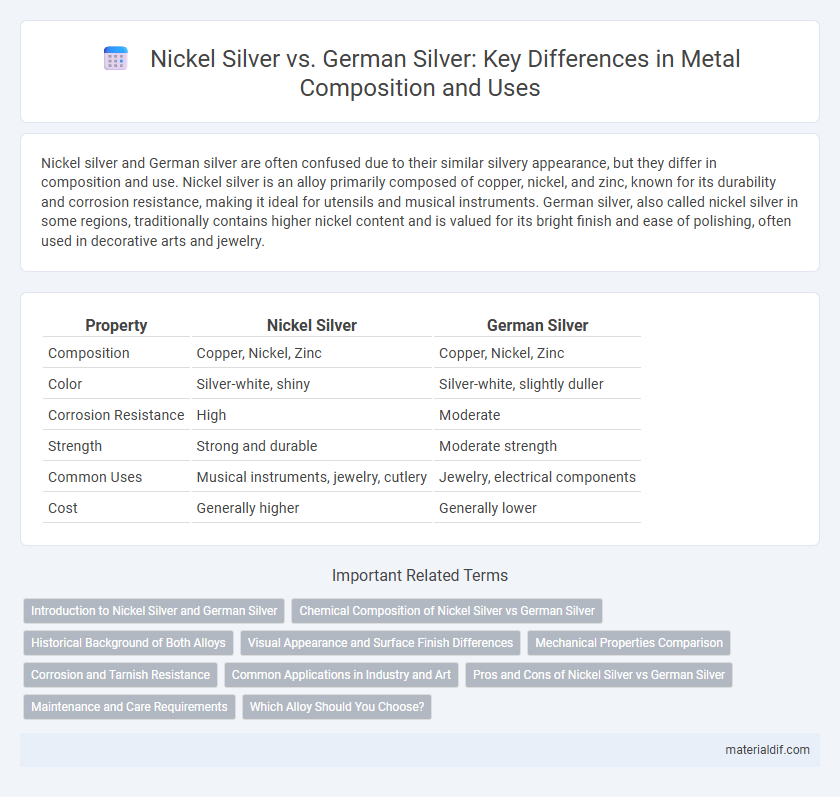

Nickel silver and German silver are often confused due to their similar silvery appearance, but they differ in composition and use. Nickel silver is an alloy primarily composed of copper, nickel, and zinc, known for its durability and corrosion resistance, making it ideal for utensils and musical instruments. German silver, also called nickel silver in some regions, traditionally contains higher nickel content and is valued for its bright finish and ease of polishing, often used in decorative arts and jewelry.

Table of Comparison

| Property | Nickel Silver | German Silver |

|---|---|---|

| Composition | Copper, Nickel, Zinc | Copper, Nickel, Zinc |

| Color | Silver-white, shiny | Silver-white, slightly duller |

| Corrosion Resistance | High | Moderate |

| Strength | Strong and durable | Moderate strength |

| Common Uses | Musical instruments, jewelry, cutlery | Jewelry, electrical components |

| Cost | Generally higher | Generally lower |

Introduction to Nickel Silver and German Silver

Nickel silver and German silver are metal alloys primarily composed of copper, nickel, and zinc, known for their silvery appearance despite containing no actual silver. Nickel silver typically offers enhanced corrosion resistance and a brighter finish, making it popular in musical instruments, cutlery, and jewelry. German silver, often used in antiques and decorative items, has a slightly higher copper content that gives it a warmer tone and distinctive patina over time.

Chemical Composition of Nickel Silver vs German Silver

Nickel silver, also known as German silver, typically consists of copper, nickel, and zinc in varying proportions, usually around 60% copper, 20% nickel, and 20% zinc. The primary difference lies in the specific nickel content and trace elements, where some German silver alloys may include small amounts of manganese or iron to enhance durability and corrosion resistance. Both alloys lack actual silver despite their names and share similar bright, silvery appearances due to their chemical composition.

