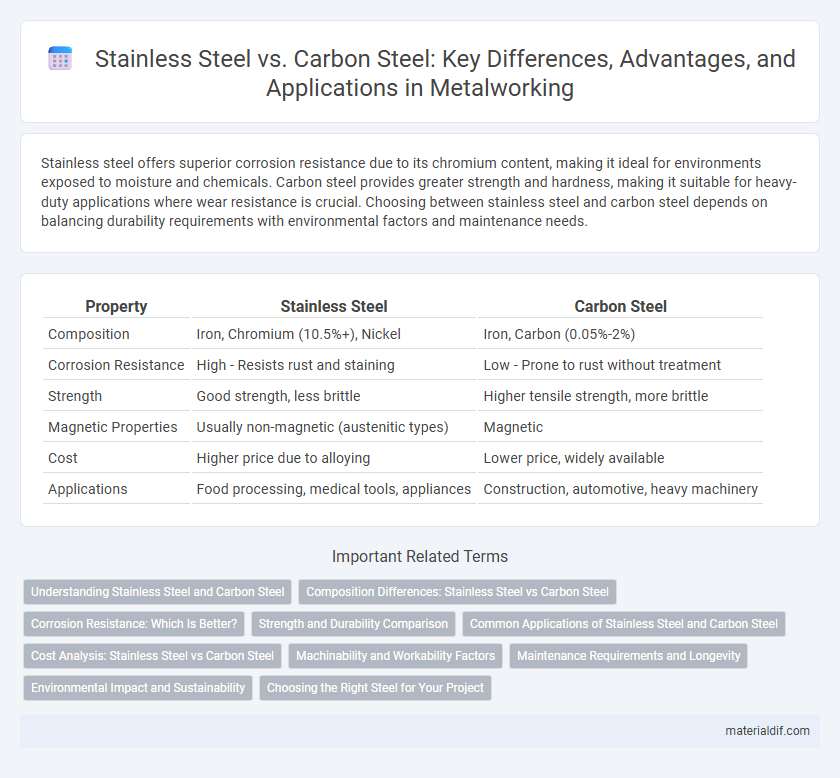

Table of Comparison

| Property | Stainless Steel | Carbon Steel |

|---|---|---|

| Composition | Iron, Chromium (10.5%+), Nickel | Iron, Carbon (0.05%-2%) |

| Corrosion Resistance | High - Resists rust and staining | Low - Prone to rust without treatment |

| Strength | Good strength, less brittle | Higher tensile strength, more brittle |

| Magnetic Properties | Usually non-magnetic (austenitic types) | Magnetic |

| Cost | Higher price due to alloying | Lower price, widely available |

| Applications | Food processing, medical tools, appliances | Construction, automotive, heavy machinery |

Understanding Stainless Steel and Carbon Steel

Stainless steel contains a minimum of 10.5% chromium, which provides exceptional corrosion resistance and durability, making it ideal for applications requiring long-term exposure to moisture or chemicals. Carbon steel, composed primarily of iron with a higher carbon content (up to 2%), offers superior strength and hardness but lacks inherent corrosion resistance, necessitating protective coatings for outdoor or humid environments. Understanding the distinct alloy compositions and mechanical properties of stainless steel and carbon steel is essential for selecting the appropriate material in construction, manufacturing, or tooling industries.

Composition Differences: Stainless Steel vs Carbon Steel

Stainless steel contains a minimum of 10.5% chromium, which forms a passive layer of chromium oxide on the surface, providing corrosion resistance and preventing rust. Carbon steel primarily consists of iron and carbon, with carbon content typically ranging from 0.05% to 2.0%, but it lacks significant amounts of chromium or other alloying elements that enhance corrosion resistance. The presence of chromium in stainless steel not only improves durability but also impacts its weldability and maintenance compared to carbon steel.

Corrosion Resistance: Which Is Better?

Stainless steel offers superior corrosion resistance due to its high chromium content, typically above 10.5%, which forms a passive oxide layer preventing rust and staining. Carbon steel lacks this protective layer and is more prone to corrosion, especially in humid or saline environments unless coated or treated. For applications requiring durability and minimal maintenance in corrosive conditions, stainless steel is the better choice.

Strength and Durability Comparison

Stainless steel offers superior corrosion resistance and maintains strength in harsh environments, making it highly durable for applications exposed to moisture and chemicals. Carbon steel generally exhibits higher tensile strength and hardness, providing excellent wear resistance and mechanical performance under heavy loads. While carbon steel can be prone to rust, its overall durability is enhanced with protective coatings, whereas stainless steel intrinsically combines strength with longevity in diverse conditions.

Common Applications of Stainless Steel and Carbon Steel

Stainless steel, prized for its corrosion resistance, is commonly used in kitchen appliances, medical instruments, and chemical processing equipment where durability and hygiene are critical. Carbon steel, known for its strength and affordability, is widely applied in construction, automotive parts, and heavy machinery manufacturing. Both materials serve essential roles in industrial and consumer products, chosen based on specific mechanical properties and environmental resistance requirements.

Cost Analysis: Stainless Steel vs Carbon Steel

Carbon steel offers a significantly lower initial cost compared to stainless steel, making it a cost-effective option for budget-sensitive projects. Stainless steel, while more expensive upfront, provides superior corrosion resistance and longer lifespan that can reduce maintenance and replacement costs over time. Evaluating total ownership costs is crucial, as stainless steel's durability may offset its higher purchase price in applications exposed to harsh environments.

Machinability and Workability Factors

Stainless steel offers superior corrosion resistance but generally exhibits lower machinability than carbon steel due to its higher work hardening rate and toughness. Carbon steel provides better workability and easier machining, attributed to its lower alloying content and softer microstructure. Selection depends on application requirements, balancing stainless steel's durability with carbon steel's efficiency in fabrication processes.

Maintenance Requirements and Longevity

Stainless steel requires minimal maintenance due to its corrosion-resistant properties, making it ideal for environments exposed to moisture and chemicals, which extends its longevity significantly. Carbon steel demands regular upkeep such as painting or coating to prevent rust and corrosion, impacting its durability in harsh conditions. While stainless steel generally offers a longer lifespan, carbon steel can perform well with proper maintenance and is often chosen for its strength and cost-effectiveness.

Environmental Impact and Sustainability

Stainless steel offers superior corrosion resistance, reducing the need for frequent replacement and lowering long-term waste, which supports sustainability goals. Carbon steel, while more energy-intensive to produce due to higher carbon content and less corrosion resistance, generally has a lower initial environmental footprint because of its simpler alloy composition. Recycling both metals significantly reduces environmental impact, but stainless steel's alloy elements like chromium and nickel require careful management to minimize ecological harm.

Choosing the Right Steel for Your Project

Stainless steel offers superior corrosion resistance, making it ideal for projects exposed to moisture or chemicals, whereas carbon steel provides greater strength and is more cost-effective for structural applications. Selecting the right steel depends on environmental conditions, mechanical requirements, and budget constraints. Evaluating factors such as tensile strength, corrosion resistance, and weldability ensures optimal performance and project longevity.

Stainless Steel vs Carbon Steel Infographic

materialdif.com

materialdif.com