Die casting offers high-speed production and excellent dimensional accuracy, making it ideal for large volumes of metal pet components requiring durability and intricate details. Investment casting provides superior surface finish and allows for complex geometries with tight tolerances, suitable for custom or small-batch metal pet parts. Choosing between die casting and investment casting depends on production scale, design complexity, and cost considerations in metal pet manufacturing.

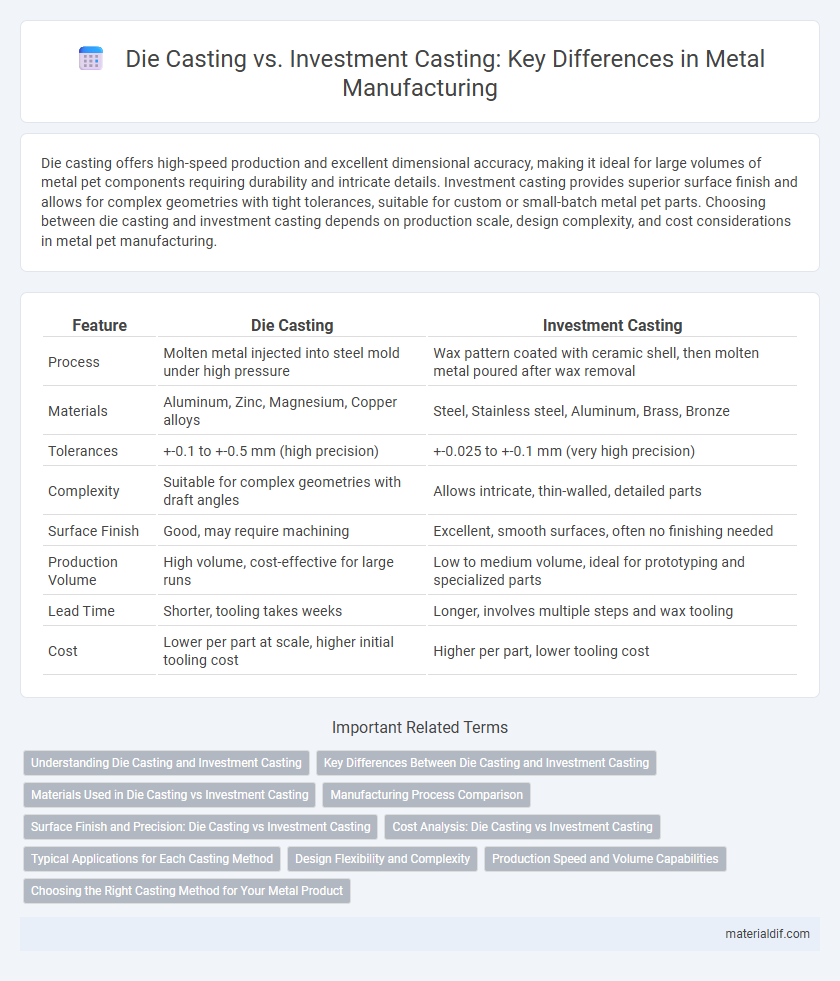

Table of Comparison

| Feature | Die Casting | Investment Casting |

|---|---|---|

| Process | Molten metal injected into steel mold under high pressure | Wax pattern coated with ceramic shell, then molten metal poured after wax removal |

| Materials | Aluminum, Zinc, Magnesium, Copper alloys | Steel, Stainless steel, Aluminum, Brass, Bronze |

| Tolerances | +-0.1 to +-0.5 mm (high precision) | +-0.025 to +-0.1 mm (very high precision) |

| Complexity | Suitable for complex geometries with draft angles | Allows intricate, thin-walled, detailed parts |

| Surface Finish | Good, may require machining | Excellent, smooth surfaces, often no finishing needed |

| Production Volume | High volume, cost-effective for large runs | Low to medium volume, ideal for prototyping and specialized parts |

| Lead Time | Shorter, tooling takes weeks | Longer, involves multiple steps and wax tooling |

| Cost | Lower per part at scale, higher initial tooling cost | Higher per part, lower tooling cost |

Understanding Die Casting and Investment Casting

Die casting involves forcing molten metal into a mold cavity under high pressure, producing precise and complex metal parts rapidly with excellent surface finish and dimensional accuracy, commonly used for aluminum, zinc, and magnesium alloys. Investment casting, also known as lost-wax casting, creates intricate shapes with tight tolerances by forming a wax pattern coated with refractory ceramic, which is then melted away to form the mold, suitable for stainless steel, superalloys, and non-ferrous metals. Both processes offer distinct advantages in metal manufacturing: die casting excels in high-volume production with low per-unit cost, while investment casting provides superior detail and versatility for complex geometries.