Historical Background of Both Alloys

Nickel silver, also known as German silver, originated in the early 19th century as an alloy of copper, nickel, and zinc designed to imitate sterling silver without the precious metal's cost. The term "German silver" reflects the alloy's development in Germany, where it gained prominence during the industrial revolution for its durability and silver-like appearance. Both names refer to the same alloy, historically significant in manufacturing household items, musical instruments, and jewelry across Europe and America.

Visual Appearance and Surface Finish Differences

Nickel silver and German silver both exhibit a silvery appearance, but nickel silver typically has a brighter, more lustrous finish due to its higher nickel content. German silver, an alloy of copper, nickel, and zinc, often presents a slightly warmer, matte surface finish with subtle yellowish tones. The visual distinction is evident in applications like musical instruments and decorative items, where nickel silver's reflective quality contrasts with the muted sheen of German silver.

Mechanical Properties Comparison

Nickel Silver, an alloy composed primarily of copper, nickel, and zinc, offers superior tensile strength and corrosion resistance compared to German Silver, which contains a higher copper content with nickel and zinc in varied proportions. The enhanced hardness and elasticity of Nickel Silver make it ideal for applications requiring durable mechanical performance, while German Silver tends to exhibit greater malleability and ease of machining due to its softer composition. Both alloys provide good wear resistance, but Nickel Silver maintains structural integrity better under stress and high-temperature conditions.

Corrosion and Tarnish Resistance

Nickel silver, an alloy primarily composed of copper, nickel, and zinc, offers superior corrosion resistance compared to German silver due to its higher nickel content, which forms a protective oxide layer reducing tarnish. German silver, also known as nickel silver or cupronickel, typically contains a higher copper percentage, making it more prone to tarnishing and surface oxidation over time. The enhanced durability of nickel silver in harsh environments makes it a preferred choice for applications requiring long-lasting, tarnish-resistant metal components.

Common Applications in Industry and Art

Nickel silver, an alloy composed mainly of copper, nickel, and zinc, is widely used in electrical components, musical instruments, and cutlery due to its corrosion resistance and aesthetic appeal. German silver, despite its name, contains no actual silver and is often employed in jewelry, decorative arts, and architectural hardware for its bright, silvery finish and ease of fabrication. Both alloys serve critical roles in artistic metalworking and industrial applications where durability and appearance are essential.

Pros and Cons of Nickel Silver vs German Silver

Nickel silver, composed mainly of copper, nickel, and zinc, offers excellent corrosion resistance and a bright, silvery appearance that is ideal for decorative applications but can be more expensive than German silver. German silver, an alloy of copper, nickel, and zinc as well, tends to be softer and less durable, making it easier to work with for intricate designs yet less resistant to tarnishing and wear. While nickel silver provides superior strength and longevity, German silver is favored for its malleability and cost-effectiveness in manufacturing.

Maintenance and Care Requirements

Nickel silver, composed of copper, nickel, and zinc, requires regular polishing to prevent tarnishing and maintain its bright, silvery appearance, while German silver--an alloy containing copper, nickel, and zinc as well--also needs frequent cleaning but tends to develop a patina over time that some users find desirable. Both metals are resistant to corrosion and oxidation, yet using mild soap and water for cleaning, followed by thorough drying, effectively preserves their surface integrity. Proper storage in a dry environment minimizes exposure to moisture and air, significantly reducing the frequency of maintenance for each alloy.

Which Alloy Should You Choose?

Nickel silver and German silver are both copper-based alloys containing nickel and zinc, but nickel silver typically features a higher nickel content, resulting in greater corrosion resistance and a brighter, more durable finish. German silver, known for its slightly softer composition, offers superior malleability and a warm, antique appearance ideal for decorative applications. Choose nickel silver for jewelry or instruments requiring long-lasting shine and toughness, while German silver suits artistic projects needing easy shaping and a vintage look.

Nickel Silver vs German Silver Infographic

materialdif.com

materialdif.com