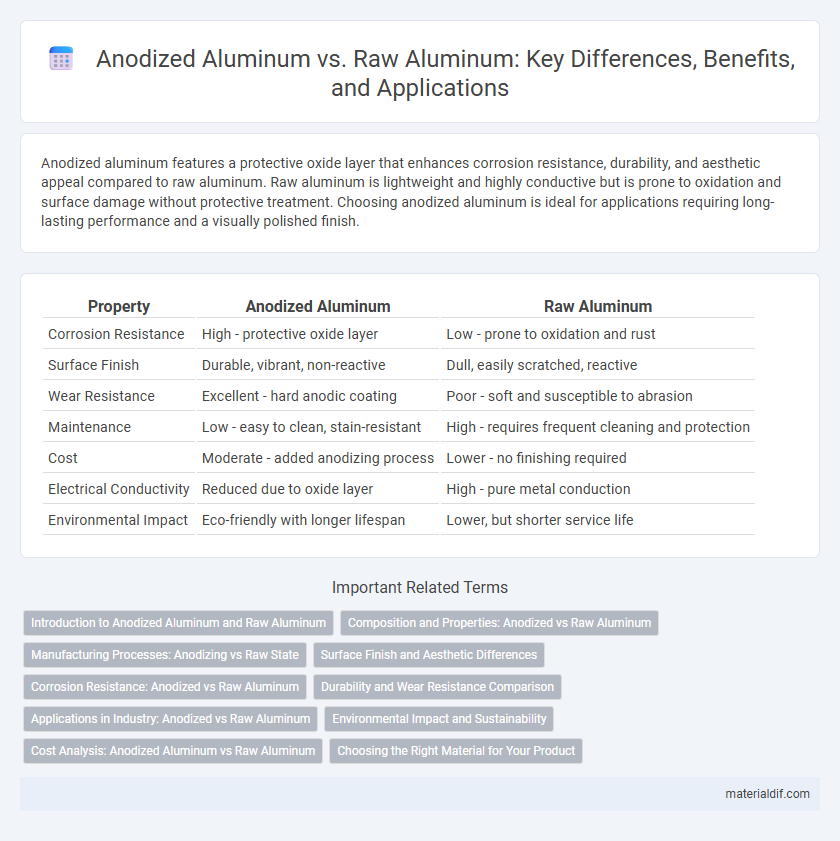

Anodized aluminum features a protective oxide layer that enhances corrosion resistance, durability, and aesthetic appeal compared to raw aluminum. Raw aluminum is lightweight and highly conductive but is prone to oxidation and surface damage without protective treatment. Choosing anodized aluminum is ideal for applications requiring long-lasting performance and a visually polished finish.

Table of Comparison

| Property | Anodized Aluminum | Raw Aluminum |

|---|---|---|

| Corrosion Resistance | High - protective oxide layer | Low - prone to oxidation and rust |

| Surface Finish | Durable, vibrant, non-reactive | Dull, easily scratched, reactive |

| Wear Resistance | Excellent - hard anodic coating | Poor - soft and susceptible to abrasion |

| Maintenance | Low - easy to clean, stain-resistant | High - requires frequent cleaning and protection |

| Cost | Moderate - added anodizing process | Lower - no finishing required |

| Electrical Conductivity | Reduced due to oxide layer | High - pure metal conduction |

| Environmental Impact | Eco-friendly with longer lifespan | Lower, but shorter service life |

Introduction to Anodized Aluminum and Raw Aluminum

Anodized aluminum undergoes an electrochemical process that enhances its surface by creating a durable, corrosion-resistant oxide layer, making it ideal for applications requiring increased protection and aesthetic appeal. Raw aluminum is the unprocessed metal known for its lightweight and excellent thermal conductivity but lacks the enhanced durability and abrasion resistance provided by anodizing. Understanding the differences between anodized and raw aluminum is essential for choosing the right material in aerospace, automotive, and construction industries.