Key Differences Between Die Casting and Investment Casting

Die casting uses high-pressure injection of molten metal into steel molds, enabling rapid production of complex, high-volume parts with excellent dimensional consistency, while investment casting involves creating wax patterns coated with ceramic shells for intricate, precise components with superior surface finish and minimal machining. Die casting typically suits non-ferrous metals like aluminum, zinc, and magnesium, delivering thin-walled, lightweight parts, whereas investment casting supports a broader range of alloys, including stainless steel and superalloys, for high-strength, corrosion-resistant applications. Cost-efficiency favors die casting in mass production due to reusable molds, but investment casting excels in lower volumes and complex geometries where tooling costs and lead times are less critical.

Materials Used in Die Casting vs Investment Casting

Die casting commonly utilizes non-ferrous metals such as aluminum, zinc, magnesium, and copper alloys due to their excellent fluidity and thermal conductivity, enabling high-volume production with precise dimensional tolerances. Investment casting accommodates a wider range of materials, including ferrous metals like stainless steel, carbon steel, and superalloys, which allow for intricate shapes and superior mechanical properties in complex, high-performance components. The material selection in die casting favors rapid solidification and mass production efficiency, whereas investment casting prioritizes material diversity and fine detail reproduction for specialized industrial applications.

Manufacturing Process Comparison

Die casting involves injecting molten metal into a steel mold under high pressure, enabling rapid production with excellent dimensional accuracy and surface finish, ideal for high-volume manufacturing. Investment casting, also known as lost-wax casting, uses wax patterns coated with ceramic shells to form complex geometries with superior detail and minimal machining, suited for intricate or low-volume parts. Die casting generally offers faster cycle times and lower per-unit costs, while investment casting excels in intricate designs and a wider range of alloy compatibility.

Surface Finish and Precision: Die Casting vs Investment Casting

Die casting offers a smoother surface finish with tighter dimensional tolerances, making it ideal for high-volume production of intricate metal parts. Investment casting provides superior precision and complexity for detailed components, delivering excellent surface quality with minimal machining required. Both methods optimize surface finish and accuracy, but investment casting excels in achieving intricate geometries while die casting excels in consistency and speed.

Cost Analysis: Die Casting vs Investment Casting

Die casting generally offers lower per-unit costs than investment casting due to faster production cycles and higher automation, making it ideal for large-volume manufacturing of metal components. Investment casting involves higher initial tooling expenses and labor costs but provides superior dimensional accuracy and complex geometries, justifying its use for precision parts in aerospace and medical industries. For cost analysis, die casting reduces expenses through material efficiency and speed, while investment casting incurs higher costs but adds value with detailed surface finishes and tight tolerances.

Typical Applications for Each Casting Method

Die casting is commonly used for manufacturing automotive components, electrical housings, and consumer electronics due to its high production speed and ability to create complex shapes with tight tolerances. Investment casting excels in producing aerospace parts, medical devices, and intricate jewelry where precision and surface finish are critical. The choice between die casting and investment casting depends on the specific application requirements, such as volume, detail, and mechanical properties.

Design Flexibility and Complexity

Die casting offers high design flexibility with the ability to produce complex shapes featuring thin walls and intricate details due to high-pressure metal injection. Investment casting excels in creating highly intricate geometries with exceptional surface finishes and fine details that are difficult to achieve through other methods. Both methods support complex designs, but investment casting provides greater precision for small, detailed components while die casting is favored for larger, structurally robust parts.

Production Speed and Volume Capabilities

Die casting offers rapid production speeds with cycle times often under a minute, making it ideal for high-volume manufacturing of complex metal parts, especially aluminum and zinc alloys. Investment casting, while slower with longer cycle times due to wax pattern creation and ceramic mold processing, excels in producing smaller batches of intricate, high-precision components with excellent surface finishes. For applications demanding mass production and quick turnaround, die casting provides superior efficiency and volume capabilities compared to the more time-intensive investment casting process.

Choosing the Right Casting Method for Your Metal Product

Die casting offers high-volume production with excellent dimensional accuracy and smooth surface finishes, ideal for lightweight, complex aluminum or zinc parts. Investment casting provides superior detail and versatility for intricate designs, suitable for small batches and high-temperature metals like stainless steel or titanium. Selecting the right casting method depends on factors such as production volume, metal type, complexity, and required surface quality.

Die Casting vs Investment Casting Infographic

materialdif.com

materialdif.com