Composition and Properties: Anodized vs Raw Aluminum

Anodized aluminum features a surface layer of aluminum oxide formed through an electrochemical process, enhancing corrosion resistance, surface hardness, and wear durability compared to raw aluminum, which lacks this protective coating. Raw aluminum is composed primarily of aluminum with trace amounts of silicon, iron, copper, and magnesium, offering excellent malleability and thermal conductivity but reduced surface protection. The anodization process increases oxide layer thickness from about 3-5 nanometers in raw aluminum to up to 25 microns, significantly improving resistance to oxidation and surface abrasion.

Manufacturing Processes: Anodizing vs Raw State

Anodizing aluminum involves an electrochemical process that enhances corrosion resistance and surface hardness by forming a durable oxide layer, while raw aluminum remains untreated with a softer, more reactive surface prone to oxidation. The anodizing process includes immersion in an acid electrolyte solution and application of an electric current, resulting in increased durability and aesthetic options such as color finishes. Raw aluminum is typically used in applications where further surface treatment is unnecessary or where post-manufacturing customization is required.

Surface Finish and Aesthetic Differences

Anodized aluminum features a durable, corrosion-resistant surface with enhanced color options and a matte to glossy finish, providing superior aesthetic appeal compared to raw aluminum's natural, dull gray look. The anodization process creates a thicker oxide layer that improves scratch resistance and allows for vibrant, long-lasting finishes in various colors. Raw aluminum's untreated surface is prone to oxidation and tarnishing, resulting in a less uniform and more industrial appearance.

Corrosion Resistance: Anodized vs Raw Aluminum

Anodized aluminum exhibits significantly enhanced corrosion resistance compared to raw aluminum due to its thick, protective oxide layer formed during the anodizing process. This oxide layer acts as a barrier against moisture and environmental factors, preventing oxidation and surface degradation common in raw aluminum. Raw aluminum, while naturally forming a thin oxide layer, lacks the durability and protective qualities of anodized aluminum, making it more susceptible to corrosion in harsh environments.

Durability and Wear Resistance Comparison

Anodized aluminum exhibits superior durability and wear resistance compared to raw aluminum due to the electrochemical oxidation process that creates a hard, protective oxide layer. This anodic coating significantly enhances resistance to corrosion, abrasion, and surface scratching, extending the metal's lifespan in harsh environments. Raw aluminum lacks this protective barrier, making it more prone to oxidation, surface wear, and mechanical damage under similar conditions.

Applications in Industry: Anodized vs Raw Aluminum

Anodized aluminum's enhanced corrosion resistance and surface hardness make it ideal for aerospace, automotive, and architectural applications where durability and aesthetic appeal are critical. Raw aluminum, with its lightweight and high thermal conductivity, is preferred in electrical components, heat exchangers, and structural frameworks where surface finish and corrosion resistance are less critical. Industry sectors prioritize anodized aluminum for protective coatings and decorative finishes, while raw aluminum is favored for cost-effective manufacturing and components requiring further surface treatment.

Environmental Impact and Sustainability

Anodized aluminum offers enhanced corrosion resistance and a longer lifespan compared to raw aluminum, reducing the need for frequent replacement and lowering overall environmental impact. The anodizing process, which uses an electrochemical treatment, creates a durable oxide layer that is non-toxic and fully recyclable, supporting sustainability goals. Raw aluminum production is energy-intensive with significant greenhouse gas emissions, while anodized aluminum's extended durability contributes to resource conservation and waste reduction.

Cost Analysis: Anodized Aluminum vs Raw Aluminum

Anodized aluminum typically incurs higher upfront costs than raw aluminum due to the additional electrochemical process required for coating. However, anodizing enhances corrosion resistance and surface durability, potentially reducing long-term maintenance and replacement expenses. When evaluating total cost of ownership, anodized aluminum may prove more cost-effective in environments exposed to wear or harsh conditions.

Choosing the Right Material for Your Product

Anodized aluminum offers enhanced corrosion resistance, increased surface hardness, and improved aesthetic appeal compared to raw aluminum, making it ideal for products exposed to harsh environments or requiring long-term durability. Raw aluminum, while lighter and more cost-effective, is prone to oxidation and surface damage, which can compromise product longevity and performance. Selecting anodized aluminum for your product ensures greater protection and visual quality, especially in industries like aerospace, automotive, and construction where material resilience is critical.

Anodized Aluminum vs Raw Aluminum Infographic

materialdif.com

materialdif.com